From Volume to Velocity: Scaling Multi-Family Projects Without Losing Control

How modular builders can meet rising demand without sacrificing flow, quality, or profitability.

Daniel Small is the Founder & CEO at Da Vinci Consulting

Introduction: The Scaling Trap

All around the world, the need for modular multi-family housing is growing fast. Cities, developers, and nonprofits are turning to modular to solve housing shortages. But as factories try to build more units quickly, they often learn a hard lesson: more volume doesn’t always mean more profit.

When projects grow too fast without the right systems, factories run into problems. They miss deadlines, crews burn out, and quality drops. Instead of steady progress, chaos takes over. Things slow down, even with more units going through. That’s because building more isn’t enough—you also need to build smarter. That means shifting focus from volume to velocity.

The Volume–Velocity Disconnect

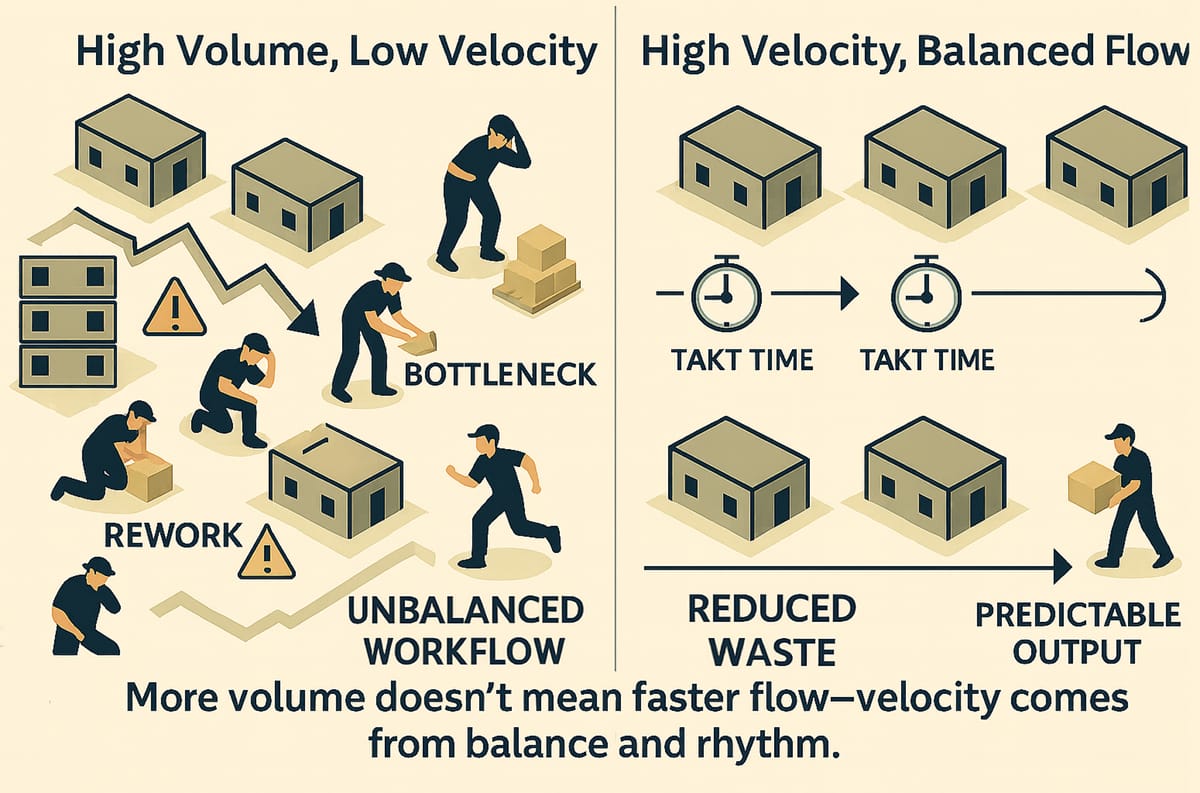

Volume means how many modules you build. Velocity means how fast and smoothly they move through the factory and into the field—on time, on budget, and with good quality. Many teams think that more volume equals more output. But if your flow is broken, more volume just creates more problems.

Imagine a factory that doubles its weekly goal from 10 to 20 modules. If the stations aren’t balanced and the process isn’t stable, the result will be delays, overtime, rework, and piles of inventory. The factory doesn’t get faster—it just gets messier.

Velocity is what makes growth sustainable. It tells you whether your process can keep up with demand without breaking. It’s not just about how much you build—it’s how well you build it, every time.

Lean Flow as the Foundation for Scaling

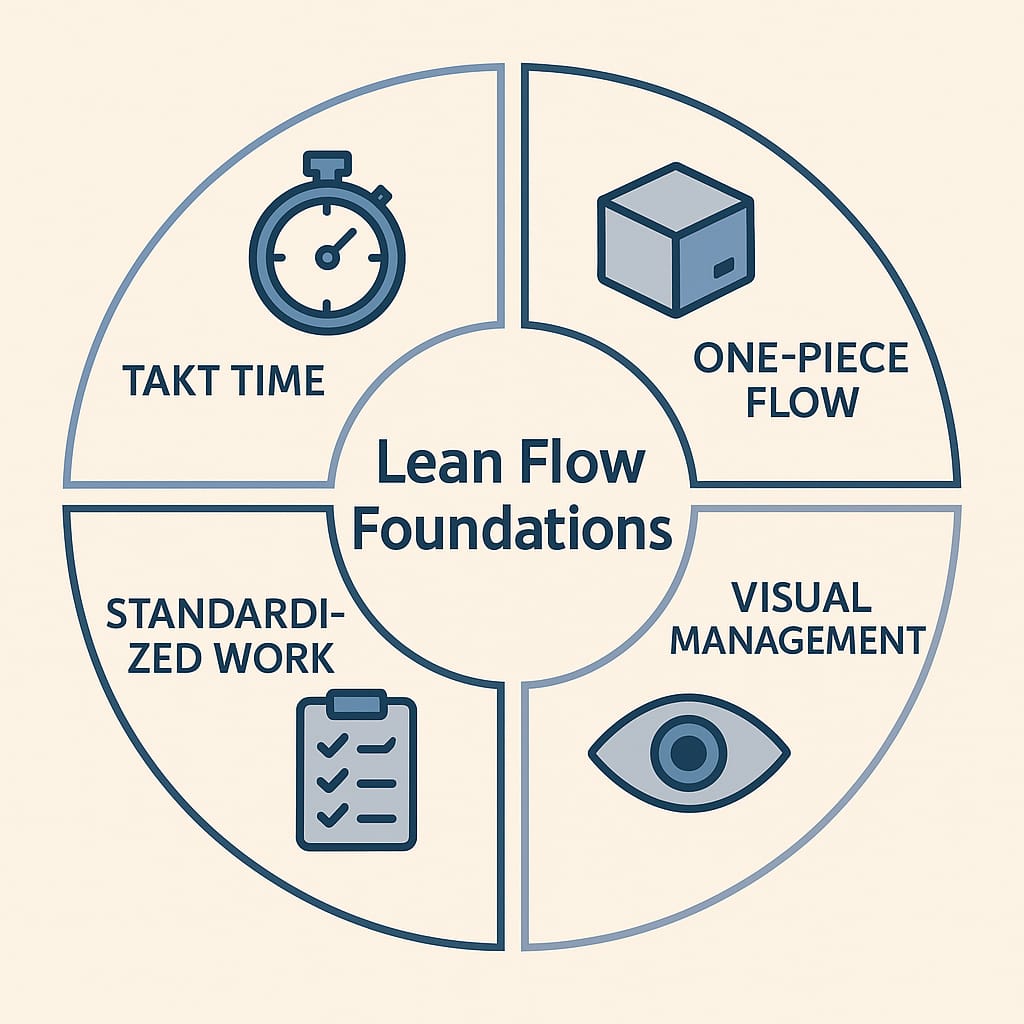

To grow without chaos, you have to build the right system first. That starts with Lean principles:

- Takt time: Set a steady rhythm that matches demand.

- One-piece or small-batch flow: Keep work moving without piles of unfinished parts.

- Standardized work: Make sure each task is done the same way, every time.

- Visual management: Use simple tools to spot problems quickly.

Lean thinking creates flow. It helps you grow in a way that’s stable and repeatable. If you try to scale without flow, you’ll be fighting fires every day. If you build flow first, scaling becomes much easier.

Systems to Stabilize Multi-Family Production

Multi-family modules are more complex than single-family units. They have more electrical, plumbing, and layout challenges. That means your process has to be even more reliable.

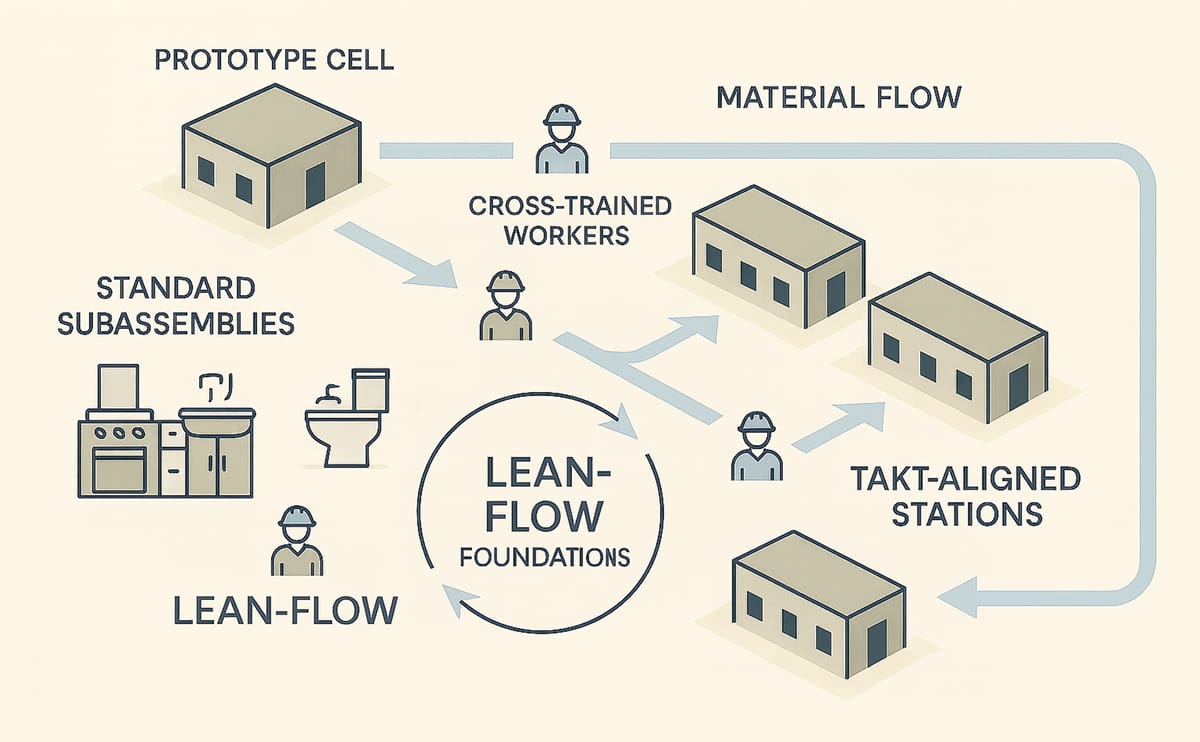

Here are smart ways to make your system ready for growth:

- Takt-based planning: Break work into chunks that match your production rhythm.

- Separate prototypes: Don’t test new designs on the main line—use a side cell.

- Standardize subassemblies: Build repeatable kitchens, bathrooms, and wall sections.

- Repeat core templates: Even in custom buildings, reuse the same module structures.

- Cross-train crews: Let team members work across stations to keep flow moving.

Also watch your labor and equipment balance. As you grow, new bottlenecks will appear. Track them daily and adjust before they slow you down. When production is steady and balanced, you can grow without stress.

Data-Driven Control During Scale-Up

You can’t manage what you can’t see. As your projects grow, you need data to stay on track.

Watch these key signals:

- Takt time tracking: Are tasks finishing on schedule?

- Inventory buildup: Are unfinished modules piling up?

- First-time quality: Are mistakes getting fixed early—or passed downstream?

- Throughput variation: Are you hitting your daily targets?

Dashboards, boards, and real-time tools help your team see what’s working—and what’s not. When workers can spot and fix problems right away, they become owners of the process, not just task-doers.

Scaling Without Losing the Client

If your factory is in chaos, your clients will feel it. Missed deadlines and sloppy communication hurt trust. As you grow, your coordination with clients and field teams must improve too.

To keep clients happy:

- Lock in designs early.

- Align deliveries with field and crane readiness.

- Set clear checkpoints for design, buying, and production.

- Communicate fast when delays come up.

One factory kept a 300-unit project on track by using a pull schedule. They only released modules when the site was ready. That simple move kept everyone aligned and avoided a huge backlog.

Your factory and field should run as one team. Without that link, even the best factory process can’t fix site problems.

Conclusion: Start Small, Scale Smart

In modular construction, success isn’t just how many modules you build. It’s how consistently you deliver—on time, on budget, and with pride in the product.

Before you ramp up, ask: Are we flowing well right now? If not, don’t scale yet. Fix the flow first. Because scaling a broken process just makes a bigger mess.

The secret to modular growth isn’t speed—it’s stability. If you build steady flow now, you’ll be ready to grow fast later. That’s how you scale smart, keep your teams strong, and earn your clients’ trust.

Real growth isn’t just bigger. It’s better, faster, and smoother. And it all starts with flow.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.