Engineer Masters the Art of Listening to His Customers

The first thing that Yuri Yurianto, a modular structural engineer in Plano, TX, does when a client calls is to let the customer talk first. He listens to them discuss their project and its goals, and continues listening when they explain how they want to approach the project structurally. “I hold off on suggestions based on reviewing their drawings until I hear what the customer wants,” said Yurianto.

“If they want to use a certain design approach because the contractor is more familiar with that system, I say go with that. Even if there’s another option that, in my opinion, is more common. If the contractor isn’t familiar with it, it may not be the best option. It will require a learning curve, and they might make a mistake if I try to change it. So, I always listen to what the customer wants before I do the design, and it is more efficient to stick with the design that the customer is familiar with.”

Yuri Yurianto in his office at Modular Structural Consultants.

Since founding Modular Structural Consultants, LLC. in 2014, Yurianto has established a steady following of modular and container-based construction clients, primarily manufacturers. His services often include providing engineering calculations, reviewing drawings, and engineering certification (sign-and-seal), as well as collaborating with project teams to troubleshoot complex design cases and site-specific situations.

With structural and professional engineering licenses in all 50 US states and Washington, DC, he can provide structural engineering services for projects nationwide.

“It’s rare to find a structural engineer with deep expertise in modular and container systems who can meet the pace of the industry while also providing timely engineering services and structural certification across all jurisdictions. That’s where my role becomes vital.”

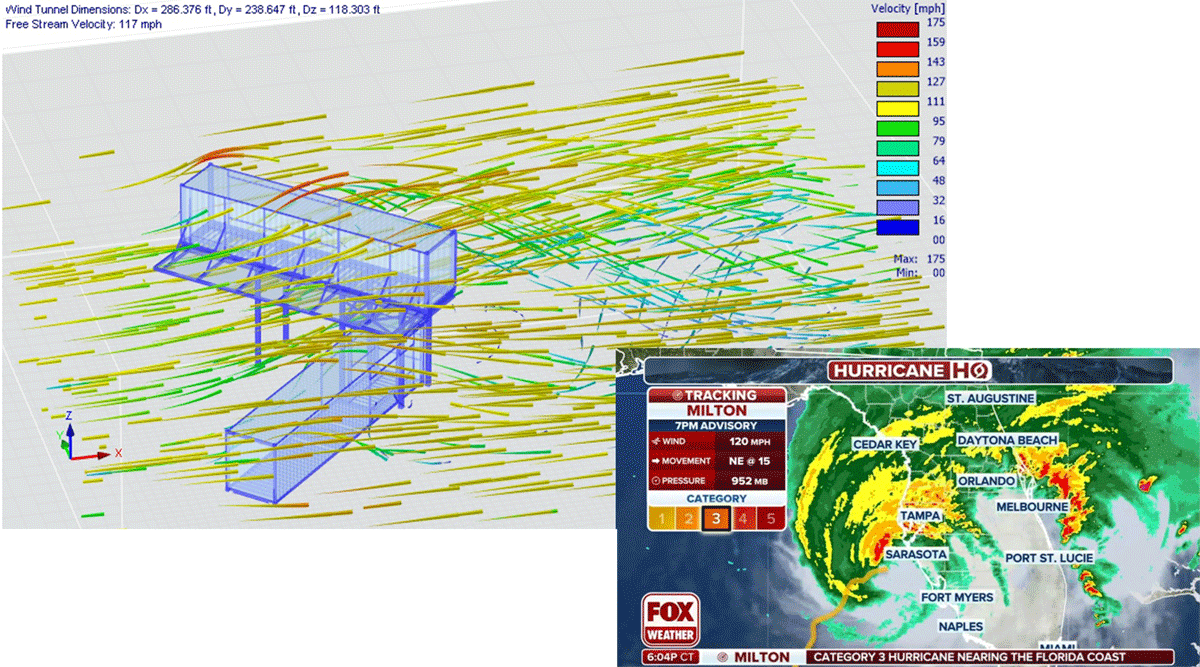

The Motor Enclave Tampa, FL; engineered by Yurianto and intact following Hurricane Milton.

Expertise and Experience

When one of his manufacturing clients reaches out, it’s usually to address a unique condition of a design case or a question from the field. Most manufacturers have internal engineering teams, so Yurianto collaborates with them to develop the best solution. He’s often called upon to review drawings to ensure they meet the design criteria for the building’s intended destination. He ensures that the design meets any special requirements, such as high wind loads for Florida or snow loads for Colorado, and provides the required calculations.

When it comes to choosing between steel- and wood-framed modular structures, Yurianto reluctantly sides with steel. “I like to work with steel better. It’s more versatile as far as connection methods go, which leads to more design flexibility. But in general, both wood and steel are just different approaches, and I don’t really prefer one or the other.”

But he’s not shy about his love for shipping containers. “I like shipping containers the most because they are the most modular structure in the world, in my opinion. You can find them everywhere, not just in the US.”

Since he only works with modular construction projects, Yurianto has extensive experience in this portion of the industry. “When you’re talking about a design, it’s not only about the amount of steel. It’s also about the constructability and how you build the reinforcing steel. You also need to think about fabrication issues, shipping, and transportation aspects. This is when my specialty and experience come together.”

While he does try to make his client’s chosen methods work, occasionally he has to make adjustments. For example, lifting design and details. “When the current design they have isn’t working, the next step is to make some modifications. I’ll begin with a minimum impact, such as adding stiffeners. I’m not changing anything, just adding something. Next, I’ll add picking points while using the same lifting lugs. That’s preferable to changing the design of the lifting lug completely. I usually take what clients usually use and do into consideration, not just tell them what to do so they have to change their process.”

The Elusive Standard Unit

The number one request he receives is for designing a standard, modular unit that can be used nationwide. He responds with a question regarding the unit’s purpose. “If it’s for a classroom or office, it doesn’t make sense to design a module that can withstand 180 mph wind in Miami, and then the same unit needs to hold a 100-pound per square foot snow load in Colorado. You end up with a bunker or a tornado shelter instead of an office.”

Instead, he asks the client where they want to market the unit. “If they’re in Texas and want to market to the surrounding states, then we can design for those locations. There’s no need to design for really high snow or seismic if you’re building in Texas. You can actually overkill on your design by doing that. I always try to explain this and find out how we can optimize their design based on their needs and plans for the business.”

Yurianto is often called on to design foundations for modular projects. There are two main options: CMU blocks or jackstands. In his mind, there’s no preferred option; it’s based on what the customer chooses. “There are some customers who stock a lot of steel jackstands, and they don’t want to go out and buy CMU blocks to build their projects. Jackstands make sense if the customer is doing more renting rather than permanent construction.”

His goal is not to hinder a project. “Most of the time, my clients already have a well-established methodology, the manufacturing crew has a certain setup they always use, and the field crew has a certain way they always build. The fastest and best way to do it is to adapt the engineering to fit those methods, rather than forcing something or a new design approach. Even if it looks like it’s a better solution, better is a relative term. Better for one client doesn’t mean it’s better for another. I stick with what they have been doing, because that is the fastest way for them to do it. In the modular industry, fast is a big thing.”

AI’s Influence on Tomorrow’s Buildings

With advancements in technology, particularly robotics, Yurianto anticipates that the speed of construction will continue to increase, which means that he’ll have to speed up his production to keep pace. “I always think that at some point they’ll be able to build a building faster than I can design it. So, I continually work to make my engineering process faster, which is not an easy task. I regularly review my process to identify what’s necessary and determine if I can improve it. I stay on top of the cutting edge in technology, including incorporating high-end computers and sophisticated design software.”

The rise of AI is sure to affect his work, Yurianto said, and he’d be naïve if he said it wouldn’t. He’s already using tools like ChatGPT to save himself time looking up data, such as the size of a specific nail. He cautions, as many have, that he can’t always trust the information he receives.

“I can get a convincing answer citing specific code sections, but when I go there, it has nothing to do with what I asked. Word of caution, it’s just a tool. It’s not the final answer. Humans will have to make the decision in the end.”

About the Author: Dawn Killough is a freelance construction writer with over 25 years of experience working with construction companies, subcontractors and general contractors. Her published work can be found at dkilloughwriter.com.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.