Modular Advantage Magazine

In each bi-monthly issue, Modular Advantage Magazine explores a specific modular construction topic and features interviews and articles along with industry news, updates from the Modular Building Institute and its members, modular case studies, and upcoming industry events. This construction trade magazine is a valuable resource for anyone interested in commercial modular construction.

While printed copies are mailed free to MBI members, we have partnered with PBC Today and BD+C magazines to send digital versions of the magazine to 300,000+ industry professionals around the world, including architects, engineers, developers, and general contractors in the United States, Canada, the United Kingdom, and Europe. Free digital versions are also available by subscribing to MBI's weekly e-newsletter..

SPONSORED BY

Latest Articles & Interviews

Samantha Taylor: Leading the (Modular) Design of Tomorrow

“With modern technology and the way we’ve all embraced things like BIM, file sharing, and video conferencing since COVID, it’s easy to collaborate with companies in Austria, or Singapore, or anywhere else in the world.”

Greg DeLeon: Military Engineering to Modular Design

Greg DeLeon, a structural engineer at ISE Structural Engineers in Temecula, California, can tell you not only how large a beam needs to be to support a house, but also how much explosives you’ll need to take it down, thanks to his unique combination of professional and military experience.

To Remake North Minneapolis, Devean George Swaps Basketball for Buildings

He’s lived in Los Angeles, Dallas, and San Francisco (to name a few). He’s delivered championships with the Los Angeles Lakers and made career-defining moves with the Dallas Mavericks and the Golden State Warriors. No matter the wins, the championships, or even the seemingly impossible 3-pointers, Devean George has always returned to where it all started for him: Minneapolis.

Chelsi Tryon: Making the World a Better Place

For Chelsi Tryon, Director of Environmental, Social, and Governance (ESG) for WillScot Mobile Mini, nothing is more enjoyable than increasing the

company’s sustainability efforts while simultaneously doing her bit to save the environment.

Joshua Hart: Pushing Boundaries

Joshua Hart, P.E., vice president at Modular

Solutions, can sum up his job responsibilities in one sentence: “I do whatever needs to be done.” Hart thrives on the variety and the opportunity to be involved in every aspect of the company. And it shows! You might say Hart has come full circle.

Jamie Metzger: From Construction to Apparel and Back Again

Growing up in a blue-collar city like Edmonton, Alberta, Canada, it’s no surprise that Jamie Metzger spent some time working labor jobs on construction sites. It’s one of the most common summer jobs in the city. But that’s probably the last predictable thing about this particular story.

Victor Masso: Expanding Modular in Puerto Rico

Victor Masso joined 2 Go Storage, a company started by his grandfather and father, in 2018 to develop a modular building division in the wake of the devastation caused by Hurricane Maria in 2017. Prior to joining the company, he had worked in the industry for about four years focusing on pharmaceutical, commercial, and government projects.

Eliyah Ryals: Finding the Perfect Fit

It’s not common for people to find their perfect career fit straight out of college. It’s even less common to find it in the town you grew up in. But that’s exactly what happened when Eliyah Ryals was told about vacancies at Panel Built and made the decision to apply.

Through It All, It’s Still About the Workers

By February 2024, the number of available, unfilled construction job openings had reached an all-time high. At some point, interest rates will fall, creating another surge in demand for such workers. In short, solving the nation’s skilled worker shortage issue has never been more important.

Navigating Insurance Challenges in the Modular Construction Industry

Utilizing practical written minimum insurance and indemnity requirements, along with monitoring certificates of insurance by someone who has COI training will not yield a perfect risk transfer strategy, but the exposure will be managed much better than it likely is currently.

Digitalizing Your Products for Seamless Integration into Modular Projects

KOPE enables products to carry information on product data, drawing templates, links to other products and systems, and the rules on how they should be configured and arranged in projects. We need to get rid of moments where decisions are translated either from one skill set to another and from one file type to another. The data that informs you should also be the data that gets passed along to the next link in the chain.

How to Fail at Delivering a Modular Project

Success can involve challenges, but it often provides valuable experiences that can be replicated in future endeavors. Failures can be categorized into two types: those that transform into successes through perseverance, and those that are resolved during the project but serve as valuable lessons to avoid in the future. Here are a few to avoid on your next project:

Developing the Offsite Workforce

Workforce development and labor challenges continue to be a topic of discussion and area of opportunity for the construction industry, and during this year’s World of Modular conference in Orlando, The Workforce Development Lounge (“The Lounge”), hosted by Momentum Innovation Group, was launched to provide a space for attendees to network and collaborate on labor solutions and resources.

Career Lessons Learned: Interviews with Industry Professionals

What lessons have mid-career and veteran industry professionals learned over the course of their careers? How has the commercial modular construction industry changed over time, what needs to happen to keep the industry growing, and what keeps them invested?

Current Issue

This issue of Modular Advantage profiles some of the many talented young professionals in the modular construction industry. Across the permanent and relocatable building sectors, from backgrounds ranging from the military to fashion to their currents roles ranging from designers to sales managers, these individuals represent the new generation of modular building innovation.

Featured Modular Building Case Studies

Panel Built Provides Custom Modular Enclosure for Major Beverage Manufacturer

The challenge was twofold. Firstly, Panel Built needed to create a spacious enclosure that could accommodate a large facility crane. This enclosure required a design that provided ample storage space and integrated seamlessly with the existing infrastructure. Secondly, the structure needed to incorporate office space that offered personnel an unimpeded, 360-degree view of the factory floor.

Fire Station 67

Fire Station 67 is designed in direct response to the climate crisis, the increasing threat of wildfires, and the needs to the Rancho Mission Viejo community. Prefabricated off-site and assembled from 10 modules, the 4,667-square-foot fire station is a modular design with the ability to reconfigure the structure into something new in the future.

Maceo May

Maceo May is a six-story, all-electric modular construction, affordable housing development located on Treasure Island in San Francisco Bay. The climate-responsive design provides 104 homes for formerly homeless veterans and their families with a strong focus on decarbonization, resilience and wellness. The apartment building offers 1 on-site manager’s unit, and a mix of 24 studio, 47 one-bedroom and 34 two-bedroom units.

The Sphere Made Possible with Exterior Wall Panels

This one-of-a-kind structure required one-of-a-kind building materials and exterior cladding that could accommodate the atypical geometries, project timelines, and significant daily foot traffic. Offsite construction, in the form of Dryvit’s Outsulite prefabricated panels of continuous insulation (CI), was the key method for streamlining the façade installation and ensuring quality control for the difficult building connections.

Modular Construction for Financial Viability: The Norwalk Project Case Study

The Norwalk project serves as a prime example of how Offsite Modular Construction, in collaboration with Architects, Consultants/Engineers, General Contractors (GC), and Mechanical, Electrical, Plumbing, and Fire Protection (MEP/FP) Subcontractors, can make projects financially feasible by closely working with the Owner/Developer under an Integrated Project Delivery (IPD) approach.

STAAT MOD Patient Bed Expansion at M Health Fairview – St. John’s Hospital

Construction firm The Boldt Company, and interdisciplinary design firm, HGA were engaged by St. John’s Hospital to deliver a 16-bed ICU patient observation wing onto the existing facility, built to over 90 percent completion offsite in Appleton, Wisc., then seamlessly transported and installed on the St. John’s campus – the first of its kind in the state of Minnesota.

Offsite Modular Construction Builds and Installs 12 New Classrooms for Westlake Academy in 100 Days

OMC utilized modular construction techniques to manufacture two brand new permanent 6,400-square-foot modular buildings, each housing six classrooms. The process included innovative design features for safety, durability, environmental sustainability, integrated technology enhancements, and health-oriented construction.

Formula 1 Race, Las Vegas, Nevada

In partnership with InProduction, Phoenix Modular Elevator (PME) designed, manufactured, and installed seven modular elevators for the F1 Grand Prix race in Las Vegas, Nevada. To minimize space, the design utilized machine roomless (MRL) hydraulic elevators, eliminating the need for separate machine rooms for each elevator. Instead, using the MRL design, the machine room equipment is built into the hoistway, and accessed via a small door on the side.

Silverking Student Housing, Selkirk College

ROC Modular was proud to deliver a much-needed new permanent modular Student Housing Residence for Selkirk College, located at the Silverking Campus in Nelson BC. The project is a 3-storey, 12-module 38-student bed building with a mass-timber main common area for student amenities.

Parkhurst Elementary School Classroom Additions

The Parkhurst Elementary School in Winchester, MA, has recently undergone an expansion of 13,074 square feet. Due to renovations at the neighboring Lynch School, students were temporarily relocated to Parkhurst. Modular construction was chosen as the preferred method to accommodate the influx of students and prepare for the start of the 2023-2024 school year.

VBC Chooses MAESTRO SMART 9 HP

Volumetric Building Companies (VBC), a global leader in the construction sector with a focus on building the future through volumetric modular techniques, choose the Maestro Smart 9 Heat Pump as their ideal comfort solution to heat and cool their modular housing project in Philadelphia, PA, consisting of 60 modular housing units.

16’ x 37’ Welded Substation Enclosure

Instead of sourcing a new transformer, which would have taken over 100 weeks and cost several million dollars, Raytheon Technologies turned to Panel Built Inc. for a modular solution. Panel Built designed a 16’ x 37’ prefabricated enclosure that could be delivered to Guam in two pieces. Once it was put together, it was lowered over the transformer.

Temporary Visitors Center at Antietam National Battlefield Park

Antietam National Battlefield Park, a revered site listed on the U.S. National Register of Historic Places, presented unique challenges demanding meticulous preservation efforts. The paramount goal was to ensure minimal disruption to the sacred grounds surrounding the new modular building.

Wraptite Airtightness Protection for Northampton School for Boys

The Wraptite external air barrier system from the A. Proctor Group has been chosen for its high-performance, airtight insulation for a Department for Education (DfE) funded project of the offsite construction of Northampton School for Boys Multi-Academy Trust.

University Temporary Modular Student Housing— Ettrick, VA

Modular Genius, Inc. designed and built three temporary modular dormitory complexes featuring 134 dorm rooms, totaling 49,632 sq. ft. All three modular dorms feature a shared laundry room, kitchen and lounge area, showers, and restrooms for residents.

Hage’s Badehotel — Case Study — Denmark

For this project, Forta PRO delivered 72 buildings, 144 modules, with 5,200 m2 of gross modular area. With final onsite completion in June 2023, it provides exceptional long-stay accommodation in a stunning and serene environment.

355 Sango Court Case Study

The logic-intensive preconstruction method demanded of automated modular brought extra benefits to the Sango Court project. Autovol had worked side by side with preconstruction innovator Prefab Logic to create a digital twin modeling approach and a sprint process as advanced as the Autovol factory.

Enhancing Building Performance with Wraptite

The Wraptite external air barrier system from A. Proctor Group was installed in combination with the innovative, unique pre-panelized and fully load-bearing Hadley Frame offsite system, which is ideal for developments of low to medium rise structures.

Hearst Elementary School Case Study from Wilmot Modular

Wilmot Modular was hired to consult and provide what was originally a two-story classroom expansion project. The school district wanted the building to match nearby

buildings on the campus, and fit in a steeply graded, small site. There were also budget constraints that had to be managed.

Unity Malmö – New Student Housing in Southern Sweden from Forta PRO

The city of Malmö in southern Sweden is set to welcome a new student housing project Unity Malmö, comprised of 5 building blocks, 450 micro-living apartments, where Forta PRO delivered 269 modules, total of 9,671.9 m2.

Currently an MBI member? Submit your case studies for publication today!

Online Exclusives

Recent Issues

Past Articles

Study Quantifies Modular’s Wood Waste Savings

A recent study commissioned by MBI and carried out at Colorado State University shows that when it comes to optimizing the circular economics of a construction project, modular is the preferred way to build (when compared to traditional ground-up framing techniques).

For True Modular Building, Sustainability is Part of Yesterday, Today, and Tomorrow

For Carel van Duuren, the 71-year-old CEO of True Modular Building, sustainability is more than just his legacy—he’s thinking about the future of society at large. How do you make things infinitely repeatable and simple? How can you make sure you’re contributing to the economy without adding extra waste or using increasingly precious resources? And how can you do this, and quickly?

Newest Line of Container Buildings Broadens Modular’s Reach

Wilmot Modular’s newest line of mobile storage and office buildings is set to expand the reach of modular buildings into remote locations. Their Smart Line – Hybrid Series of container offices and storage buildings provides almost instant connectivity and power in locations that are off-grid, on-grid, or anywhere in between.

Only the Future is at Stake

As the race to reverse global warming intensifies, there is little doubt that modular techniques will be adopted with far greater frequency than has been the case to date. Meanwhile, modular building continues to offer its more traditional benefits to project owners, but the issues facing society are far more pressing these days than simply helping project owners make their pro-formas pencil out.

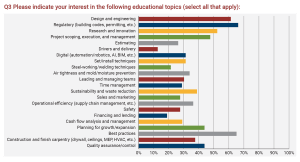

By the Numbers

As part of MBI’s continuing efforts to expand the footprint of the commercial modular construction industry, we launched an intelligence gathering process in mid-September 2023 to collect information on member companies’ challenges and needs with respect to training, professional development, and workforce. The purpose of this process was to identify critical needs to support development of a near- and long-term strategy to address these needs. Here are the results.

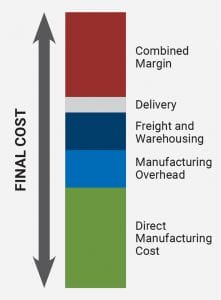

Stop Accepting Non Value Added Building Materials in Modular Supply Chains

Modern CRM and ERP systems make it easier for modular manufacturers to manage complex orders to multiple customers while still providing high levels of customer service and technical support.

Building Green, Living Clean

Modular construction significantly reduces waste generation due to its precision and the controlled environment in which the modules are constructed. According to a report by Waste & Resources Action Program (WRAP), modular construction can reduce waste materials like timber, cardboard, plastics, and concrete by up to 90% compared to traditional construction methods.

A Blanket Approach

Polyisocyanurate, or polyiso, insulation has become a top choice for modular construction. This thermosetting plastic foam board is renowned for its impressive list of attributes:, including high thermal performance, it’s low weight, and more.

Customized & Complex: Inside the Construction of the Nation’s Largest Modular Hospital

With about 100,000 square feet of space on four levels, MODLOGIQ is producing 100% of the hospital’s space off-site in their factory. That includes everything from mechanical, electrical, and plumbing to interior finishes and casework to about an 85% level of completion.

Share Your Story

Do you have a new product, innovative project, or interesting industry news? We want to hear from you! Submit content and inquiries to our communications team at communications@modular.org.

*Not all content submitted will be used. MBI reserves the right to choose content.