Building a Better World with Modern Methods of Construction (MMC)

As a global general contractor with 40+ years of experience, DORCE’s projects have run the gamut of modular and prefabricated construction.

DORCE Prefabricated Building & Construction—with production, export, and international contracting operations—is one of Turkey’s strongest brands in the global market. DORCE is also one of the first established and now-leading companies in Turkey for prefabricated modular steel structures. As a general contractor in more than 60 countries, DORCE meets all kinds of needs on a turnkey basis in different geographical regions under harsh climatic conditions at the same time with in-house engineering, procurement, production, logistics, assembly, infrastructure and superstructure works, including testing and commissioning.

In fact, DORCE owns one of the largest prefabricated steel structure production facilities in Europe, operating within the scope of local and international quality standards. In different continents and countries across the globe, DORCE has been able to realize multiple projects at the same time in different sectors including: oil & gas, mining, defense, humanitarian aid & disaster management (refugee facilities, earthquake housing units, residential projects, etc.), healthcare, construction industry, and housing.

Prefabricated Residential City for 26.000 Workers: All work for this massive workforce housing complex, including the design, engineering, infrastructure, and superstructure, was completed by DORCE. The contract model for the project on was based on a 40-year Build-Operate-Transfer (BOT) model. Construction lasted approximately four years while the superstructure was completed much more quickly—around 290 days—using DORCE’s prefabricated modular & pre-engineered steel systems.

Oil, Gas, and Renewable Energy

DORCE is involved in many turnkey energy pipeline projects ranging from camp structures, accommodation facilities, and management offices with prefabricated modular steel structures to remote, temporary camps that span thousands of kilometers along a pipeline’s route.

Mining

DORCE provides production and contracting services within the scope of turnkey construction of mining accommodation cities such as:

- Shelters, residences / accommodation facilities, and management offices;

- Hospitals and clinics;

- Markets, dry food stores, cold rooms, high-capacity kitchens, industrial dining halls & industrial laundries;

- Mining storage & processing warehouses; and

- Operational and service buildings.

DORCE has completed mining support projects in Chile, Mongolia, Australia, Canada, Africa, and Turkey.

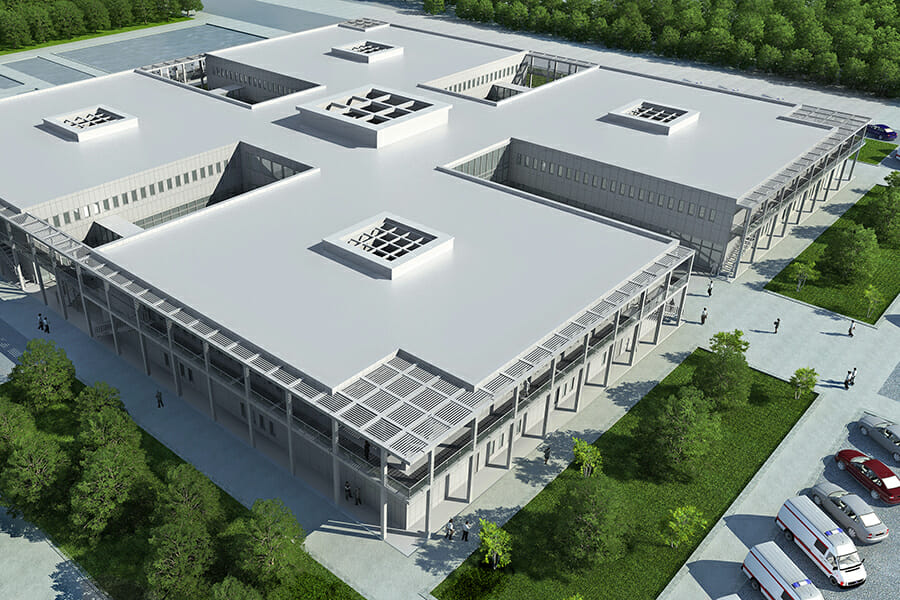

160 Bed Capacity 4 General Hospital: Utilizing Front End Engineering Design (FEED) and an Engineering, Procurement and Construction (EPC) process, the infrastructure and superstructure work for this hospital was completed by DORCE. A “hybrid building system” was utilized due to use of both light steel panels and a heavy steel structure system.

A Modular Building Fit for a King (or an Ambassador): Libyan Embassy & Administration Buildings in Ankara, Turkey, built by DORCE.

Related Listening:

Examining the Global Modular Construction Market w/ DORCE Ltd.

In this episode of Inside Modular, Mehmet Yucesoy, business development manager at Turkey's DORCE Ltd., shares DORCE's 40-year story of international success and details how modular construction can be applied to almost any construction market around the world. Mehmet also gives advice on how modular companies can begin to expand their globalization efforts.

Defense Industry

For over 35 years, DORCE has completed defense industry projects in 30+ countries, especially for NATO and NATO-member countries, the United Nations, and the Turkish Armed Forces. DORCE is a leading manufacturer of multi-purpose modular container systems such as; field (mobile) hospitals, bullet-proof facilities, turnkey military bases / camps, Air Portable Containers, education centers, and many others.

In addition, DORCE is a leading manufacturer of aircraft and helicopter hangar projects. These high-end projects—which often require prefabricated heavy steel structures—often house military helicopters, as well as F-16 & F-35 fighter jets.

Health Sector

DORCE is a manufacturer and turnkey supplier of steel prefabricated, modular, and/or mobile hospitals. During the COVID-19 pandemic, DORCE completed intensive care units, quarantine hospitals, and emergency aid facilities in 20+ countries by offering excellent flexibility and customizability on a variety of advanced hospital solutions.

Housing Sector

DORCE is also one of the preeminent companies providing prefabricated steel housing to affordable, mid-class, and luxury home buyers.

For example, more than 560,000 detached houses in California were completed with prefabricated modular building systems with evolving technology due to speed and strength of construction. DORCE took part in thousands of square meters of prefabricated housing projects in more than 20 countries with its capabilities, know-how and experience on building design, manufacturing, and construction.

In addition to the growing need for stronger houses, the volume of housing units needed—especially in urban areas—is rapidly growing. The increasing population and the emerging need for affordable housing in urban areas can be solved with Prefabricated Modular Rapid Mass Housing Projects.

With the support of its contracting services, DORCE has the capacity to quickly produce thousands of turnkey housing units. Prefabricated Modular Rapid Mass Housing is a new building trend in which production, transportation, and construction stages are all transparent, which can lead to easier access to warranties, insurance, and financing. Prefabricated Modular Rapid Mass Housing projects completed by DORCE’s off-site construction methods increase the prestige of the project owner, local community, public and private authorities with thousands of houses.

Government and Administrative Sector

DORCE completes turnkey construction of embassies as well as municipal and public buildings in more than 30 countries.

The Libyan embassy building in Ankara, Turkey, is the newest and most modern project in Turkey as of 2020. Renovation of one of the buildings was completed through rough construction. After the other structures were completely demolished, the rest of the embassy was rebuilt in accordance with modern design qualities and integrated into the remaining building.

The entire scope of the project—in accordance with the highest security measures—included bullet-proof rooms, a parking garage, conference-reception areas, meeting rooms, accommodation and office areas, as well as landscape and design services, engineering, superstructure, infrastructure, furniture, equipment, and testing and commissioning processes, and were completed on a turnkey basis.

A Building for Every Need

From humanitarian support to defense to residential, prefabricated modular steel building systems are the preferred construction method for buildings around the world. DORCE has the capability to produce large quantities of turnkey projects to suit any need.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.