Unity Malmö – New Student Housing in Southern Sweden

The city of Malmö in southern Sweden is set to welcome a new student housing project Unity Malmö, comprised of 5 building blocks, 450 micro-living apartments, where Forta PRO delivered 269 modules, total of 9,671.9 m2.

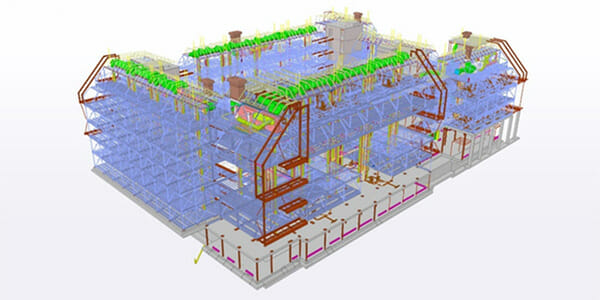

Renderings by Forta PRO of its Unity Malmö modular student housing development.

Forta PRO is a world leading modular construction company, providing advanced state-of-the-art solutions for construction and expansion of apartments, healthcare solutions, hotels, student accommodation, rental apartments and more with minimal disruption to the operations of surrounding facilities. This approach exemplifies what modular construction is, showcasing its efficiency and adaptability.

Unity Malmo project implementation time onsite was from February 1st, 2022 to October 2022, including fully completed installation by August 2022. The building layouts were adapted to modular technology so, as to enable full finishing of the living units in the factory, including preinstalled kitchens along with appliances.

Flexibility of module design and effective collaboration with client allowed to design complex pitched roof modules, preserving living space, which was critical for project design concept and architecture. Technical rooms with inbuilt ventilation aggregates were also produced as modules and installed on the roof-top floor. The project was implemented in collaboration with returning client – general contractor AF Gruppen Sverige and end client UNITY living, which definitely added value to the smooth management and coordination of construction works, moving along the known lines.

Overview

Project UNITY Malmo is a perfect example that modular building does not limit the creativity of designers and a modular building can be impressive and create a unique appearance of the city. By combining the technology of steel modular structure and wooden elements, Forta PRO has achieved not only the flexibility of the technology, but also reduced the size of the construction site, the environmental impact, and labor costs. Installation of modules was implemented in stages divided by separate housing blocks delivery, comprising in total 7 months.

The use of modular technology is a great example of sustainable urban development without compromising the quality and elegance of the exterior of the building.

Why Modular?

The key reason for choosing prefabricated approach for construction of this building complex was a previous successful experience of the client with Forta PRO and modular construction in particular. The quality assurance system, stringent quality control implemented in the factory controlled environment, speed of delivery and shorter onsite construction time have been the main aspects guiding the choice of prefabricated approach.

Trusted partnership and smooth project management has been a definite reassurance for the client to choose offsite construction. 90-95% of total construction volume for this project has been produced offsite, with only staircases and basement constructed onsite. Steel plate façade with different visual aesthetics was installed onsite, with all the insulation and vapor barriers preinstalled in the modules already.

Quality, Speed and Sustainability

UNITY living and Forta PRO considers the implementation of such projects to be extremely important for the creation of sustainable cities. The implementation of projects is faster, the financing is used more efficiently. Total timeline of the project modular part comprised 17 months, starting from module production till handover, which is a fast-track speed considering the project scale exceeding 9,600 m2 of gross modular building area. Speed of installation amounted to 10-12 modules per day.

The project consists of 5 blocks, installation of each was implemented on average in ~ 2 weeks, followed by onsite seal and conceal works and façade installation. Speed of installation allowed for a limited amount of site works, smaller involvement of subcontractors, hence, reduced number of required construction site equipment, containers and site-related utility costs.

The factory control ensures the consumption and quality of materials. Almost all elements can be recycled in the future. In particular, steel structure with an efficiency of more than 90%. With 90-95% of project construction realized offsite, health and safety risks have been substantially minimized while ensuring tight controls and procedures in the controlled factory environment.

UNITY and Forta PRO had to come with multiple solutions how to make each module separately and as well assembled, connected final product. Carefully chosen and tested suppliers. The new solution was created for the roof element, to make building unique and stylish.

Project Outcome

Building complex has been commissioned on 1st of May 2023, and is being gradually occupied by tenants. The building represents an attractive combination of shared communal spaces - winter garden, balconies, terraces attached to modular part of the building.

UNITY living Head of Properties and Facility Management, Claes Brylle Hallqvist commented: “The use of prefabricated modules for combined 238 rooms hotel and 104 lease apartments at Nobelvägen in Malmö has given Unity several advantages. The interior quality of surfaces like painted walls, tiling in bathrooms and wooden floors exceeds what we normally see in traditional in-situ construction as they are produced in a clean and controlled environment at the factory. And from a sustainability perspective we have reduced the footprint as less materials are used in modular construction plus transport and waste can be reduced to a minimum – both on site during construction as well as in the production of the modules. Based on our previous experience with prefabrication we were able to front load the design process to take the advantage of prefabrication even further, as each room was delivered fully equipped with all cabinets, lamps, curtains, beds, bins etc.”

Setting a New Industry Standard!

Aviv Brosilovski, Forta PRO Business Development: “Unity Malmo project was implemented during turbulent times of ongoing Covid and Ukraine war crisis, along with consequential financial risks and cost increases. Despite of that the client and Forta PRO managed to maintain these factors in controlled manner and ensure unhindered project realization. This is a true testimonial to much higher predictability, process and risk management of offsite construction. We are very proud of the completed project results and now being announced as finalist in the International Project of the Year Award!”

More from Modular Advantage

DORÇE Navigates Mountainous Terrain, Extreme Weather to Help Rebuild Türkiye

The February 6 earthquakes in 2023 were enormous. In response, DORÇE moved quickly, obtaining a government bid to help create housing and multipurpose structures—both temporary and permanent—for earthquake victims and laborers hired for reconstruction efforts.

Modern Desert Oasis: Building Reset Hotel the Modular Way

While the off-site construction part of the Reset Hotel project has been carefully controlled and with every necessity close at hand at BECC Modular’s factory in Ontario, Canada, the remote location of the project site has created additional challenges for the on site portion of the build.

Revisiting Yellowstone Canyon Village—a Groundbreaking Modular Construction Feat—Ten Years On

With such a short building period due to impending cold, it made the most sense for park developer Xanterra to pursue modular. Yellowstone’s high visitor traffic also required some odd transportation scheduling, as traffic from the West Yellowstone entrance determined the times when trucks could unload modules. Guerdon was up to the challenge.

Built for Brutal Cold, This Modular Office Building Shines

Houlton, the county seat of Aroostook County, Maine, is a small town with a population of about 6,000 residents. Situated along the border between the U.S. and Canada, what the town is most known for is bitterly cold winters. When the U.S. Border Patrol needed new office space, a modular building approach from Modular Genius offered the perfect solution.

Panel Replacement Adds Years of Life to Navy Vessel

Panel Built, Inc., recently replaced all the wall and roof panels on a two-story US Navy barge deck house that the company had originally installed 30 years ago, giving the vessel new life. Now, the commanding officer of the unit that uses the barge said the difference between the condition and appearance from when the barge left their facility to when the project was complete was beyond his expectations of what was possible.

True Modular Building Seeks to Revolutionize Housing. It’s Next Stop: MBI’s World of Modular Europe

True Modular Building (TMB) specializes in crafting attainable, eco-friendly, and comfortable build-to-rent (BTR) housing with modern designs and customizable features, ensuring that residents feel at home both today and tomorrow.

From Toronto to Suriname: A Global Modular Building Story

When I AM Gold – a Canadian gold mining operation based in Toronto, Ontario – wanted to expand its mining operations in Suriname, it knew it would also need to expand its infrastructure. More specifically, they needed to build a mechanical services compound that would allow their local crews to maintain and equipment critical to their mining operations. They also knew that it would be a challenge.

There Were a “Sea of Challenges” for this Modular, Island Development

Question: Can modular construction be used to build a series of affordable, unique housing buildings, all styled to look like they were built in 1845, on an

island that caters to the wealthy? The answer is, of course, yes, but how the

team at Signature Building Systems and KOH Architecture got there is quite a story.

America’s Construction Economy: A Race Against Time

If the economy has been able to handle higher interest rates thus far, undoubtedly it will be able to manage the lower interest rates to come. But many economists are pointing out that the Federal Reserve may already be too late to the game. While they gradually reduce interest rates, the U.S. economy could quickly decelerate, at least based on theoretical grounds if not on the most recent data releases, culminating in that long-predicted recession. Only time will tell.

Top Five Benefits of Modular Office Space

Modular office spaces are transforming how businesses think about their work environments. These innovative structures offer a mix of flexibility, efficiency, and sustainability, making them a smart choice for companies looking to gain an advantage.