RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns. “When transportation and logistics aren’t considered early,” says Jeff Bobbitt, Modular Projects Manager at RoadMasters, a Division of Bennett Truck Transport, LLC, “the chain breaks and project momentum is lost. Bringing the hauler into the conversation from day one prevents routing surprises and keeps everything flowing.”

A 47-Year Legacy in Oversized Modular Hauling

Founded in 1978 as Manufactured Mobile Home Transport, Inc., RoadMasters initially focused on manufactured homes. As the industry evolved into commercial buildings, medical clinics, hospitals, and workforce housing, the operation rebranded in 1992 to RoadMasters Transport Company. In 2019, Bennett Truck Transport acquired RoadMasters, fueling continued expansion.

What began with double-wide homes has grown into transporting modules for buildings up to seven stories tall. “Modular isn’t a niche anymore,” Bobbitt notes. “It’s mainstream—especially in dense urban areas where speed and minimal site disruption are critical.”

Today, RoadMasters operates more than 95 trucks and experienced operators, including over 20 modular trailers customized for off-frame modular buildings. The fleet routinely manages two to three major projects simultaneously or up to five smaller ones, delivering nationwide.

Early Involvement Saves Time and Money

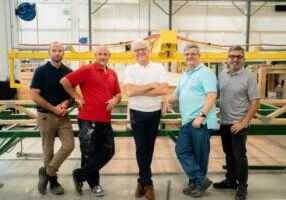

Both Bobbitt and Teena Peaslee, Terminal Manager in Meridian, Idaho, emphasize that transportation planning must start at the design table.

“If the factory says they can build a module 16 ft wide by 80 ft long, that doesn’t mean it can reach the job site,” Peaslee explains. Larger dimensions can trigger police escorts, lengthy detours, nighttime-only travel windows, or—in extreme cases—impossibility. Bobbitt cites an eastern Idaho project where shipping dimensions required police escorts, pilot cars, and routing that increased the mileage, inflating transport costs by 300%. Earlier input from RoadMasters could have optimized the dimensions as related to the permitting requirements and ultimately the transportation costs, likely cutting the expense by 75%.

Common pitfalls include:

- Constructing the module at a shipping width that requires additional distance and pilot car costs

- Underestimating height restrictions (trees, power lines, bridges)

- Not taking into account weight limits on bridges and roads

- Overlooking rush-hour and holiday curfews—some urban areas ban oversize loads for three hours or more, or restrict travel to 2 a.m.–4 a.m. windows

- Failing to verify site access, ground conditions, and grade

Peaslee recalls a delivery where a three-foot dip in the lay-down yard nearly caused the trailer to contact the module during unloading. “We need 14–16 ft width clearance and up to 110 ft overall length, plus 60 ft of swing room to exit after positioning,” she says.

Technology and Depth of Resources

RoadMasters equips its trucks with real-time GPS, dash cameras, and advanced diagnostics. Dispatch stays in contact with drivers three to four times daily. “If something breaks, we adapt and overcome,” Bobbitt says. “We have the equipment and experienced personnel to keep the project moving.”

Advice to Developers and Manufacturers

Bobbitt and Peaslee offer the same core recommendation: involve your specialized hauler early and listen.

“Developers know how to build. We know how to move it from point A to point B, considering oversize constraints,” Bobbitt says. Provide origin and destination addresses, preliminary dimensions, and a realistic schedule as soon as possible. Experienced haulers can flag dimension or route issues before steel is cut, preventing expensive redesigns or delays.

Permitting alone can take days or weeks in some states. Route surveys, escort arrangements, and seasonal considerations (winter storms, summer road construction) all benefit from long lead times.

The Bottom Line

As modular construction accelerates—driven by labor shortages, speed-to-market demands, and urban infill projects—transportation expertise is no longer optional. Companies like RoadMasters, with nearly half a century of oversize modular experience, custom equipment, and nationwide reach, have become indispensable partners.

In an industry where every day on site costs money, the real “missing link” isn’t the truck—it’s the early phone call to the people who know how to get the module there on time and on budget.

About the Author: Dawn Killough is a freelance construction writer with over 25 years of experience working with construction companies, subcontractors and general contractors. Her published work can be found at dkilloughwriter.com.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.