How LAMOD is Using Modular to Address Inefficiency, Sustainability, and the Future of Construction

As developers, designers, and contractors seek to understand the evolving needs of the modular industry, no one is as well-versed in the benefits of going modular as Mārcis Kreičmanis. As the co-founder and CBDO of LAMOD in Riga, Latvia, Mārcis has made it his ultimate goal to address the inefficiencies of traditional construction.

While coming from both the manufacturing and construction industries, he saw inconsistent quality, resource waste, and a lack of scalability. At the same time, he saw how manufacturing principles, when applied correctly, could solve many of these challenges.

As a result, LAMOD was created by a group of professionals looking to share their many years of practical expertise in the manufacturing industry. In helping new and experienced developers, designers, and other professionals in the construction industry, LAMOD hopes to give them the tools to overcome any and all modular challenges and entry barriers.

He says that with LAMOD, the group’s mission is two-fold.

One, LAMOD helps companies gain a better understanding of the process. They guide clients on how to set up the business, how to structure modular processes, and how to create effective modular teams, and basic entry strategies.

Two, they also help companies that want to expand and offer modular fabrications. In reaching out to LAMOD, they learn how to deliver large-scale, complex projects and help them grow their own business by addressing the relevant strategic and operational topics.

“That’s why we created LAMOD,” said Mārcis. “To act as a strategic bridge between traditional project stakeholders and modular technologies.”

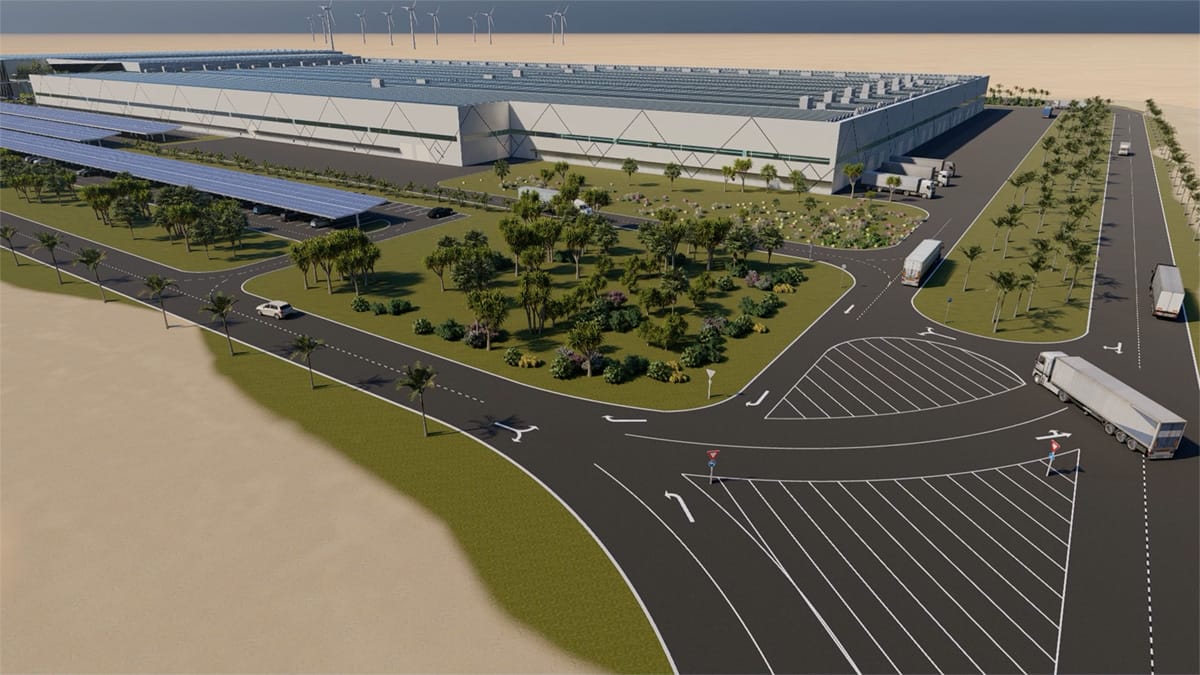

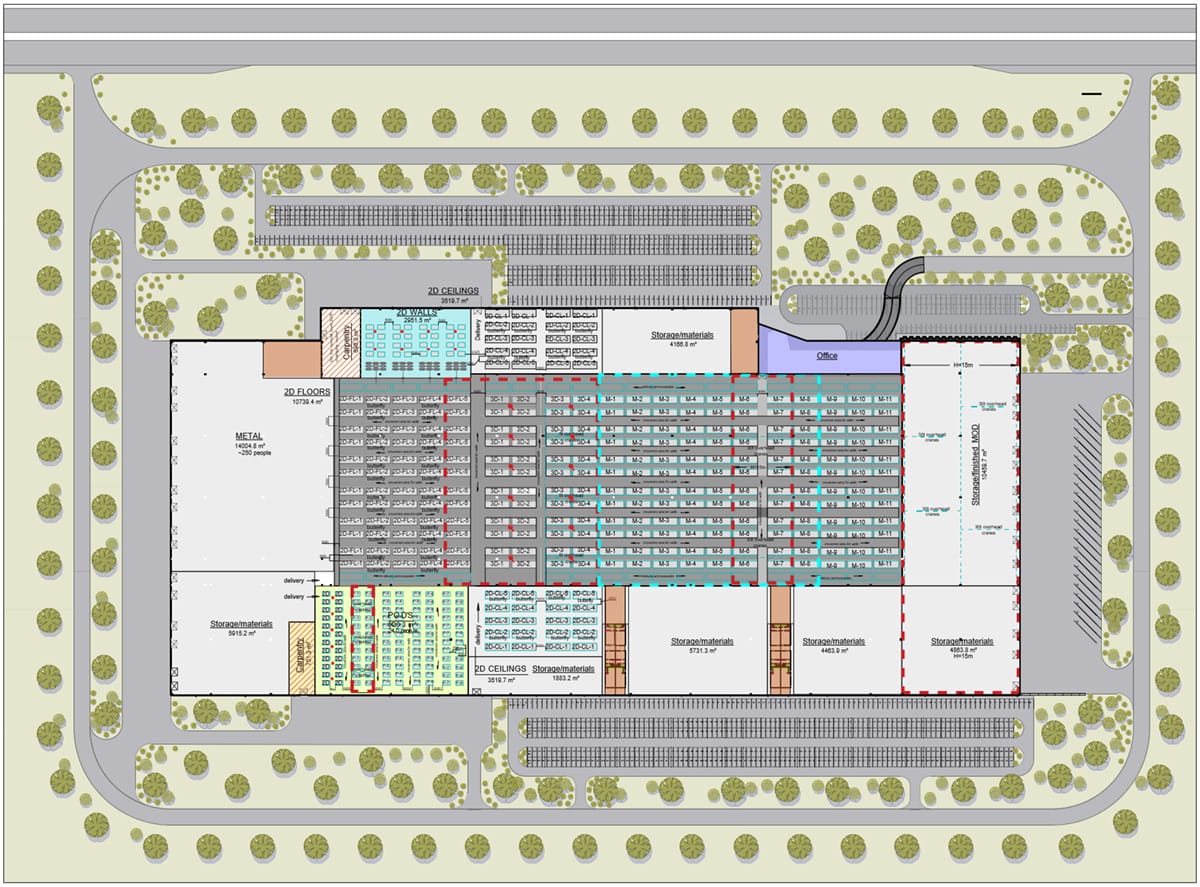

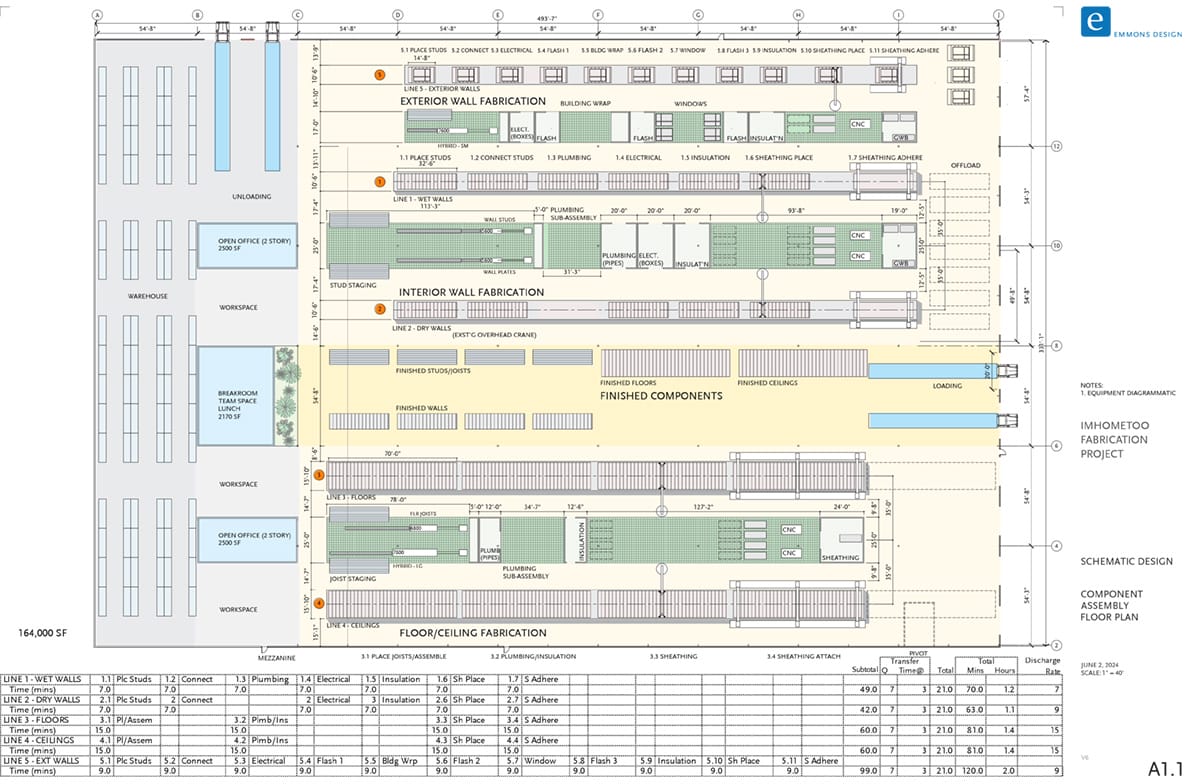

The illustrations above are intended for conceptual reference only and reflect industry-standard modular factory layouts and production principles. These examples are used for editorial purposes to convey general design logic and best practices commonly applied in modular construction.

LAMOD’s Project Services

LAMOD works with clients at any stage of their modular journey. They offer DfMA, project management, modular factory setup, and strategic consultations overall.

“Taking into account that we have been in DfMA and manufacturing for many years, we see that our scope within the modular field is nearly limitless,” he said. “If you’re talking about the execution of modular project manufacturing, we are working with many manufacturers around the world. Our goal is to evolve our company as a global platform that helps developers, manufacturers, contractors and other stakeholders to deliver modular projects at any size, or complexity.”

LAMOD has a number of ongoing projects, including one with an experienced construction partner in Portugal looking to expand into modular. Mārcis and LAMOD are helping the client develop a completely new modular facility from scratch.

“We are helping them to understand the workflows that go into the factories, understanding what kind of equipment will be needed, the number of people, and the type of skill levels, factory outputs and so on,” he said. “It’s like a complete turnkey service.”

LAMOD experts on-site, helping our partner conventional construction company embrace modular workflows and production methods to transition into modular production.

Behind the LAMOD Product Suite and Building Modular Factories

Many people in the industry use the automotive factory process as a comparison on how processes and workflows operate in modular. Building a modular factory is similar, says Mārcis. Factory design involves more than developing a place for manufacturing, as it needs to align processes with long-term business strategy.

“The modular factory design takes from both the process side and the building side,” he said. “It needs to go hand-in-hand in terms of the process before we go into the whole design, simulations, and more.”

LAMOD always starts with a strategic assessment to understand why the factory is being built in the first place. That includes evaluating the product strategy, target production volumes, desired level of automation, workforce needs, logistical or workflow constraints, and more.

With this two-prong approach, LAMOD covers both the technical side and the commercial side. The technical side consists of how the modules will be produced, what materials will be used, and how the factory will operate day-to-day. The commercial side provides companies with the ability to support scalability, market fit, and return on investment over time. It’s about a factory that can evolve as markets and technologies shift.

Mārcis and the company take cues from the modular playbook as well. In particular, LAMOD uses BIM models to help clients understand every possible aspect and potential roadblock to becoming fully operational.

“We help clients understand the full production workflow, such as workstations, cycle timing, bottlenecks, and more,” he said. “So basically, from when the first module is being placed on the line until it is fully finished. In this same virtual workflow simulation, it allows us to spot any problems before they become costly mistakes.”

While these 3D virtual models also give clients the opportunity to visualize every possibility, it cannot reinvent a client’s entire commercial strategy. For example, companies cannot simply follow one trend, only to scramble once the market evolves.

“Factories need to be focused but also flexible enough to adapt for the future,” said Mārcis.

But understanding where factories can apply long-term growth and flexibility in terms of their market offerings is part of the LAMOD offering. In fact, LAMOD has built its entire business strategy around this methodology.

The Six Steps of LAMOD’s Stage-Gate Methodology

Any new client seeking to build their own factory or expand an existing factory goes through this method, which consists of six stages: the initiation study, the feasibility study, detailed planning, bidding, implementation support, and finally, continuous improvement.

Each stage has its own dedicated actions and sub-actions that require assessments and models to help both LAMOD and the client suss out their ultimate goals.

With the initiation study, for instance, LAMOD works with the client to understand their business goals.

“These are basic questions so that we can level with the client and understand what they want to achieve with the new investment, which helps us to structure the following process in the most effective way,” said Mārcis.

For example, with the feasibility study, clients can expect to have LAMOD run through the concept design, initial sample workflows, and key targets for KPIs, according to Mārcis. This is also where digital twin modeling comes into play.

Each stage further explains the roles of key stakeholders and their roles. Another example of this involves the bidding stage, where the client interacts with suppliers to get a sense of equipment specification and pricing.

“We are helping them to assess and to prepare these bid packages for potential suppliers,” said Mārcis. “We want to help them to understand if these suppliers are relevant for this project or not.”

The Future for Modular is in Digital, Sustainability

The global demand for affordable housing is not new, but the demand for modular designed structures is growing, according to Mārcis.

“We are seeing quite closely the demand increase in Europe, Middle East and also beyond,” he said.

“There are people who are seeing good potential from the market. We came back from Malaysia a few months ago, visiting several manufacturers and developers from the region, and they see a huge demand from India, Australia, and Southeast Asia for rapid, affordable housing and other modular solutions. There are a lot of new investors in construction field who are willing to go in and explore — and LAMOD is there to support the journey.”

Additionally, modular offers a newer way to build without increasing waste and meeting sustainability goals.

“There are new and more higher sustainability policies in the Nordic countries, Germany, and Southern Europe, but abroad as well,” said Mārcis. “There are more sustainable material choices, where developers are moving from steel gauge walls to timber frame walls, recycled materials and green steel, which is steel that is being produced using renewable energy, but of course that is a project-specific topic.”

And as more developers and manufacturers enter the playing field, interest in BIM and digital twin technology grows in tandem. There are digital trends already toward investing in new BIM software, with a focus on 3D, 4D, and even up to 10D designs, according to Mārcis.

“Because if you are looking a few years ahead, there will be many building designs that will go beyond 3D,” says Mārcis. “To put it simply, you will be able to open a 3D model, click on the wall and it’ll show you what kind of materials the wall will consist, where you have sourced it, who is the supplier, what’s the sustainability level, what’s the maintenance years for that and other key information.”

Finally, modular factories and designers are seeing developers clamoring for more multifamily housing, which has been par for the course for years.

“Multifamily housing is the largest segment, and that’s clearly justified by urbanization, by affordability pressures and housing shortage,” said Mārcis. “Hotels and student accommodations are particularly strong in the areas where there’s a high tourist and academic density, so that’s basically driving this segment.”

But Mārcis is seeing newer and different kinds of modular buildings being built, particularly for the tech and military industries.

“We also see a growing segment like data centers and military infrastructure,” said Mārcis. “They’re really technical with a completely different level of design precision. You need to work with a different kind of mindset. There’s a lot of technical nuances that you need to take into consideration around thermal performance, power distribution, air flows, integration of IT equipment and so on.”

Mārcis believes this will be the future, for the next few years.

“If you haven’t built them before, it can be quite challenging,” he said. “Taking into account that we have been part of some of these modular data center projects, we have accumulated this knowledge to help build data centers accurately.”

That said, Mārcis sees the future as an opportunity for modular builders and factories to diversify their offerings to meet the needs of the market.

“With so many directions when going off-site, it is critical to stay focused,” he said. “But you need to be also flexible enough to be able to adopt to market shifts wherever these new trends take you. You need to adapt quickly and evolve.”

About the Author: Karen P. Rivera is a freelance writer and editor with a passion for storytelling. She is a former United Nations-based reporter, with experience covering international breaking news, venture capital, emerging healthcare tech, and the video game industry.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.