PivaGroup – Specialized Windows, Doors and Panels for the Global Modular Industry

About the Author: Bostjan Jevsek, International Business Development Director, PivaGroup, currently serves on MBI's board of directors and is the co-chair of MBI's European Council.

Just 30 minutes south of Verona, a beautiful Italian city built on Roman heritage, with its world-famous amphitheater where Puccini’s and Verdi’s operas are performed in summer, lies Roncanova, quaint little village, where PivaGroup started its operations in late 1970s. When Sergio Piva founded the company, he just had but one thing in mind: to manufacture easy-to-install windows, doors, and wall panels for the modular construction industry.

Now, a couple of decades later, PivaGroup is one of the world’s largest specialized manufacturers of windows, doors, and wall panels for the modular industry.

Growth Into an industry Leader

The company is currently led by second-generation CEO Alessandro Piva. Piva reflects: “We have steadily grown but our vision is always to look ahead. Today we are present on all continents, with manufacturing plants in Europe and the USA, and we continue to work daily with our customers to develop bespoke solutions for their needs. We are a company where you not only buy a product off the shelf: we evelop and customize it for you!”

This level of interaction with customers and developing products for their needs is clearly represented by PivaGroup’s involvement in everything from supplying products to serving as a manufacturing partner, providing its customers with ready-made components of their buildings.

Claudio Piva, who leads PivaGroup’s panel division, explains: “For our modular customers, we not only manufacture wall panels, we can also install windows and doors into our walls and deliver them all ready-to-go, so they can streamline their manufacturing and assembly processes.”

International Expansion

Commitment to its international customers led PivaGroup to expand its operations to the United States six years ago and build a new manufacturing plant for PVC windows in historical Ste. Genevieve, just south of St. Louis, MO. Nunzio Sardo, managing director of PivaGroup North America, observes: “We manufacture North American window types in the US, but we are in a unique position to also offer our customers European-style tilt and turn windows and our high-end windows and doors from aluminium thermally-broken profiles.”

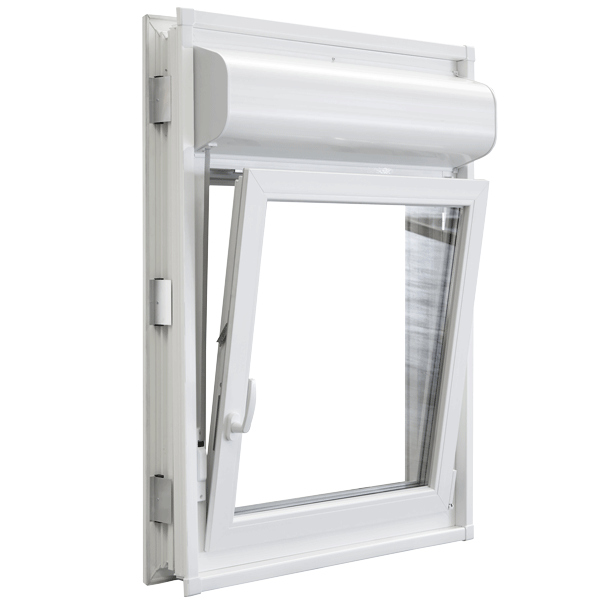

Tilt-and-turn European windows are also available in the US – with Piva Group in unique position to be one stop shop for its customers.

High-end thermally broken Al window and sliding door solutions are also available.

With ever-growing manufacturing capacity in the United States, PivaGroup is also expanding its operations around the world. Manufacturing locations in the Czech Republic, Spain, and at its headquarters in Italy, along with those in the US, mean that PivaGroup can produce more than 2,500 windows per day, more than 1,000 doors, and more than 60,000 sq.ft. of panels daily, catering to the needs for its clients worldwide.

Bostjan Jevsek, PivaGroup’s international business development director, explains: “PivaGroup is in the unique position—and probably the only windows, doors, and panels specialist supplier to the modular industry in the world—to be a truly one-stop shop for our customers. Only PivaGroup can provide specialized single pane Al windows for the Australian market, EnergyStar-rated PVC single-hungs, sliders, and casements for the North American market, and tilt-and-turn windows for the European and South American markets. We understand the challenges of different certification requirements around the world and our products comply with local regulations.

Thus, if you are an international company and have presence in different parts of the world, you do not have to look for local suppliers in each country: PivaGroup is your answer!”

A Global Perspective

Just one of specialized modular solutions at PivaGroup: thru wall AC window which supports the HVAC, but when it’s not installed can be closed.

PivaGroup’s unique modular window and door system with reveals enables 2-minute installation.

Understanding how modular construction works around the world is what drives the development of PivaGroup’s products.

For instance: Tilt-and-turn windows are not a major part of the US market, however when a large US-based multifamily developer approached PivaGroup, they presented the developer with a tilt-and-turn solution instead of the casement window. The developer loved the style, sturdiness, and high level of quality and flexibility it offered and agreed to use it in their major residential developments.

PivaGroup has been able to offer the right kind of installation process and competitive pricing. Windows will be partially manufactured in Italy and then PivaGroup North America will complete the project with single hung windows, sliding doors, and fixed windows manufactured at its US plant.

It’s this level of international collaboration that shows how PivaGroup can react to customers’ needs and think outside the box, find new solutions that exceed energy efficiency regulations, and optimize the production processes for its clients.

2-Minute Window Installation – PivaGroup makes it possible!

One of PivaGroup’s bespoke solutions is a quick-installation system for windows and doors used in the modular industry. This system was initially developed for panelized walls, but it can also work with other with all types.

To install, the window (or door) gets inserted into the opening in the wall either from the outside or from the inside and is then finished off with the counter frame (reveal), which “hugs” the wall and provides a clean looks and finish. Because windows and doors come with preinstalled gaskets, the only thing needed is to “push” both parts together.

The system can have special ragged clips, where just the pressure of both the frame and counter frame holds the window in place. For extra security the windows can be screwed into the studs through the side of the frame. This installation is completely invisible, so windows and doors always look sleek and nice in the walls. It is literally a 2-minute job!

Innovative Ideas

PivaGroup has developed other unique solutions, such as integrated operable screens into our windows and integrated rolling shutter blind systems. Rolling shutters provide added security and serve as blackout blinds.

Just recently, PivaGroup developed a certified Passive House window system with integrated rolling shutters, intended for the modular industry. This system—the world’s first—shows how forward-thinking PivaGroup’s development is, combining class-leading energy efficiency with specialized solutions for modular industry.

It is not all about the modular industry at PivaGroup. Though. There are high-end vinyl residential windows available, as well as super-sleek thermally-broken aluminum windows and sliding doors. If you fancy 15-foot-high glass sliding doors, PivaGroup has that too.

A Trusted Partner

Times are challenging in the window, door, and panel industry, of course, just like in other construction industries. Raw material prices are rapidly rising and supply is unreliable. Therefore, having established partners, such as PivaGroup, is especially important.

Alessandro Piva concludes: “At PivaGroup, it’s all about partnerships. We have customers – friends, which have been with us for decades already, because they know they can rely on us to provide the newest products, to invest in new research and manufacturing capabilities, and to be able to support their continuous growth. That’s in our DNA: We are all about long term partnerships, not quick wins.

And when PivaGroup closes for its summer break, there is nothing better than settling on a 1500-year old stone bench at Verona’s amphitheater and watch Verdi’s Aida being performed under the summer stars. Well, taking our customers to Cardinal’s game at the St. Louis ballpark comes close, but not quite…”

We will be happy to hear from you at: bostjan.jevsek@pivagroupspa.com and you can always visit our websites: www.pivagroupspa.com and www.pivawindowsna.com

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.