Modular Construction for Financial Viability: The Norwalk Project Case Study

by Konstatin Daskalov, VP of US Operations, Stack Modular

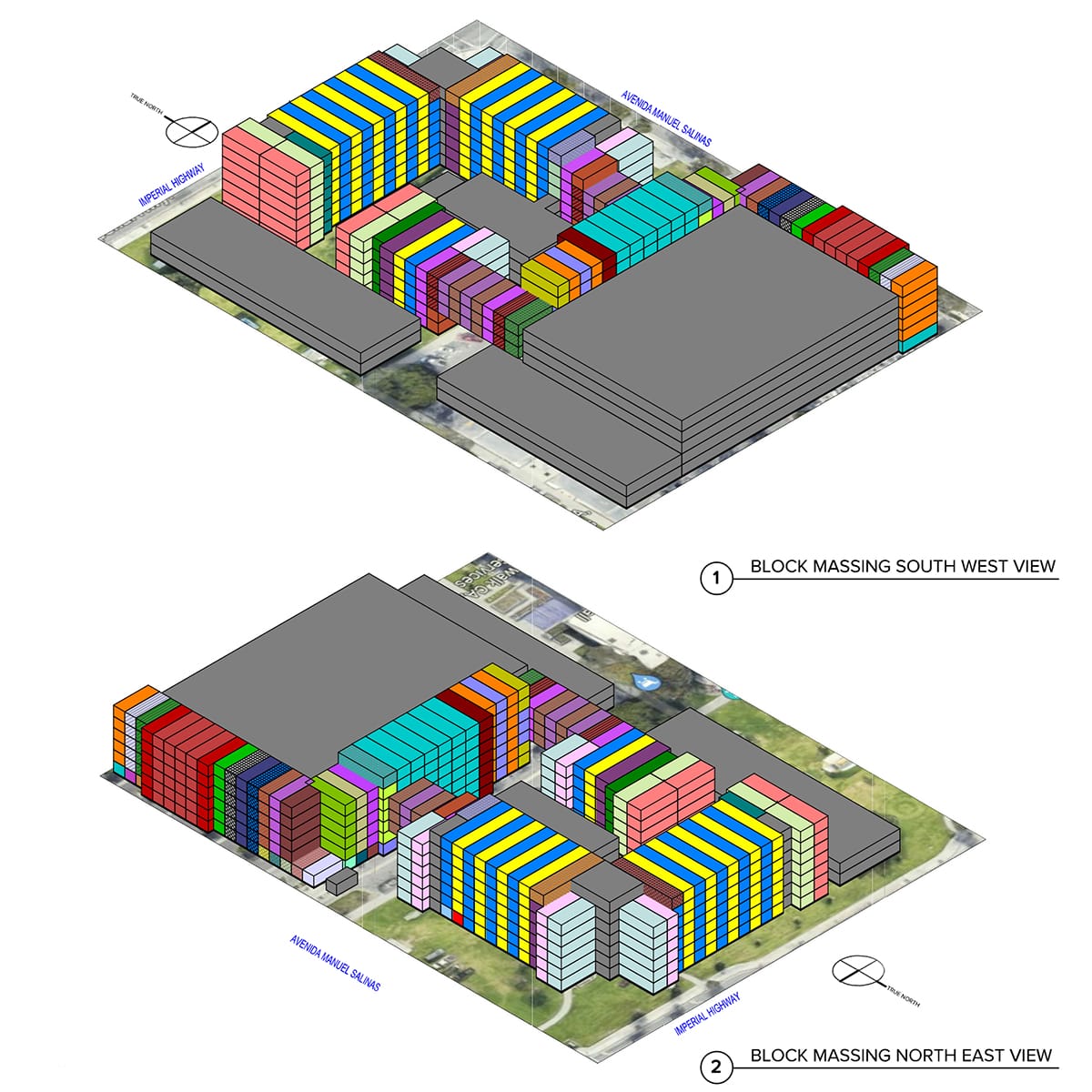

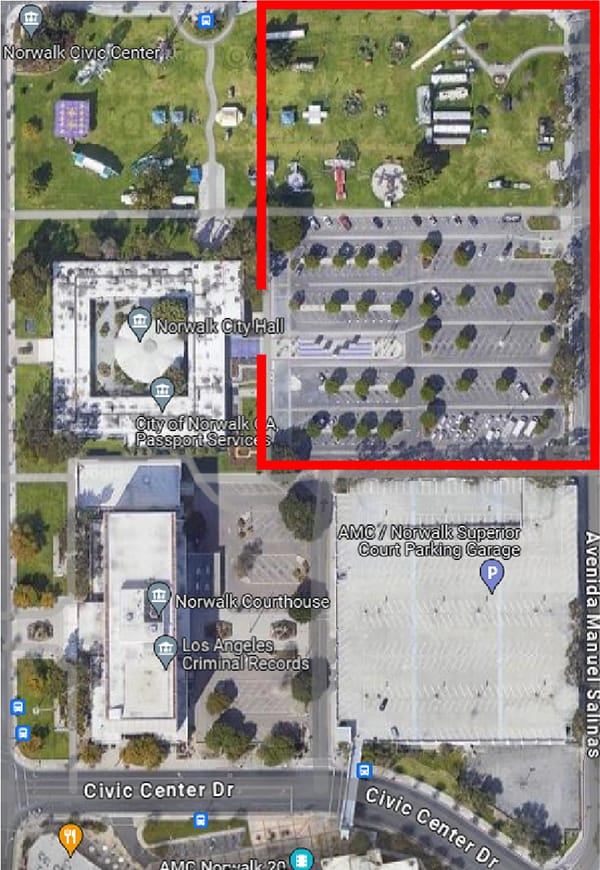

In April 2023, Primestor, a real estate owner, and developer, along with their General Contractor, approached Stack Modular to evaluate their project, named “the Walk.” This multi-family residential complex is situated in Norwalk, California, and comprises two buildings with a combined footprint of 139,150 sq. ft. The development includes 58 dedicated affordable housing units and is slated to be the largest residential modular construction project in North America to date.

The initial on-site construction pricing provided to Primestor exceeded their budget by 25%, making the project financially unfeasible. Primestor enlisted Stack to assess the original project design and explore the benefits of Stack’s modular construction approach.

Stack’s Design team conducted a comprehensive review and Modular Design Analysis (MDA) of the project. They determined that a complete redesign for modular construction was necessary and recommended engaging Assemblage-Works Inc (AWI), specifically Michael Mathews, for the modular redesign.

Stack Modular provided preliminary modular pricing, proving to be significantly more cost-effective than the initial on-site construction estimate. Additionally, they presented a detailed Scope Delineation Matrix for the original General Contractor. Despite this, the updated estimate from the original project’s General Contractor remained higher than Primestor’s target budget. Primestor then sought new competitive bids for a general contractor and selected Bernards Construction based on their modular experience and collaborative approach.

Recognizing the need for an Integrated Project Delivery (IPD) approach, Stack Modular organized a 3-day Design Charette in August 2023, fostering collaboration among AWI Architects, Primestor, and Bernards. The combined team of consultants and engineers collaborated in an open forum discussion, preserving the original design intent, and addressing factors like Unit Mix, Retail spaces, open space, and entitlement restrictions. After multiple iterations, a new concept design was finalized in June 2023.

Project Snapshot

Owner: Primestor

Type: Multi-family residential

Modules: 516

Buildings: 2

New Housing Units: 373

Floors: 7 / 5

Total Gross Area: 681,129 sq.ft.

Modular Gross Area: 356,129 sq.ft

The IPD collaborative approach resulted in an additional 20% reduction in pricing for both on-site and modular components, making the Norwalk project financially viable. Since then, all team members have been actively engaged in pre-construction efforts.

Stack Modular is set to build a full 1BR / 2 Module Unit for review by the end of May 2024. This will allow Primestor and the development team to assess the modular structure, MEP systems, and finishes, providing a valuable tool to identify any issues before Stack proceeds with full fabrication in October 2024.

The Norwalk project serves as a prime example of how Off-site Modular Construction, in collaboration with Architects, Consultants/Engineers, General Contractors (GC), and Mechanical, Electrical, Plumbing, and Fire Protection (MEP/FP) Subcontractors, can make projects financially feasible by closely working with the Owner/Developer under an Integrated Project Delivery (IPD) approach.

More from Modular Advantage

DORÇE Navigates Mountainous Terrain, Extreme Weather to Help Rebuild Türkiye

The February 6 earthquakes in 2023 were enormous. In response, DORÇE moved quickly, obtaining a government bid to help create housing and multipurpose structures—both temporary and permanent—for earthquake victims and laborers hired for reconstruction efforts.

Modern Desert Oasis: Building Reset Hotel the Modular Way

While the off-site construction part of the Reset Hotel project has been carefully controlled and with every necessity close at hand at BECC Modular’s factory in Ontario, Canada, the remote location of the project site has created additional challenges for the on site portion of the build.

Revisiting Yellowstone Canyon Village—a Groundbreaking Modular Construction Feat—Ten Years On

With such a short building period due to impending cold, it made the most sense for park developer Xanterra to pursue modular. Yellowstone’s high visitor traffic also required some odd transportation scheduling, as traffic from the West Yellowstone entrance determined the times when trucks could unload modules. Guerdon was up to the challenge.

Built for Brutal Cold, This Modular Office Building Shines

Houlton, the county seat of Aroostook County, Maine, is a small town with a population of about 6,000 residents. Situated along the border between the U.S. and Canada, what the town is most known for is bitterly cold winters. When the U.S. Border Patrol needed new office space, a modular building approach from Modular Genius offered the perfect solution.

Panel Replacement Adds Years of Life to Navy Vessel

Panel Built, Inc., recently replaced all the wall and roof panels on a two-story US Navy barge deck house that the company had originally installed 30 years ago, giving the vessel new life. Now, the commanding officer of the unit that uses the barge said the difference between the condition and appearance from when the barge left their facility to when the project was complete was beyond his expectations of what was possible.

True Modular Building Seeks to Revolutionize Housing. It’s Next Stop: MBI’s World of Modular Europe

True Modular Building (TMB) specializes in crafting attainable, eco-friendly, and comfortable build-to-rent (BTR) housing with modern designs and customizable features, ensuring that residents feel at home both today and tomorrow.

From Toronto to Suriname: A Global Modular Building Story

When I AM Gold – a Canadian gold mining operation based in Toronto, Ontario – wanted to expand its mining operations in Suriname, it knew it would also need to expand its infrastructure. More specifically, they needed to build a mechanical services compound that would allow their local crews to maintain and equipment critical to their mining operations. They also knew that it would be a challenge.

There Were a “Sea of Challenges” for this Modular, Island Development

Question: Can modular construction be used to build a series of affordable, unique housing buildings, all styled to look like they were built in 1845, on an

island that caters to the wealthy? The answer is, of course, yes, but how the

team at Signature Building Systems and KOH Architecture got there is quite a story.

America’s Construction Economy: A Race Against Time

If the economy has been able to handle higher interest rates thus far, undoubtedly it will be able to manage the lower interest rates to come. But many economists are pointing out that the Federal Reserve may already be too late to the game. While they gradually reduce interest rates, the U.S. economy could quickly decelerate, at least based on theoretical grounds if not on the most recent data releases, culminating in that long-predicted recession. Only time will tell.

Top Five Benefits of Modular Office Space

Modular office spaces are transforming how businesses think about their work environments. These innovative structures offer a mix of flexibility, efficiency, and sustainability, making them a smart choice for companies looking to gain an advantage.