BoulderMOD: Producing Affordable Modular Homes While Training the Workforce of the Future

Colorado has been hit with a double whammy—a decline in the number of skilled construction workers and an increased need for affordable housing. BoulderMOD, a partnership among the city of Boulder, Flatirons Habitat for Humanity, and Boulder Valley School District, is tackling both problems and helping others do the same.

Nationwide the construction industry is beginning to see some growth in the number of skilled construction workers. But the state of Colorado isn’t enjoying that resurgence of growth. Colorado is losing skilled laborers—especially those trained in housebuilding.

According to the US Bureau of Labor Statistics, in 2024 Colorado ranked third from the bottom in state rankings for construction employment. Last April, the state was down 4,300 construction workers compared to April 2023.

The High Cost of Housing

At the same time, the price of owning a home in Colorado is well above the national norm. Motley Fool Money shows the typical home value in the US is $371,133. While in Colorado, the cost jumps to $570,492—160% of the typical U.S. price. This lack of affordable housing impacts lower-income families and first-time homeowners the most.

To increase affordable housing, the city of Boulder vowed to ensure that 15% of all homes in Boulder will be permanently affordable by 2035.

Ponderosa Community Stabilization Project

To increase affordable housing, in 2017 the City purchased Ponderosa Mobile Home Park in North Boulder, a diverse community that is susceptible to flooding. The plan was to replace outdated infrastructure, reduce flood risk for residents, introduce energy-efficient, long-time affordable housing, and reduce displacement. The goal for the Ponderosa project is to build 60 energy-efficient homes in the

community by 2035.

Boulder partnered with Flatirons Habitat for Humanity as the project’s contractor. Flatirons Habitat, which serves Boulder and Broomfield counties, built several homes onsite, but the City realized that it wouldn’t reach its goal using conventional construction methods. Like many cities and municipalities, it began looking at factory-built modular homes as a solution to help solve its affordable housing issues.

At BoulderMOD, local students get hands-on training from reading prints to building floors, walls, and ceilings.

Ponderosa Community Stabilization Project

The City had the funds, but not the expertise so it hired a modular start-up production consultant to guide them through the process. Flatirons Habitat, its partner in the Ponderosa project, is known for pursuing creative housing solutions to build affordable housing. The organization was open to the concept of modular housing. They could supply trained staff and volunteers. The volunteers would supply hands-on labor to help reduce costs.

But the City also wanted to train people to be skilled tradesmen to help it recover from its shortage of skilled construction workers in the future.

Enter Boulder Valley School District (BVSD). The school provided the property for the construction of a modular factory as well as students from its technical education programs. Students work alongside skilled tradesmen to receive hands-on experience in carpentry, electrical systems, and sustainable construction methods. They can earn educational and professional credentials, while enhancing the project’s labor force.

It’s a win-win-win—for everyone.

To build the modules, they would need a factory set up for modular construction. That was expertise the partnership didn’t have. One of the consultants recommended they talk with Daniel Sissom.

Sissom, modular factory manager at BoulderMOD, has more than 25-years of experience in the modular building industry. He started out driving a forklift and served in all aspects of the industry.

“I worked my way up—all the way up—to where I’m at now,” he said, adding that he’s set up several other modular factories from the ground up.

It was a solid partnership from the very beginning. The partners knew their idea and goals were good, and they were eager. But they were venturing into unknown territory. Having bi-weekly management meetings to answer everyone’s questions kept the project on track.

BoulderMOD – A Model of Efficiency

One thing that sets BoulderMOD apart from other offsite housing efforts nationwide is that the factory is a net-zero energy building. It uses no more energy than it generates on-site. Currently, it’s one of the only modular housing factories in the U.S. rated net-zero.

The climate-controlled factory is a model of efficiency. On the exterior, solar panels, 333 kilowatts, run along the entire roofline.

“We just got the solar panels hooked up in May, so we’re not really seeing any benefits yet,” Sissom said. “But once it’s up and running and we start full production, the solar roof will cut our overhead costs on electricity.”

Inside, BoulderMOD doesn’t use a large air compressor with airlines running throughout. Instead, it uses battery-operated power tools. This cuts costs as well as eliminating safety hazards.

BoulderMOD – A Model of Efficiency

“The skilled labor shortage is the main factor that influenced the demand for factory-built homes, Sissom said. “The second thing is the timeframe. We can build modular homes in a much shorter timeframe using less people.”

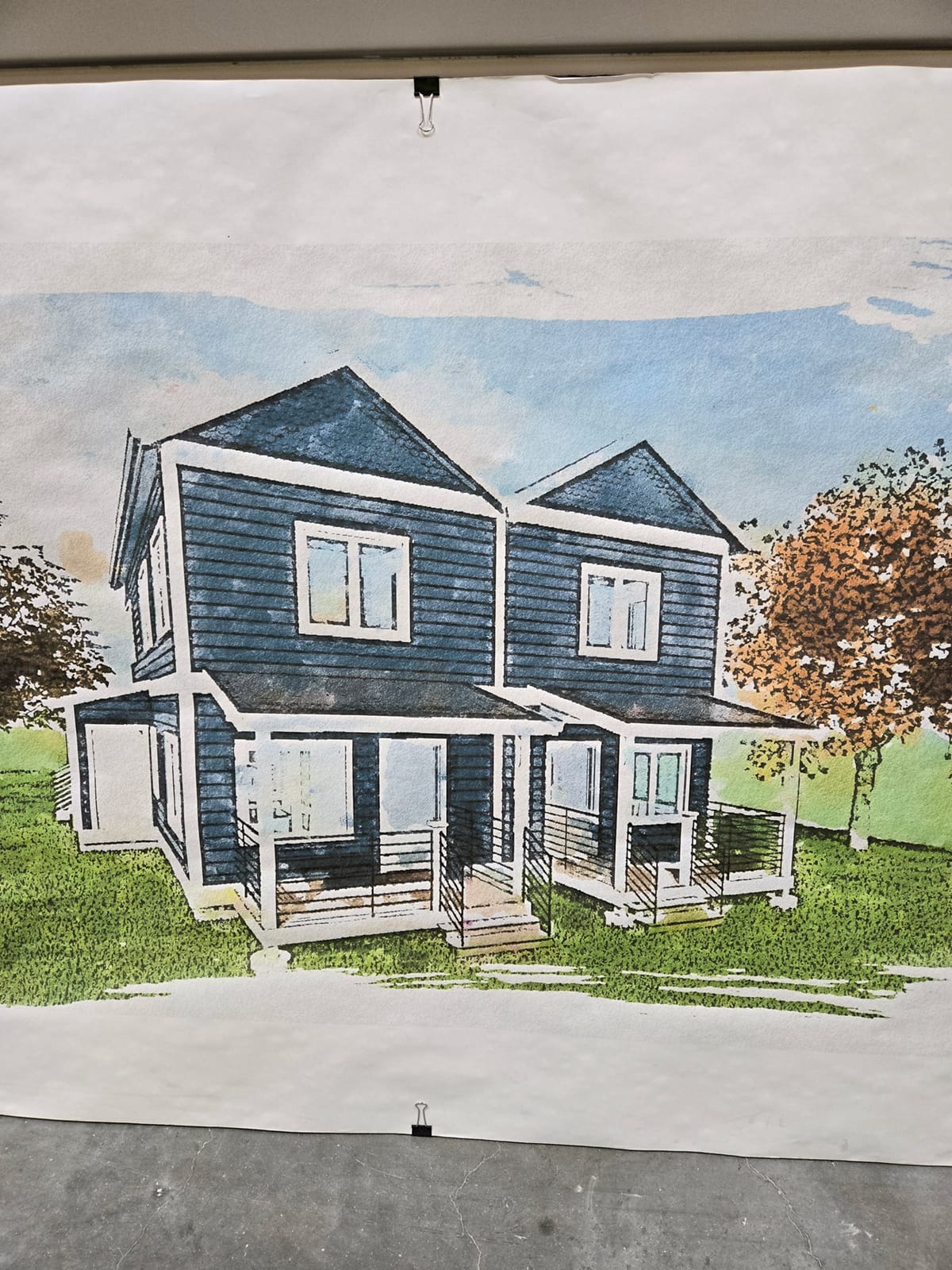

The model for the multifamily Ponderosa homes is two, two-story side-by-side homes. Each individual home is made from two modules, for a total of four modules per building.

“We started production in February 2025,” Sissom said. “I have five homes on the production line right now and we’re scheduled to set the first home on the site of the Ponderosa project on August 15th.”

Each home is an energy-efficient net-zero home. A third-party inspector comes to the factory to oversee the insulation process and tests each home.

The factory will begin operating at full capacity by the middle of August 2025. At that point the factory will be producing nearly 50 modular houses per year. Every month two houses will be set at the Ponderosa site.

“We’re a non-profit so we’re not out to mass produce homes to make a profit,” Sissom said. “We keep a low number like that so we can focus on the training aspect with the students and volunteers.”

BoulderMOD Earns Top Marks for Training

Students learn how to read architectural and structural blueprints. They receive hands-on training on tools for the construction trade and learn skills in electric, plumbing, and HVAC from subcontractors. All subcontractors must agree to train students in their particular area of expertise.

How is the training coming along? So far BoulderMOD has trained 25 students.

“Students absolutely love it,” Sissom said. “They know they’re not walking into a classroom to build a doghouse for a grade. They realize they’re building somebody’s home, and they take that personally.”

This first year, 12 juniors and nine seniors signed up. Those numbers have tripled for the next school year based on students’ word of mouth. About 40% of participating students are female.

Sissom said it’s easier to train students than those who have previously worked in construction. Students pick up the principles of modular building faster and easier. From more experienced workers, he hears “this is the way we’ve done it before” or “this is the way we do it in the field.”

“I tell them to forget everything they’ve done in the past,” he said. “This is the way we do it here.”

BoulderMOD also trains the Flatiron Habitat volunteers. There are many repeats—volunteers that come in four days per week. Some have gained enough knowledge of the process that they are “promoted” to production leads and supervisors and train new students and volunteers.

By constructing the homes with factory-built modules, homes can be built faster, at less expense and available to serve more families per year. That’s good news for families who need affordable housing. But it goes beyond the physical building.

A sketch showing tBoulderMOD's finished side-by-side modular homes.

“Although the houses are still under construction, the data shows that providing access to stable and affordable housing improves the wealth-building opportunities for the families, their health outcomes, and improved educational potential for the children,” Sissom said.

Looking Ahead

In the future, BoulderMOD will likely produce modular homes with a variety of floor plans. It has that capability.

“I see modular residential homes and commercial buildings becoming more popular as more and more people learn about modular,” Sissom said. “There’s no limit to what we can do.”

The factory is already receiving kudos. In June, BoulderMOD was awarded the prestigious Eagle Award at the 2025 Housing Colorado

annual awards event for outstanding achievements in the affordable housing industry in the state.

While that kind of recognition is nice, Sissom is just as proud of the training BoulderMOD is doing.

Currently, BoulderMOD is in discussions with other Habitat affiliates to help them recreate the model it uses. It’s also talking with other manufacturers and construction companies to take its concept of creating training programs to them.

“We are the very first of its kind training facility for modular homes,” Sissom said. “We want to spread the word and help anybody else who wants to start a training facility—other manufacturers, construction companies, subcontractors. Anybody can do what we’re doing.”

About the Author: Shari Held is an Indianapolis-based freelance writer who has been covering the construction industry for more than 20 years.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.