Five Factors to Consider When Evaluating a Modular Data Center

Kent Anderson is the Business Development Manager at Wesco.

The demand for modular data centers is on the rise as companies seek out more computing power to handle the advancements of artificial intelligence (AI), edge computing and increased security demands. But what factors need to be taken into consideration as you evaluate the next steps? Here are five elements to consider:

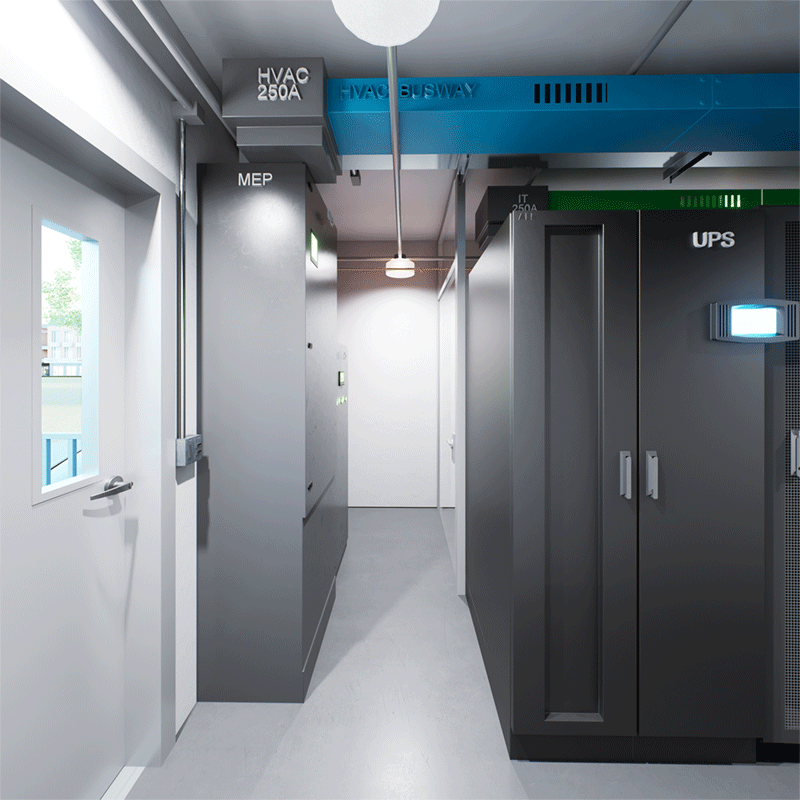

1. This is a Product, Not a Project

The beauty of a modular data center is that it can be delivered to your site and operational in mere days. That’s a big difference than building a datacenter from scratch as it eliminates customizations and complexities, reduces construction costs, simplifies the process, and perhaps most importantly saves valuable time. Traditional data centers take 12 to 24 months – or more – to build from design to construction to operation. Modular data centers on the other hand can be delivered 2 or 3 times faster, ready to plug and play. We can typically deliver a new building 3 or 4 months after an order is placed. If you want to enhance your processing power, you can simply order another modular data center and grow your system as you need it, without a capital expenditure prior to that demand.

2. When the Cloud Won’t Cut It

Given the rapid evolution of AI and edge computing, demand for computing power is high, but how quickly that computing power can impact critical business applications matters most. Data latency and data privacy are major concerns so the cloud may not be the best solution. For example, leveraging robotics in an auto manufacturing facility requires multiple complex computations to occur in quick succession. Any data latency will hinder the operation of the robot. Modular datacenters are built to handle the demands of innovations such as AI and provide much needed processing power onsite.

3. Managing Physical Space Limitations

Consider a hospital where margins are thin, and every square inch of space within the four walls of the building need to be revenue generating. Instead of giving up patient rooms to make space for a data center, an exterior modular data center can provide the computing power needed without having to sacrifice opportunity for revenue. This flexibility is helpful in an expansion phase as well. If the facility is growing, the modular data center can grow along with it. No need to shut down or move the datacenter but rather this model ensures continuous operation as the space where the processing occurs can continue uninterrupted.

4. The Need for Speed

Most organizations that are considering building capacity for a bigger and better datacenter need to get it done as quickly as possible. Waiting for customized datacenters with impossibly long lead times does not need to be the norm. With modular data centers, businesses can simplify the decision process and operationalize quickly. But trading up on timeliness doesn’t mean sacrificing quality. Rather, modular data centers are built with resiliency and redundancy in mind, including backup generators to avoid downtime.

This is also critical in remote areas where skilled labor can be a concern. Skilled labor that is familiar with setting up data centers is typically limited to larger cities. By completing the majority of the work in a factory, the skilled labor does not need to travel to various job sites. This flexibility improves schedules, reduces costs and creates a more consistent product.

5. Built for Today and Tomorrow

There is a dated misconception that modular isn’t as sturdy as onsite construction, but nothing could be further from the truth. Could your data center structure handle heading down the highway at 60mph? Modular data centers are built to the same code specifications as traditional construction process. Inspections are done at the factory, eliminating often complicated (and time consuming) onsite inspections. Plus, if plans change, the modular data center can be moved to another site or relocated back to headquarters if needed. Wherever you need computing power, you can have it. Flexibility is inherent in a modular data center.

Also, when you realize that the units are relocatable, you also can appreciate that unlike traditional construction, these units can have multiple lives in multiple locations. Traditional buildings need to be demolished when their useful life comes to an end. A modular building can be relocated or sold. By extending the lifespan of your modular data center, you are creating less waste. They even have much less waste when the units are built.

Leaning on a Trusted Partner

As the demand for data center capacity continues to grow, businesses may need to find innovative ways to meet those needs. Budget, space constraints and other considerations may make modular data centers a great option, but if you’re not familiar with them, incorporating one could seem like a daunting task.

Your distribution partner can provide the valuable expertise needed to weigh your options and determine whether a modular data center is a good fit. They can also connect you with top-tier manufacturers who can ensure you have the computing power you need, while still working within your physical limitations.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.