Tamarack Grove Engineering: Designing for the Modular Sector

From initial analysis to construction administration, the role of a structural engineer is crucial to a modular project's success. Here’s why.

In 2003, CEO Brian J. Sielaff, P.E., S.E., P. Eng., who had 12 years of structural engineering experience under his belt, worked part-time on a new venture. In 2007 he started full-time with Tamarack Grove Engineering, a structural engineering company in Boise, Idaho. He hired several employees and turned his sole attention to his fledgling company. Then the Great Recession hit.

Once again, Sielaff was the sole employee, but he persevered. In 2011, Doug Hardin, P.E., who at the time was a junior at Boise State University, majoring in civil engineering, accepted an internship at Tamarack Grove. He’s glad he did.

“Since 2011 we’ve continued to grow and have had our best year every year since,” said Hardin, who is now president of Tamarack Grove. “All of it has been organic growth.”

Tamarack Grove provided the structural engineering on this ground up children’s care facility including designing modular aspects and site build portions.

Over the past two years, the company experienced an explosion of growth. Today, it has more than 40 employees. Last fall the company opened new offices in Bozeman, Montana and Lyndhurst, New Jersey.

Hardin attributes the company’s growth to two things: One, having great clients, and two, diversification — both in the breadth of its clients and the type of work the company does.

Tamarack Grove offers structural engineering services — project analysis, plan creation, design creation, and construction administration — for commercial, manufacturing, facilities, public services, and modular. Modular is only one market sector the company serves but it is an increasingly popular one.

The company is also licensed across all 50 states, Washington D.C., the U.S. territories of Guam, Puerto Rico, the Virgin Islands and the Bahamas, as well as nine Canadian provinces.

“That’s allowed us to grow with our clients,” Hardin said. “No matter where their projects are located, we’ve been able to accommodate them.”

A Passion for Modular

Early in his career Hardin got a chance to work on a modular project. It was for a childcare center in Jackson, Wyoming, a location with a short building season.

“That’s where I started to really learn the benefits of modular construction, especially in regard to how it can really speed up the timeframe,” Hardin said. “I became intrigued by modular construction in general. You don’t have to rub shoulders long with folks in the industry to build a passion for modular.”

The Importance of Structural Engineers

Structural engineers are an important asset on any construction project, especially modular ones.

“Modular projects are a bit unique in how they are built,” Hardin said. “Having an engineer with knowledge about modular projects is the key to a successful project.”

The permitting process is one factor that differs between modular and stick construction.

Modular often requires two separate permits — one for building off-site in the factory and another for on-site construction.

How the modules will be constructed is another factor. Each factory has certain preferences for how they manufacture the modules and for the type of material used. With multi-modular projects, the individual modules need to be tied together, which also differs from stick construction.

A structural engineer experienced in modular building can take all these factors into account and avoid future issues. Their value to the project increases the earlier they are brought into the project.

Salvatore Tafuro was introduced by outgoing MBI Board Chair John Buongiorno.

For example, most modular factories use only one building material, typically wood or steel. If the structural engineer knows which company will manufacture the modules, they’ll have a good idea of the material to include in the design early on. The major difference is the type of fasteners used to connect the modules. Wood modular construction relies more on nails and staples. Steel modular construction uses more screws and welds.

In addition, stick construction uses two-by-six studs covered with OSB sheathing, while steel construction may use steel straps for bracing instead of sheathing. Fire ratings also differ according to the building material.

“If we can get involved in a project early enough, we can provide input on cost implications of the materials, as well as the benefits of each, including a fire rating or a height benefit,” Hardin said.

Not only is it important to bring in a structural engineer at the beginning of the project, but it’s also advantageous to keep the same engineer or engineers see the job through from beginning to completion. Why? Efficiency. Continuity of design. Faster completion. There’s no need for an engineer to get up to speed with the project, there’s no duplication of calculations.

“Every engineer has a different thought process on how to accomplish something,” Hardin said. “And during the transfer of information from one engineer to another, there’s the chance some information will be lost or misunderstood.”

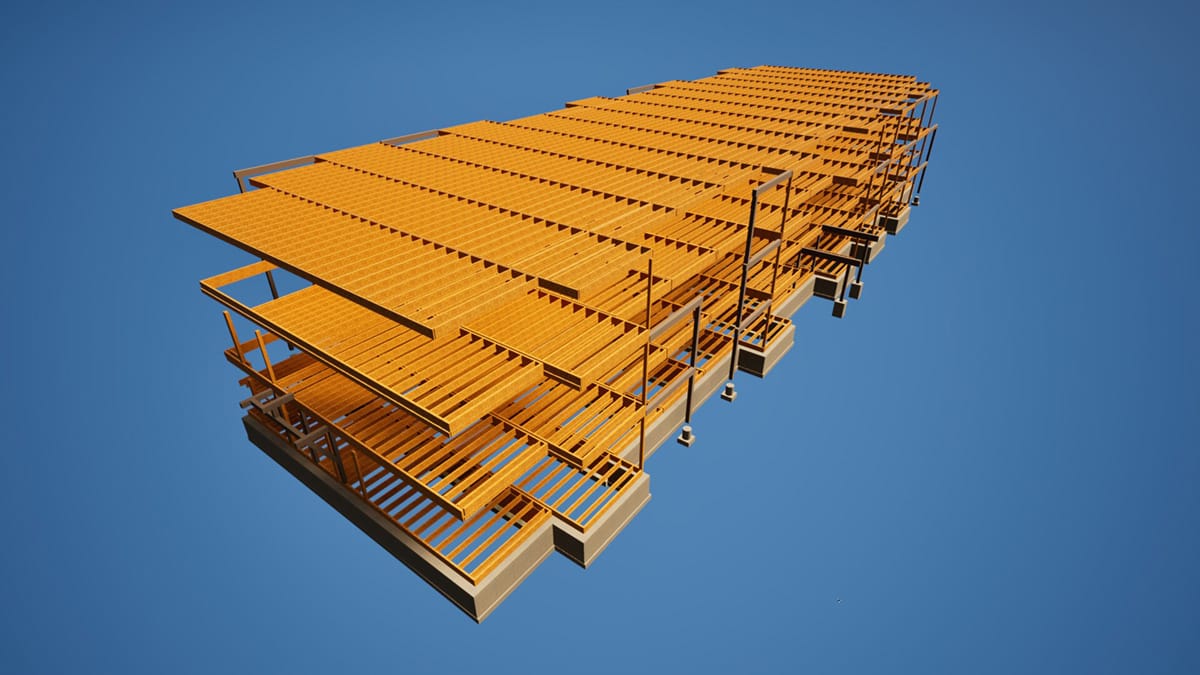

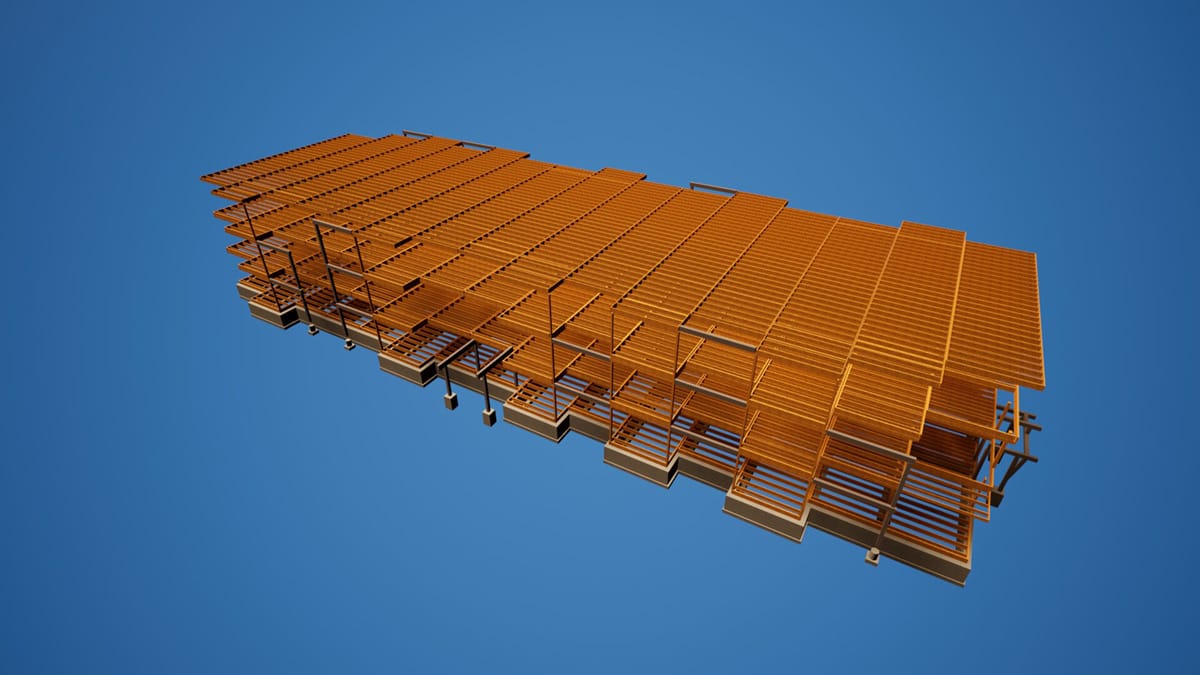

Tamarack Grove provided structural calculations for full gravity/lateral load path analysis for all shear wall, floor, and ceiling framing plans, as well as detailing for joists, beams, columns, wall framing, and associated fastener connections for 2, 3-story modular buildings.

Special Concerns

Some modular projects, like a building design in high seismic or high wind areas, call for more detailed analysis. That’s where structural engineers are an invaluable asset. Their analysis will determine what the resisting elements are.

Resisting elements for a modular design are typically the shear walls. Based on where they are located and their height, structural engineers will determine how to get the loads to the shear walls and how to connect the modules to transfer those loads across multiple modules.

For a multi-story modular structure, a structural engineer will determine how to transfer the loads floor to floor and then to the foundations.

Factory or Onsite?

Every modular project begins in the factory and is finished onsite. It’s important to determine what needs to be done where.

The foundation is the main component of onsite construction. Each location requires a foundation based on its specific soil parameters. Items that are attached to the module like awnings or decks are often created onsite as well as steps and walkways.

Sometimes shipping height restrictions is why a component such as a pitched or gable roof is attached onsite rather than being integrated in the factory.

“Everything can be manufactured and shipped at the same time as the modules,” Hardin said. “Speed of construction doesn’t have to slow just because we are adding things onsite.”

Even well-planned modular projects can experience a hiccup along the way. Hardin recalls one job that specified the sheathing and a strip of flooring be applied onsite. They created the design that way so they could strap the modules together in the field, then cover the strapping with the sheathing so the final result would be aesthetically pleasing. But the sheathing and strip of flooring were mistakenly applied to the modules prior to connecting the modules together.

“It created a quicker completion timeline onsite,” Hardin said. “But the problem was that it didn’t allow enough space for the module-to-module connections.”

The entire team — Tamarack Grove, the general contractor, the architect, and the module manufacturer — came together to find a solution. They screwed the modules together at the exposed drop beams with timber screws.

“When all was said and done, you couldn’t see them at all, and we were able to keep what they had done in the factory,” Hardin said. “It ended up being a great process overall, but it was a late in the game change.”

Collaboration is Key

Communication and collaboration are the best place to begin a modular project. Hardin’s first step is to ask questions, so everyone is on the same page.

- What is the intent of the project?

- What are we trying to accomplish?

Other questions are geared toward the preferences of the module manufacturer.

- How do you like to put the modules together?

- What standard details do you prefer to use?

- What materials will you use?

“There’s no point in creating a design that they can’t construct or that will create a hardship for them,” Hardin said. “We try to create a design that is as efficient as possible from all aspects. One of those main aspects is being able to build the module efficiently in the factory. And that’s going to vary according to manufacturer.”

Later, Hardin will discuss the constraints or limitations of the project, whether it’s the size of the modules or the ratings of a two-by-four versus a two-by-six. This will establish the design guidelines, the parameters needed to create a structural design.

Communication is critical even before the project begins. Hardin said owners, users, and financiers must understand the benefits of modular and how they apply to their project.

“Modular is the better mousetrap, but a mousetrap isn’t the solution for everything,” Hardin said. “If you’re trying to catch a rabbit you don’t use a mousetrap.”

The typical questions aimed at him involve cost of shipping versus building everything onsite and the pros and cons of different building materials.

The design team and owner also need to realize that the sooner the project team is established and begins working together, the better. The project will be more cost effective, the design will be completed quicker, the factory process will be streamlined, and the shipping process will be smoother.

“If you have everybody involved in the process early on, the issues can be addressed sooner rather than when it’s almost too late,” Hardin said.

As more structural engineers gain experience with modular construction and all stakeholders truly understand its advantages, modular construction will continue to grow. And that’s good news for everyone!

About the Author: Shari Held is an Indianapolis-based freelance writer who has been covering the construction industry for more than 20 years.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.