Inside Boutique Modern’s Mission to Make First Homes Affordable and Efficient in The U.K.

With a view to making homes truly affordable and efficient, Managing Director Dick Shone at Boutique Modern is revolutionizing housing in southeast England, one project at a time.

Working in a 32,000 square-foot factory in Newhaven, Sussex, Boutique Modern is changing decades-old thinking about constructing houses, all through the use of modular.

The U.K.-based firm has been in business for 12 years, manufacturing houses for both private clients and local government, with a large chunk of its business coming from “affordable” and social housing.

“Before 2018 there was a lot of resistance to any kind of modern methods of construction,” said Dick. “The U.K. is very traditional in the way it builds homes. It’s been like turning an oil tanker trying to get people to think differently.”

Like the rest of the world, the U.K. is experiencing a dearth of affordable housing. In order to meet the need, Boutique Modern is targeting both social housing and what Dick calls “first homes,” or the first apartment or house after young adults move out from home.

The 21st Century Home, Built for Generations by Boutique Modern

When Dick and his firm started out, they worked on private projects as they waited for factory construction to be approved by insurers and lenders in the U.K. It took a while for factory-built modular houses to be seen as a viable solution to the housing shortage.

Regardless, Boutique Modern has set itself apart by providing low-cost, energy efficient options requested by local government and housing associations across Sussex.

The company is on a mission, says Dick, “to modernize construction. We believe that construction needs modernizing in order to bring it to the 21st century. The reason we started Boutique Modern is because we believe that factory house building is the best way that we can control quality, cost and program, and at the same time reduce carbon and waste.”

Eastbourne Terrace gardens.

According to Dick, the firm is a turnkey end-to-end provider of houses, redefining ownership of the construction process. In fact, Boutique Modern also manages their own groundworks to enable site installation of modules with ease.

“We take the main contract, we undertake all the technical design, and run the project all the way through to handing the keys over,” said Dick. “And then we look after the homes afterwards.”

As part of its offerings, Boutique Modern strives to keep everything local, sourcing 90 percent of its materials within the U.K. and suppliers within southeast England. The furthest a module has traveled is a modest 32 miles from the Newhaven factory.

“The business model is based on lower volumes than many house building factories, we require fewer homes each year to be profitable and the south east provided this volume.”

Boutique Modern also offers repairs, updates, and upkeep to all of its clients, depending on what they need. And it’s through these ongoing relationships with their clients that the company learns more about how to maintain true efficiency and sustainability in their product.

The firm stands out as the first modular construction company to obtain a B Corp certification in the United Kingdom—and the certification is core to the foundation of the company’s work.

“We’re basically providing everything that we believe housing should be,” said Dick.

Energy Efficiency in Affordable Housing Requires Education

One of Boutique Modern’s first affordable housing projects involved a three-story building featuring 13 one-bedroom and two-bedroom apartments. The block of flats, located on Fort Road in Newhaven, features floor-to-ceiling windows, mechanical ventilation with heat recovery (MVHR), and a solar photovoltaic array designed to generate 60 to 75 percent of energy for each apartment.

Each apartment is made of two types of modules, a wet and dry module and each has its own battery—an expensive technology to install back in 2020.

“This was a project which was financed by the local authority to try and create truly affordable accommodation, not only in terms of the rent charged but in its running cost as well,” said Dick.

Alongside Lewes District Council, Boutique Modern delivered the modules with the aim to lower carbon expenditure and also meet energy efficiency and fire safety requirements. In the past few years, the firm has learned a lot about the value of energy efficiency and educating clients.

“We realized that there are tenants who want to engage with energy saving practices,” he said. “We found that we can save people up to 30 percent on their energy bills through education, whereas if we target an EPC ‘A’, an energy performance assessment, it adds significant costs and doesn’t reduce the energy bills as much.”

Simply put, experience shows that education goes a lot further than engineering homes and outfitting them with expensive energy-saving technology, according to Dick.

With another project in Eastbourne, on the South coast of England, Boutique Modern built seven houses. These terraced houses featured stacked modules that were installed using a point-loaded foundation system. There were issues with site contamination that would have presented challenges for traditional construction, but not for Boutique Modern.

“Modular was favorable because of its speed and the reduction in traffic: materials in, garbage out and such,” said Dick. “And we used a helical pile foundation system, which worked very well with our build system, which has a steel ring beam in the floor cassette.”

In using these foundations and modules, they were able to avoid exposing site contamination—which would have been impossible if it was done with traditional building, says Dick.

“We simply scraped the site, levelled it, and then screwed helical piles into the ground,” he said. “Some of them went in eight meters. I think there was one that went in 15 meters, then we cut those off level, capped them with a plate, and dropped houses on top.”

This is just one example of the multiple challenges that Boutique Modern faces when it comes to constructing multifamily and affordable housing in the U.K.

Street elevation of Boutique Modern's Fort Road Newhaven flats.

The U.K.’s Evolving Regulatory and Infrastructure Requirements

Chief among these challenges are the increasing costs to maintain safety in housing, including fire safety. After the devastating Grenfell Tower fire in 2017, the United Kingdom is overhauling its fire regulations.

As a result, any building over 18 meters or about seven stories is considered to be a higher-risk building and is subject to more stringent regulations.

“It’s very difficult to build above 18 meters,” said Dick. “There are some brilliant modular companies that do it, but it’s very much a specific skill. Boutique Modern stays below four stories for that reason.”

There are also hidden costs and long delays in building houses in the U.K. such as statutory service issues like stormwater attenuation, drain connections, moving unmapped existing services on brownfield land, government red tape and extended negotiations to go through, says Dick.

“That is the kind of thing that makes a developer go, whoa, we won’t go there. This is why most developers want to work on previously undeveloped land,” said Dick.

Recent U.K. regulations dictate that developers must store stormwater on site in order to manage water runoff and avoid the overloading of existing drains. Developers must now dig into the site and install stackable storage tanks with hydro brakes. In some cases, these storage tanks can be very large and new housing developments have to carry this cost.

Even with all these regulations, Boutique Modern is keen on providing answers to the problems of not just affordable housing but making use of contaminated urban sites or brownfield land.

Boutique Modern’s Modular Solution to Social Housing is in ‘ModernHome’

After a trip to the Sekisui House factory in Tokyo, Dick found additional inspiration to solve the challenge of building homes efficiently and at a low cost. In particular, he learned about how Sekisui builds houses to cater specifically to the Japanese market and how houses typically stand for 25 years and can be disassembled to rebuild anew as generational housing needs change.

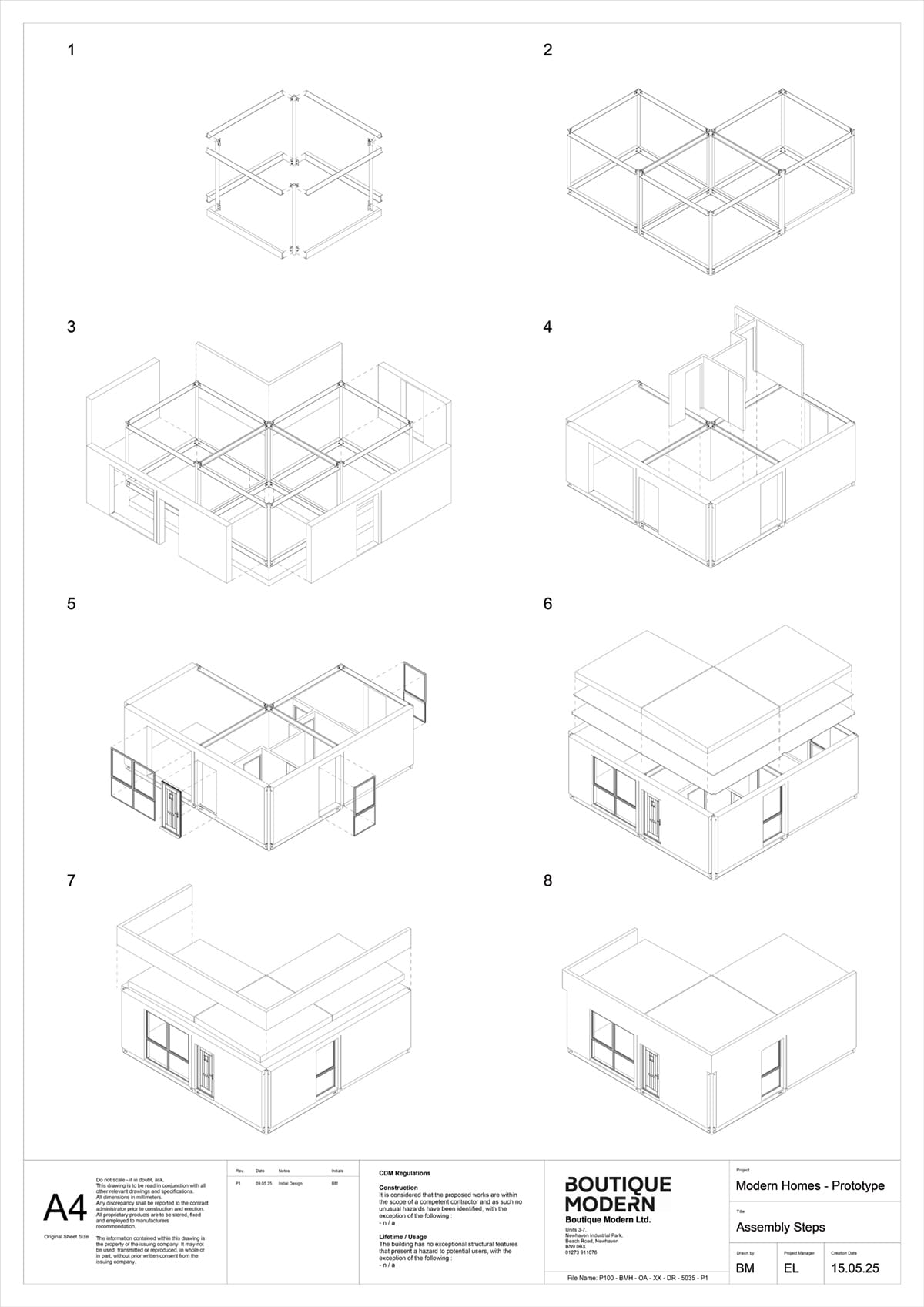

This lesson was crucial to the evolution of Boutique Modern’s newest product offering, “ModernHome.” The firm is in the process of finalizing these IKEA-esque, quick-to-install modular homes that will help address the “First Homes” need at a low cost.

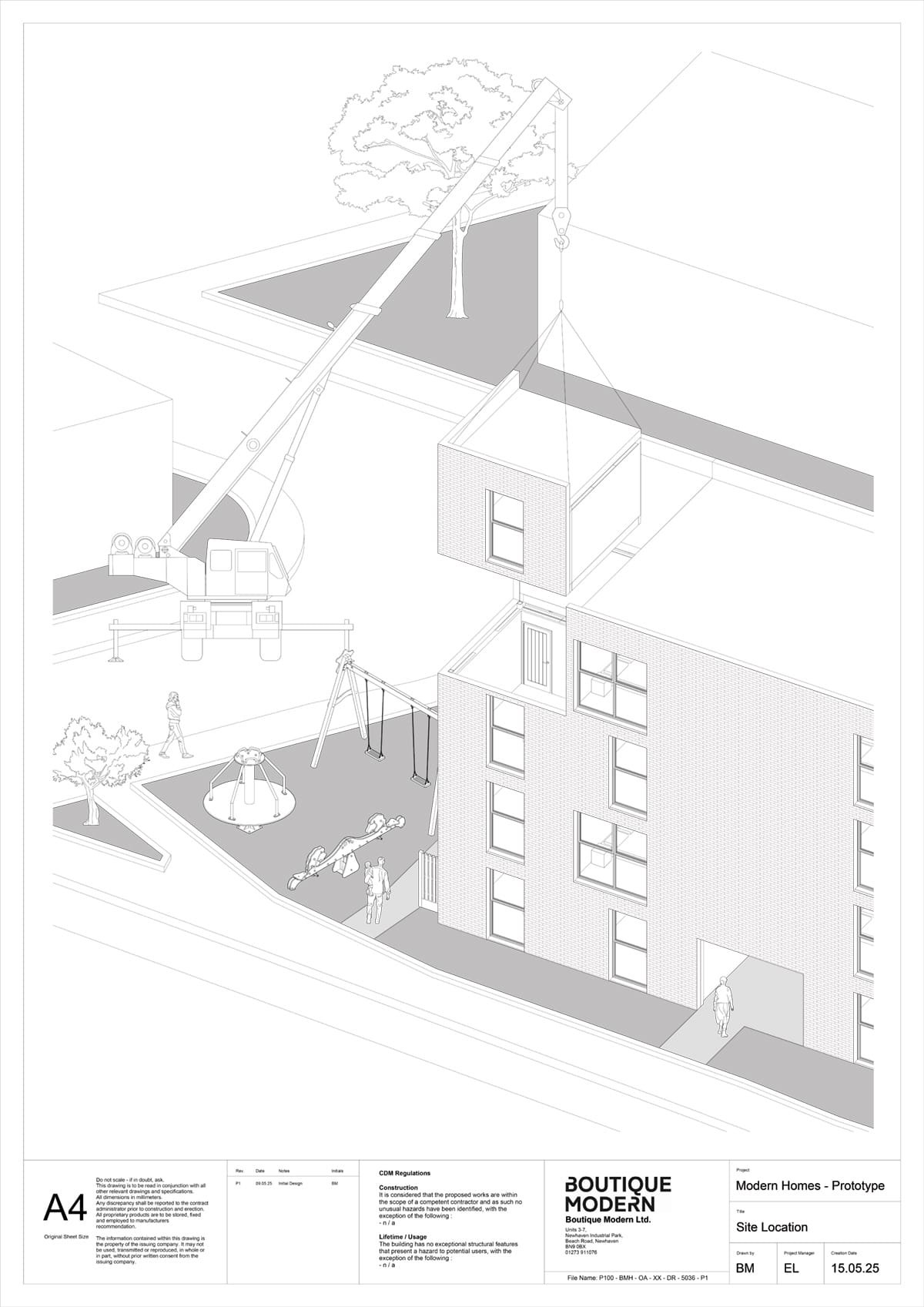

“The team looked at how we could remove waste completely, how we could speed up the construction processes, how we could refine M&E, how we could stack these boxes effectively, how we could transport them cheaply,” he said. “ModernHome uses smaller boxes, so they need smaller cranes, which means we don’t have to close roads for long and the whole process can move faster.“

In targeting the city dweller in their first rented home, Boutique Modern provides a multiprong solution to a variety of issues such as site construction on brownfield land, building on smaller sites, and provides affordable housing.

“I think a product like ModernHome, which is out of the box made in volume, and avoids multiple sticking points in the construction process, whilst being compliant with regulation, we can provide truly affordable housing in locations where people would like to live.” says Dick.

“ModernHome is safe, economical, low-carbon, circular, and it can go into places where housing is needed, and where people can work, socialize, and build a life, then it is the answer.”

Fort Road interior detail.

About the Author: Karen P. Rivera is a freelance writer and editor with a passion for storytelling. She is a former United Nations-based reporter, with experience covering international breaking news, venture capital, emerging healthcare tech, and the video game industry.

More from Modular Advantage

How Stack Modular Is Using AI to De-Risk Mid- to High-Rise Modular Construction

Artificial intelligence is no longer a future concept in modular construction—it is already reshaping how complex buildings are evaluated, designed, and delivered.

Gearing Up for the 2026 World of Modular

The Modular Building Institute (MBI) is bringing its global World of Modular (WOM) conference and tradeshow back to Las Vegas in April, and with it comes some of the industry’s best opportunities for networking, business development, and education.

New High-Rise Modular Apartment in Abu Dhabi Points Toward the Future of Multifamily Construction

Eagle Hills International Properties chose the BROAD Holon Building for a 16-story market rate apartment building in Zayed City, a central business district of Abu Dhabi. The project highlights the potential of the Holon system of volumetric modular construction to accelerate housing delivery.

MBI Announces First Ever Industry Apprenticeship Program in Collaboration with Marshall Advanced Manufacturing Center

MBI recently agreed to partner with Marshall Advanced Manufacturing Center (MAMC) to provide bona fide USDOL-approved apprenticeship programs for the industry.

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.