Modular Building Project Database

Comprised of modular building projects recently submitted by MBI members around the world, this map—representing only a small sampling of the industry's total output—shows the incredible breadth and diversity of commercial modular buildings.

From high-rise residential towers to sprawling workforce communities to relocatable mobile offices, commercial modular construction projects contribute to every facet of the world's building and infrastructure industries.

Explore the interactive map below using your mouse to zoom in on specific locations, or narrow your search by choosing a building category from the menu on the left side of the map. You can also locate projects by company name using the search field.

Submit Your Modular Project

Help MBI educate developers, architects, and others while showcasing your company’s best projects! Enter your company's modular building project into MBI's database today. For non MBI member projects to appear on the map, those projects must also be submitted into MBI's Awards of Distinction contest.

Data from project entries allows MBI to create the most accurate research and reports possible. And as MBI's interactive project database grows, it will be invaluable to the growth of the commercial modular construction industry.

MBI's Awards of Distinction

The Modular Building Institute's Awards of Distinction represent some of the highest honors awarded in the modular construction industry. Modular building companies self-nominate, while winners are chosen by an independent panel of industry experts and presented at World of Modular, MBI's annual convention and tradeshow.

In addition to prestige, the benefits of winning extend throughout the year. Images of winning and runner-up projects are used in MBI's international marketing efforts—including its popular bi-monthly magazine and highly-ranked website—and, most prominently, MBI’s industry-leading annual reports.

Enter your modular building project today for your chance to earn your well-deserved industry recognition and contribute to MBI's growing collection of modular building case studies.

Explore More Modular Building Case Studies

Geberit In-Wall Systems Makes a New Breed Luxury Room Concept a Reality for International Hotel Brand

Geberit in-wall flush toilet systems for wall-hung toilets are the classics for modern bathroom design. citizenM has specified the Geberit systems into their bathroom walls worldwide as a basis of their bathroom design. This installation is part of the over one million times building owners have installed Geberit systems in their buildings around the globe for over the past 50 years.

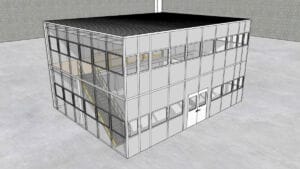

Panel Built Provides Custom Modular Enclosure for Major Beverage Manufacturer

The challenge was twofold. Firstly, Panel Built needed to create a spacious enclosure that could accommodate a large facility crane. This enclosure required a design that provided ample storage space and integrated seamlessly with the existing infrastructure. Secondly, the structure needed to incorporate office space that offered personnel an unimpeded, 360-degree view of the factory floor.

Fire Station 67

Fire Station 67 is designed in direct response to the climate crisis, the increasing threat of wildfires, and the needs to the Rancho Mission Viejo community. Prefabricated off-site and assembled from 10 modules, the 4,667-square-foot fire station is a modular design with the ability to reconfigure the structure into something new in the future.

Maceo May

Maceo May is a six-story, all-electric modular construction, affordable housing development located on Treasure Island in San Francisco Bay. The climate-responsive design provides 104 homes for formerly homeless veterans and their families with a strong focus on decarbonization, resilience and wellness. The apartment building offers 1 on-site manager’s unit, and a mix of 24 studio, 47 one-bedroom and 34 two-bedroom units.

The Sphere Made Possible with Exterior Wall Panels

This one-of-a-kind structure required one-of-a-kind building materials and exterior cladding that could accommodate the atypical geometries, project timelines, and significant daily foot traffic. Offsite construction, in the form of Dryvit’s Outsulite prefabricated panels of continuous insulation (CI), was the key method for streamlining the façade installation and ensuring quality control for the difficult building connections.

Modular Construction for Financial Viability: The Norwalk Project Case Study

The Norwalk project serves as a prime example of how Offsite Modular Construction, in collaboration with Architects, Consultants/Engineers, General Contractors (GC), and Mechanical, Electrical, Plumbing, and Fire Protection (MEP/FP) Subcontractors, can make projects financially feasible by closely working with the Owner/Developer under an Integrated Project Delivery (IPD) approach.

STAAT MOD Patient Bed Expansion at M Health Fairview – St. John’s Hospital

Construction firm The Boldt Company, and interdisciplinary design firm, HGA were engaged by St. John’s Hospital to deliver a 16-bed ICU patient observation wing onto the existing facility, built to over 90 percent completion offsite in Appleton, Wisc., then seamlessly transported and installed on the St. John’s campus – the first of its kind in the state of Minnesota.

Offsite Modular Construction Builds and Installs 12 New Classrooms for Westlake Academy in 100 Days

OMC utilized modular construction techniques to manufacture two brand new permanent 6,400-square-foot modular buildings, each housing six classrooms. The process included innovative design features for safety, durability, environmental sustainability, integrated technology enhancements, and health-oriented construction.

Formula 1 Race, Las Vegas, Nevada

In partnership with InProduction, Phoenix Modular Elevator (PME) designed, manufactured, and installed seven modular elevators for the F1 Grand Prix race in Las Vegas, Nevada. To minimize space, the design utilized machine roomless (MRL) hydraulic elevators, eliminating the need for separate machine rooms for each elevator. Instead, using the MRL design, the machine room equipment is built into the hoistway, and accessed via a small door on the side.