Developers and Designers: Lessons Learned with Modular Design

The tagline for Colorado design firm LAI Design Group is “Designers that think like developers.” It’s ideally suited to founder Ken Puncerelli’s background. “I'm not just a designer,” he said. “I see projects through the lens of a developer, if they could design.”

With over 30 years of experience in construction and design, Puncerelli has worked in the field and holds four degrees in architecture, landscape architecture, finance, and business. He started LAI in 1996, and his first foray into modular design came in 2003, when Guerdon founder Lad Dawson approached him with a workforce housing project in the mountains of Colorado.

After completing site planning for the residential development, he began to wonder why more homebuilders weren’t using modular for their projects. “It seemed like an efficient way to do repetitive production design while still achieving meaningful architecture for people to live in,” he said.

Now with over two decades of modular design experience under his belt and his business and finance background, he offers sage advice for developers and design teams, whether they’re just starting or have decades of experience.

Onsite crane placement of volumetric modules in progress. Each module arrives nearly complete—windows, drywall, fixtures, and finishes installed—allowing rapid assembly and reducing weather exposure and onsite labor.

Know When to Use Modular Construction

Not every project is suitable for modular construction, according to Puncerelli. He believes three circumstances make modular financially attractive: a remote site, a limited labor pool, and a limited construction season. When all three are present, modular pricing is often less expensive than traditional construction.

In Colorado, projects in the mountains are better suited to modular construction due to their remoteness, limited labor availability, and harsh winters. Conversely, projects in larger cities are often best served by traditional site-built construction methods. Knowing when to use each method will help developers keep costs down.

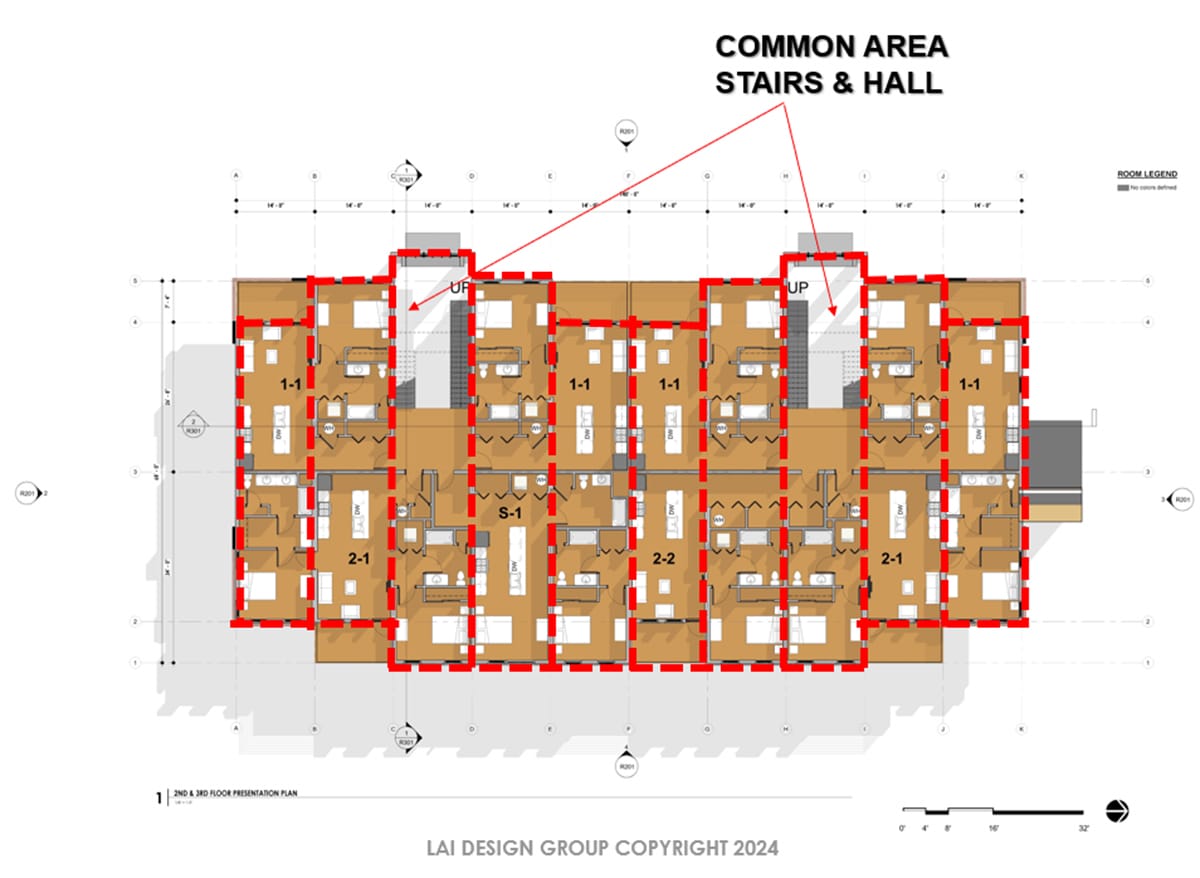

Annotated floor plans identify each modular unit and its connection points. These diagrams establish how modules stack vertically and connect horizontally around the central corridor and stair core, supporting efficient assembly and simplified MEP tie-ins once onsite.

Understand the Project Goals

All members of the project team need to understand the developer’s project goals, including operational objectives. He also recommends designing for maintenance access. For instance, locating electrical panels and plumbing shutoff valves in the hallway of a multi-family development or hotel so that maintenance personnel can more easily shut utilities off without having to enter the apartment or room.

Another key is understanding the possible financial consequences of schedule delays. In most cases, the developer will have to pay additional fees and interest on their loan if the project is delayed. Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs. Designers should be aware that developers may ask them to expedite the process, depending on the magnitude of the savings.

Use a General Contractor Who’s Familiar with Modular Construction

Choosing a general contractor who’s familiar with modular construction can make a big difference in outcomes and costs. GCs that haven’t worked with modular construction before may not know exactly what to expect and, consequently, may overestimate costs.

Puncerelli recommends selecting a contractor that understands which portions of the project's risk shift to the factory, where the units are built in a controlled environment. He also suggests choosing a contractor that you can work with and that communicates well.

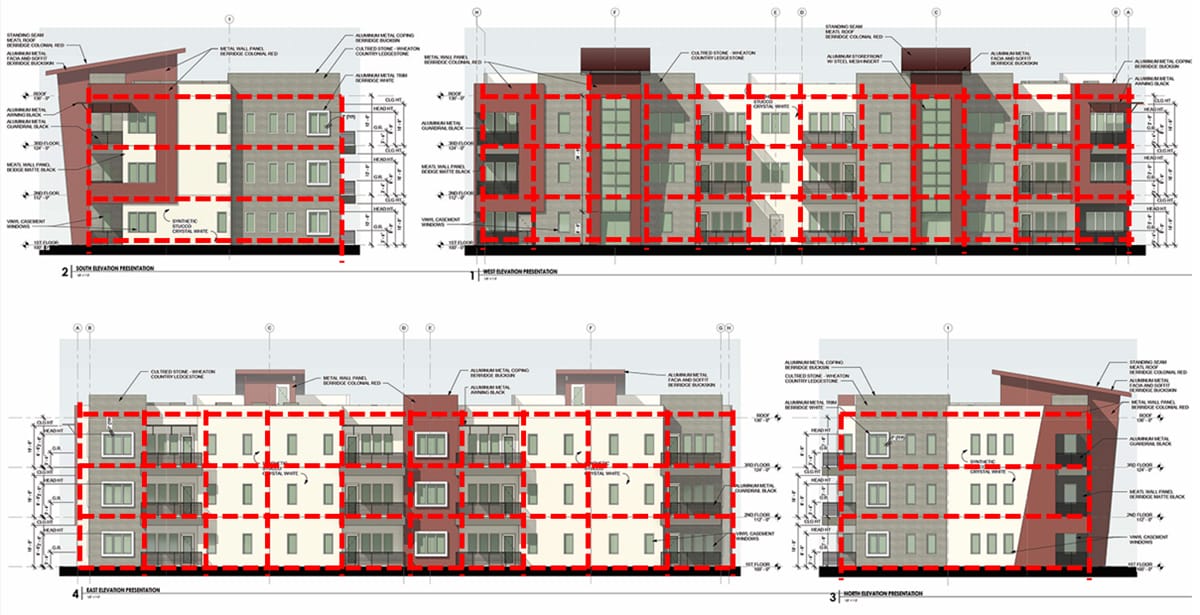

Elevation studies illustrating the modular grid that underpins the building’s structural and façade rhythm. The grid clarifies stacking logic, window alignment, and material transitions, ensuring each factory-built module integrates seamlessly into the architectural expression.

Understand the Logistics Required

Transporting modules isn’t as easy as just driving from A to B. There are many considerations when picking up, routing, and delivering modular units. Weight and height restrictions, winter weather, summer road construction, and oversize load curfews can significantly increase the cost and time required to deliver the modules from the factory to the job site. “If you don’t design with these realities in mind, the project can fail before it even leaves the drawing board.”

Puncerelli says teams must carefully select unit width, considering transportation constraints, project size, and module count. Surprisingly, smaller isn’t necessarily better. Puncerelli said most of the manufacturers he works with prefer a minimum width of 11 to 11.5 feet.

Choose the Right Manufacturer

When selecting the module manufacturer, consider their experience with the project’s building type. For example, for an apartment complex, you’ll want a manufacturer that has completed several multi-family housing projects.

When a manufacturer has experience with a particular building type, they are usually more cost-effective, Puncerelli said. A manufacturer taking on a new building type may overestimate costs to cover unknowns.

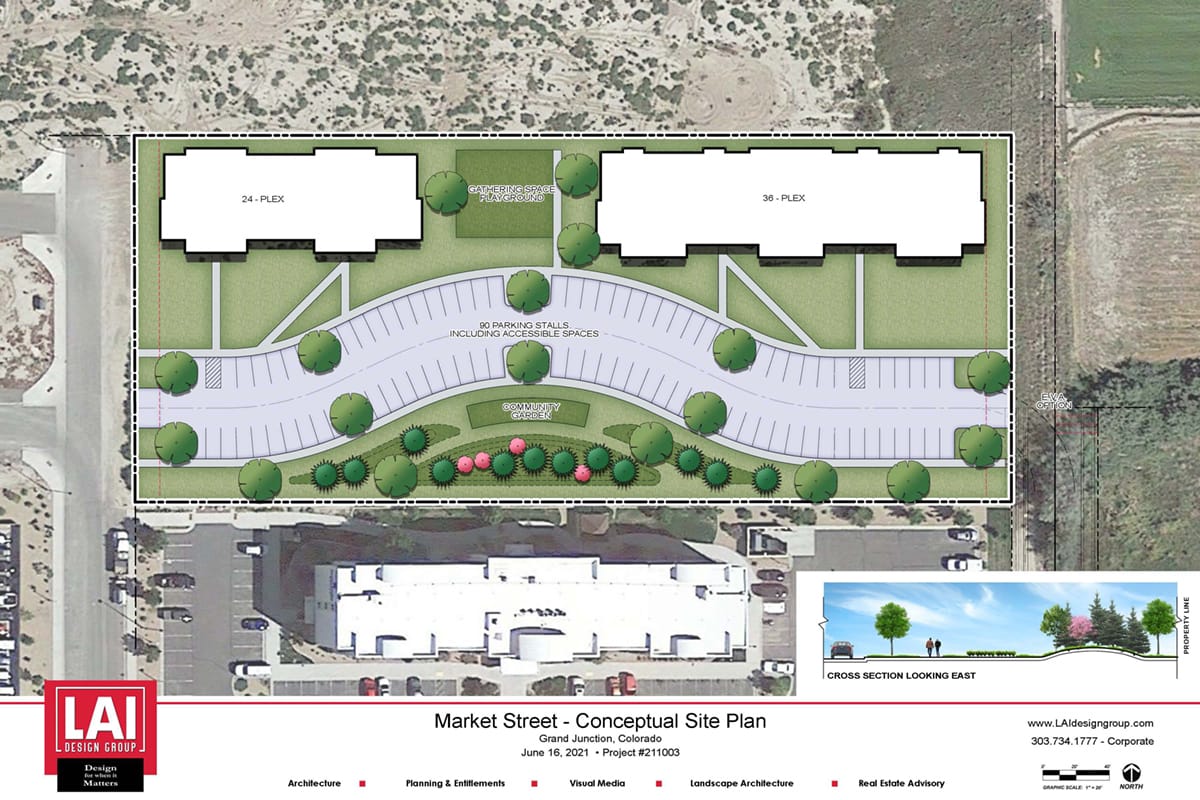

The conceptual site plan illustrates global project organization, including building footprints, circulation routes, parking, and community spaces. Early site planning accounted for modular delivery routes, crane staging, and efficient site access to support streamlined installation.

Keep the Design Team Fully Engaged throughout the Project

On a recent project in Grand Junction, Colorado, LAI was brought in to quickly adapt a site-built project to a modular approach. They completed the design but were only contacted during construction when a conflict arose. “Had we had regular meetings every two weeks or even once a month, a lot of drama would have been avoided or resolved.”

“The biggest factor for success is keeping the architect involved through construction. When we've been kept at arm's length during the build process, issues arise, regardless of whether it's modular or site-built.”

Have Regular Meetings with the Entire Project Team

Puncerelli recommends holding recurring coordination meetings to review team members' progress. “Each party brings unique knowledge to the table, whether it’s the manufacturer, architect, contractor, or engineer.”

The team must collaborate to understand what works with modular construction and what doesn’t. He recalls a project in California where his team was asked to convert two multi-family buildings from site-built to modular construction, and the design featured mirror-image floor plans for neighboring units. “While that sounds simple for a stick-built building, in a factory, that’s a whole other setup on the production line. Essentially, it’s a new floor plan. Consistency and repetition are essential for modular design.”

When asked about the future of the designer-developer relationship, Puncerelli highlighted the role of artificial intelligence. While designers are already using AI to estimate material requirements from computer models, he expects its use to grow exponentially. “I think eventually you’ll be able to tell a computer what kind of building you want, and it will create the concept and construction drawings for you. I know that sounds space age, but I don’t think we’re far from it.”

He firmly believes that developers considering modular construction should thoroughly research it and tour modular projects to ensure it aligns with their expectations. Puncerelli said it won’t work for every project, so the more they know in advance, the better their decision.

About the Author: Dawn Killough is a freelance construction writer with over 25 years of experience working with construction companies, subcontractors and general contractors. Her published work can be found at dkilloughwriter.com.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.