From Furniture Builder to ‘Activist Architect’: Stuart Emmons’ Unique Journey

Stuart Emmons was fascinated by buildings at a young age. He remembers building sand cities with his brother during trips to the Jersey shore. His father gave him his first drawing table at the age of ten, and it still stands in his office. In high school, he visited an architecture firm in Philadelphia and was also influenced by Louis Kahn’s Erdman Hall Dormitory at Bryn Mawr College, which was located near his home. Today, he is an experienced architect who received his FAIA in June 2025. The road he took is unique, to say the least.

Stuart Emmons at drawing the table his father gave him for his 10th birthday. Photo: Kathryn Elsesser.

He began his career as a master woodworker, attending the School for American Crafts and then the London College of Furniture, where he was trained in production furniture making and manufacturing plant design. Emmons said, “I liked the idea that I could design and then build what I designed from the start to the finish and have total control over the quality.” He had his own design and woodworking company, then moved into cabinet making, production management, and layout for a high-end cabinetry builder in San Francisco.

But he knew he didn’t want to be working with wood for his whole life. “I went to see a building near my hometown with my mom, and I told her all about it, as it was designed by Mitchell Giurgola (a premier firm in New York). I was describing the art, light, and architectural aspects of the design, and she just looked at me and said, ‘Stuart, you need to be an architect.’”

Emmons applied to Pratt Institute, where he earned his bachelor’s degree in architecture. After working at SOM in New York designing skyscrapers for a few years, he went back to school to get his master’s degree in architecture from Harvard. He then spent time with several firms in Los Angeles, CA and Portland, OR, before starting his own architectural firm in 1997.

Helping People Off the Street

Emmons’s passion for housing began with his first studio at Pratt, where he met Harry Simmons, Jr., an African American architect in Brooklyn, primarily known for designing and rehabilitating low- and middle-income housing in the inner city. “Harry was a huge influence on my work in affordable housing,” Emmons recalled. “I have this thing about homelessness, I’m an activist architect. I want to innovate and bring about social change. I want to get people off the street.”

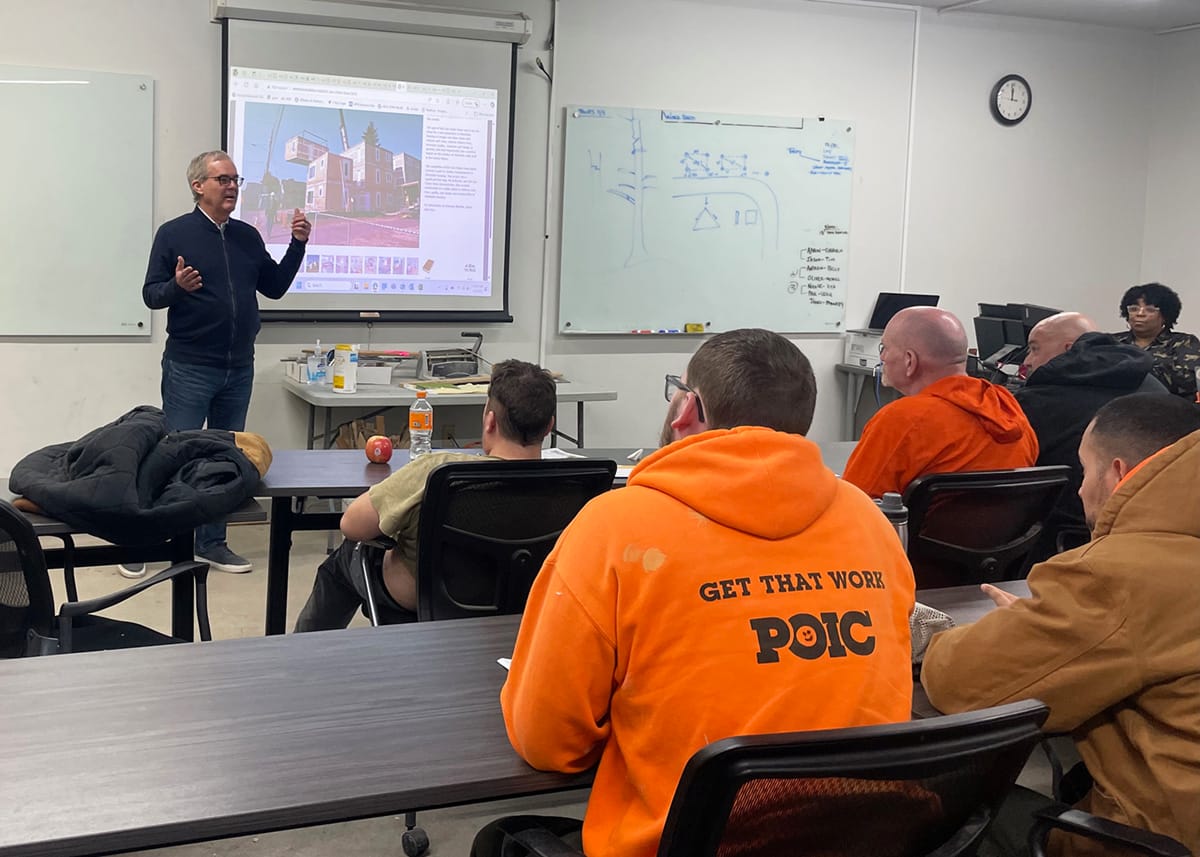

Emmons talking about modular housing with NW College of Construction students in April 2025. Photo: POIC Student.

He gained experience designing housing, including affordable housing, homeless shelters, and housing for the homeless, while working at the big firms, which fueled his passion to find new ways to deliver these projects more efficiently and affordably. With his training and experience in furniture production and manufacturing, he’s uniquely positioned to provide a fresh perspective.

In 2009, just after the recession had brought construction almost to a halt, the only available work was publicly funded projects. Emmons found that due to the overall lack of work, competition for projects was intense, as every firm in Portland, Oregon, was vying for them. A developer friend sent Emmons an email about a shipping container housing project in London. Emmons had never seen anything like it, so he figured it was a joke and responded accordingly. His friend replied, “We need to do something crazy to win one of these projects.”

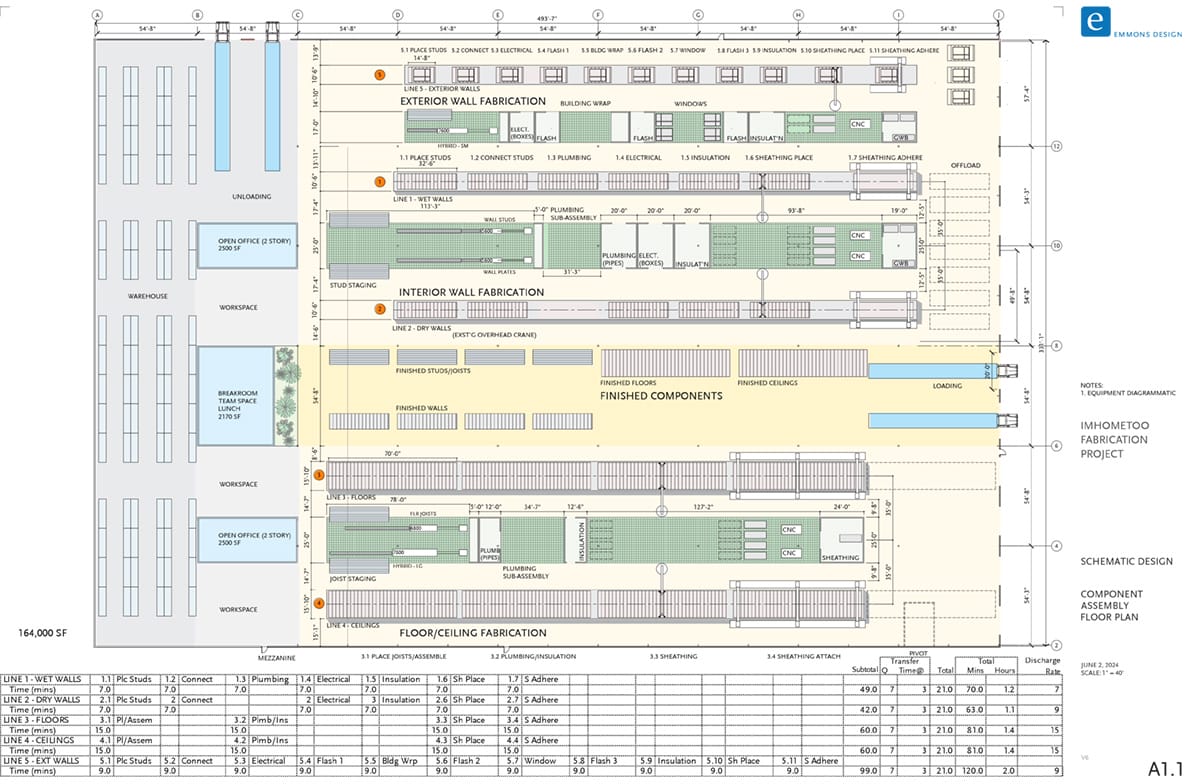

The two crafted a proposal for a prefabricated modular housing solution, and while they didn’t win the bid, the State of Oregon and the City of Portland were intrigued by the concept. They hired Emmons to write a report on modular housing. The following year, when funding became available, he submitted a proposal for a prototype modular project and was successful.

The project, called Kah San Chako Haws (“East House” in Chinook), was the first modular affordable housing project in the Pacific Northwest. It’s a nine-unit LEED Gold-certified building in Portland, OR, featuring studio, one-bedroom, and two-bedroom options, owned by NAYA Family Center, a Native American non-profit organization. The project was recognized by MBI as Modular Building of the Week in 2013.

Currently, Emmons is working on a grant with the State of Oregon and Blazer Industries regarding standardized housing units. The goal is to design modular units that can be used universally to build affordable housing. “It takes a lot of research, development, and rigor to come up with a standardized unit that achieves all the goals of accessibility and the changing codes. If we continue doing bespoke housing, we’re not going to have the kind of impact we should on the housing crisis. We need to use standardized units.”

Emmons compares it to buying a car. “You pick a car, and you can personalize it with colors and add-ons to make it feel a little bit like you. However, you can’t change the car’s chassis, saying you want the wheelbase eight inches wider or something like that. The car industry tried the bespoke thing, and it didn’t work out well because people didn’t want to buy $1 million cars.” Standardized units allow developers to replicate modules, mix and match unit types, and stack them to create buildings quickly.

A Call for Innovation

Emmons believes that the bespoke method of designing each project individually is hindering the industry’s progress. “You look at the auto industry and practically every other industry, and they would laugh at this whole housing delivery process. It’s so antiquated. With people living on the streets, I feel a calling to innovate. It doesn’t make sense to custom design every affordable housing project.”

Innovation would also attract more young workers to the industry, he feels. He’s spoken to several groups of students, learning what it would take to entice them into careers in construction. The rise of technology is transforming the trades, and automation is gaining momentum in the housing manufacturing sector.

Even though he’s had a lengthy career, Emmons feels like he’s in the middle of it. He sees the industry poised to enter some exciting, challenging times. “There’s the housing crisis, a workforce shortage that means less competition for jobs, technology, climate change and energy codes, and net zero and off-grid possibilities. This is a really exciting time to be a 20-year-old and enter this space. The rise of robotics means there’s a lot of digital and programming work that’s coming into the field. I’d love to rewind and start when I’m 20 again and go into this space because there’s so much opportunity.”

The challenge for the future, according to Emmons, is building more for the same cost. “How do you build three houses for the same price as one? How do you house ten people at the same time for the same price as a house for two people? And how do we get there?”

Inspiring the Next Generation

One way to encourage young people to get into modular, according to Emmons, is to offer modular factory and building site visits. “I think all factories should open their doors and give students access. And take them to a modular installation, with the cranes and

modular boxes flying in the air. Take them on site so they’re not just looking at a screen, but touching it, feeling it.”

ImHomeToo-Apartment (standardized units) exterior and interior. Images: Play & Co.

Emmons expects modular construction to continue growing, particularly as more emphasis is placed on standardized units for affordable housing. Modular construction can deliver higher-quality results with less risk, and financial institutions are beginning to recognize this, becoming more flexible in their funding methods.

However, the design and construction industry still needs to adapt. “Don’t take an architect’s plans and try to shoehorn them into a modular solution. Modular needs to be thought of right at the beginning, even during site planning.”

Emmons sees his work as more than plans for a building. “It’s a mission. It’s about getting people housed. It’s about dignity.”

About the Author: Dawn Killough is a freelance construction writer with over 25 years of experience working with construction companies, subcontractors and general contractors. Her published work can be found at dkilloughwriter.com.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.