Accelerating Light-Gauge Steel Construction: A Semi-Automated Digital Workflow for Off-Site Projects

Amir Mehdipoor, Ph.D. is Team Leader, Industrialized and Digitized Construction, at National Research Council Canada.

Ivanka Iordanova, Ph.D. is Ivanka Iordanova, Ph.D. is a professor in the Department of Construction Engineering, École de technologie supérieure.

Introduction

The construction industry faces a persistent challenge: how to deliver high-quality buildings faster, more accurately, and at a lower cost. Off-site construction (OSC) has long promised these benefits by shifting work into controlled factory settings, where efficiency and safety can be optimized. Within this landscape, light-gauge steel (LGS) has emerged as one of the most promising materials for modular and prefabricated construction. Its strength, adaptability, and consistency make it well suited for repetitive production processes.

Yet despite these advantages, many companies that adopt OSC still struggle to unlock its full potential. This is because too often, off-site factories reproduce traditional manual workflows rather than rethinking processes around digital tools and automation. The result is that productivity gains fall short of expectations.

This industry article is based on our original peer-reviewed study “Enhancing the Manufacturing Process in Light-Gauge Steel Off-Site Construction Using Semiautomation” published in the Journal of Construction Engineering and Management (ASCE, 2025), co-authored with Ivanka Iordanova and Mohamed Al-Hussein. The goal here is to translate our research into a professional industry context, walking readers through the methodology, summarizing the findings, and highlighting key takeaways that practitioners in the LGS sector can apply directly to their projects.

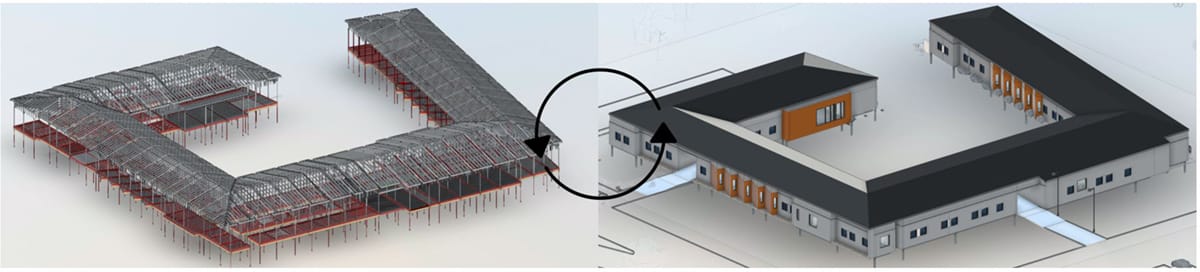

Automated Structural Framing Derived from Architectural Model

Methodology

The study followed the Design Science Research (DSR) method, a structured approach for creating and testing practical solutions in complex environments.

- Problem Identification

The researchers identified three critical inefficiencies in current LGS off-site construction:- Long task durations in manufacturing and assembly.

- Inaccurate Bills of Quantities (BoQs) due to reliance on manual takeoffs.

- Poor coordination between design, production, and assembly teams.

- Solution Design

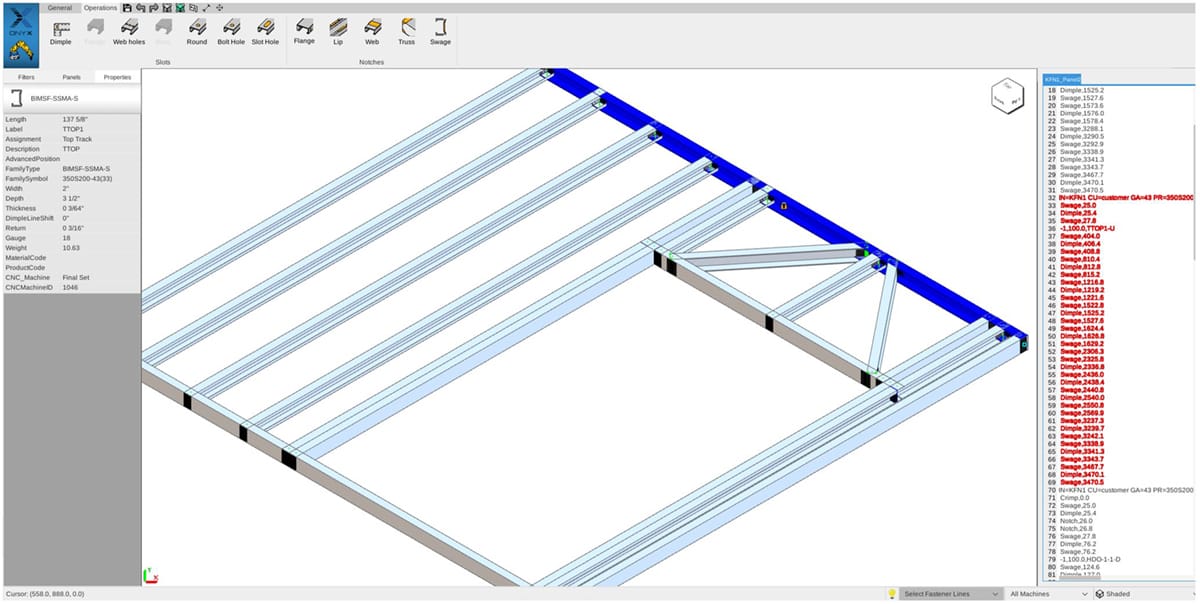

A semi-automated workflow was developed, combining:- BIM-driven design automation to generate precise models.

- CNC code generation from BIM models to control automated framing machines.

- QR-coded shop drawings allowing assembly teams to instantly access 3D BIM models for guidance.

- A Common Data Environment (CDE) for sharing design files, CNC codes, and updated documents.

CNC-Ready Light Gauge Steel (LGS) Panel Design

Unlike a fully automated approach, this workflow kept human workers engaged for tasks like feeding steel rolls, stacking studs, and assembling panels, balancing automation with flexibility.

- Validation and Assessment

The workflow was tested on a 2,500 m² modular project with 47 modules. Its effectiveness was measured by comparing:- Task durations before and after implementation.

- Accuracy of BoQs from manual versus automated methods.

- Economic feasibility, through a cost–benefit analysis calculating payback time for the required investment.

Findings

The results show that even partial automation, when well-integrated with digital tools, can transform the efficiency of LGS off-site projects.

- Major Reductions in Task Duration

- Average overall reduction: 38.11%.

- Window installation: 58% faster.

- Door installation: 67% faster.

- Roof construction: 50% faster.

- Floor frames and ceilings: up to 30% faster.

Automated CNC-driven fabrication ensured precise cuts and dimensions, which in turn made assembly smoother and quicker.

- Significant Improvements in Quantity Accuracy

- Average improvement: 10.77%.

- For certain components, accuracy improved by as much as 45%.

Manual takeoffs were shown to be highly error-prone, while BIM-based automated takeoffs provided reliable and consistent results.

- Strong Economic Case

-

- Payback period: 10 months and 26 days.

- Savings:

- Labor savings from faster tasks (38% reduction in hours).

- Material savings from more accurate BoQs (11% reduction in cost per area).

This proves that even a large upfront investment in automation, software, and training can pay for itself in less than a year.

- Improved Coordination

The use of a Common Data Environment was a standout factor in project success. Teams could work from one shared source of truth. QR codes embedded in shop drawings allowed workers to scan and view 3D models instantly, reducing miscommunication and ensuring alignment across design, manufacturing, and assembly phases.

Precision Manufacturing of Modular Building Units

Key Takeaways for Industry Professionals

The findings from this study don’t just live in research journals, they have direct, actionable lessons for professionals working in light-gauge steel and off-site construction.

BIM as a Production Backbone

Many firms use BIM primarily for visualization and coordination. This project demonstrates its deeper value as the backbone of production. When BIM models generate CNC codes for machines and shop drawings for crews, the entire workflow becomes more connected and reliable. This reduces rework, shortens timelines, and creates a direct link between design intent and production reality.

Semi-Automation Balances Cost and Flexibility

Fully automated factories may be out of reach for most companies, especially smaller and mid-sized firms. A semi-automated approach, where machines handle repetitive precision tasks while humans oversee flexible, adaptive tasks, offers a practical balance of cost, control, and scalability. This hybrid model delivers measurable efficiency gains without the need for a fully robotic factory.

Accuracy Drives Better Outcomes Than Speed Alone

Time savings are always attractive, but improved accuracy in quantity takeoffs may deliver even greater long-term benefits. Accurate BoQs mean fewer procurement errors, less material waste, and more reliable budgets. This reduces risks of cost overruns and schedule delays. For contractors and developers, accuracy is just as valuable as speed.

Standardization Unlocks Efficiency

Light-gauge steel components are inherently modular, which makes them ideal for prefabrication. But to fully benefit, companies must embrace standardized designs and repeatable processes. The more uniform and modular the components, the easier it becomes to apply digital automation. Firms that invest in standardization can expect faster returns on digital workflows.

Collaboration Requires Digital Infrastructure

One of the most underrated findings is the value of the Common Data Environment. By centralizing models, CNC codes, and documents, it created a single source of truth across disciplines. Features like embedded QR codes bridged the gap between office and shop floor, making digital collaboration tangible for field workers. Without this shared platform, even the best digital tools risk creating silos.

Training and Culture Are Essential for Success

Introducing semi-automation is not just about machines and software, it’s about people. In the case study, extensive training sessions and workshops ensured workers were comfortable using new tools. For success in the real world, companies need to invest in their workforce, build confidence in digital tools, and foster a culture that embraces change rather than resisting it.

The Business Case is Strong, Use It to Win Support

Many firms hesitate to invest in automation because of the high upfront cost. This research provides hard evidence that the investment can pay back in under a year. For decision-makers and stakeholders, this makes a compelling business case: digitalization and semi-automation aren’t just operational improvements, they’re strategic investments in competitiveness.

Start Small, Scale Smart

One practical lesson from the case study is the value of piloting. By testing the workflow on a specific modular project, the team could measure results, build confidence, and refine processes before scaling up. Industry professionals should consider starting with a pilot project that’s manageable in size but representative enough to provide useful insights.

Semi-Automated Production of LGS Modules in Factory Setting

Conclusion

Light-gauge steel off-site construction has always held promise, but too often that promise has gone unrealized because traditional workflows persist in new environments. This research demonstrates a way forward: a semi-automated digital workflow that bridges the gap between design and production, balancing automation with human expertise.

The results are undeniable:

- 38% faster production and assembly.

- 11% more accurate BoQs.

- Investment payback in less than 11 months.

For construction professionals, the message is clear. By adopting semi-automation and digitalization, companies can deliver projects faster, more accurately, and more profitably, while also building stronger collaboration across teams. The approach is not about replacing people with machines, but about empowering people with better tools and processes.

In a competitive industry where time, accuracy, and cost are everything, workflows like this could define the future of light-gauge steel construction.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.