Eisa Lee, the "Bilingual" Architect

Translating Architecture Language for Modular Factories

Eisa Lee is one of those architects who could literally go back in time and say that her calling came to her at a young age, changing her room layout as a child every few months to fit her needs.

Now as the founder of XL Architecture and Modular Design in Ontario, Canada, she applies not just her education as a traditional architect but an entire holistic view on modular design. It’s this expansive view that guides her work on being a true partner that bridges the gap between architects and modular factories as they collaborate on the design process.

She started her own firm to retain her licensure and practice as an architect while delving deeper into the world of modular with firms like Z Modular.

It was these series of gradual choices that led her to becoming a standout architect in the modular space in Canada, focusing on

projects across North America with modular factories and other architecture firms.

An Education Entrenched in Experience

She graduated from the University of Waterloo School of Architecture, finding that her co-op terms helped her double down on her love of the trade.

While on maternity leave in 2017, Eisa’s husband Jayden went to work with Julian Bowron, the creator of VectorBloc, a volumetric modular construction system focused on scalability and precision. In 2016, Zekelman Industries bought out VectorBloc to create Z Modular.

It was then that fate intervened. Z Modular was in need of architects with deep design experience, and so off she went to work with them, first as a part-time consultant in 2018. Her husband’s move to Z Modular was the first step, but it was a gradual immersion into the world of modular for Eisa.

“[It was just a] fluke I would say that got me involved in the whole modular industry,” she said.

Eisa Lee poses with peers at the 2025 World of Modular.

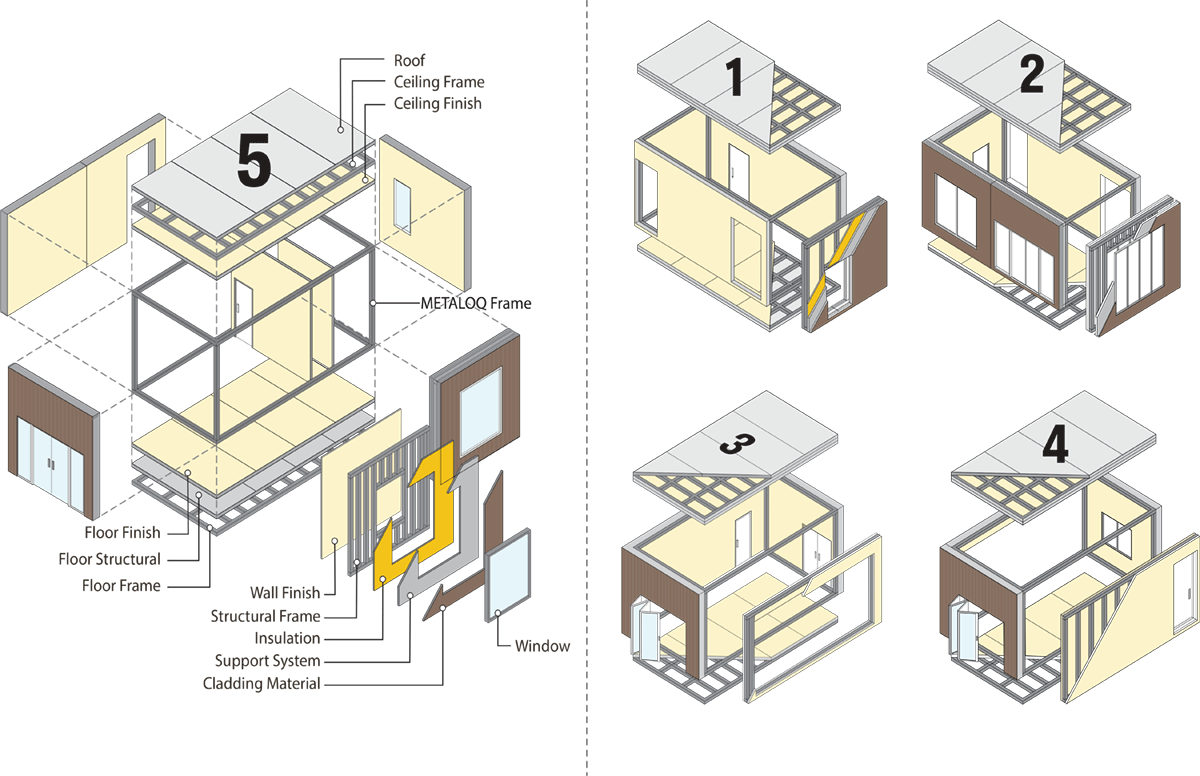

Volumetric modular assembly diagram.

Reworking Architecture Drawings for Modular Design

Eisa had to completely rethink how to apply her design chops when she first started out working on modular design projects. In fact, she had to rethink her entire way of looking at architecture in general.

“In the typical conventional world of architecture, architects are trained to think outside in,” she said. “Meaning, you have the urban fabric, your site, you see the community around it...and then you look at the approach to the building for optimal building placement, and then you do the massing.”

After assessing the outside spaces, Eisa says that’s when traditional architects then move into the interiors.

“We think about how the building’s going to look like first and then how we’re going to fit the spaces within that,” she said.

By contrast, modular encourages a focus on the inside out, according to Eisa.

“Most new architects getting into this industry are facing difficulties because for modular, the prime center of the design lies in the structure of the modules,” she said.

In particular, for volumetric modules, Eisa says that designs are dependent on the type of frame system they use. Additionally, architects must consider crucial decisions such as how connections are made and where openings need to be kept for onsite connections and more.

“Essentially,” Eisa says, architects need to first think about “how to stitch the building together at the end, before even starting a plan layout. Overall massing is determined by how you plan your spaces with your modules, which is derived from how they are getting connected.”

For Eisa, she found herself needing to not only employ this “inside-out” state of mind, but also to reach back to one of the basic tenets of architecture.

Incorporating Wholesome Thinking as an Architect

For Eisa, as an architect in the modular space, she often finds herself tasked with the role of conductor leading the construction orchestra. According to her, architects in modular tend to shift from simply designing buildings to becoming true problem solvers, employing “wholesome thinking.”

“This is not just my ego talking, but essentially, the architect oversees the entire process,” she said. “We are kind of the lead in orchestrating. So in that sense, structural [engineers] focus on the structural connections and bracing, [while] mechanical focuses on what’s theirs. Then it ultimately comes back to us to make sure that there are no clashes...I think it’s just that mindset that helps kind of think through modular construction as well, because in modular, you have to make sure you answered all your questions at the design phase, so there’s no issues during manufacturing.”

It’s this problem-solving attitude that architects must embrace, whether through training, schooling, or even sheer experience, that makes the difference when working in modular, according to Eisa.

But this mindset does take some getting used to, especially as architects tend to start out. Eisa says that most architecture students dream about “designing something pretty, and not a lot of junior staff like working on details because they’re boring and the [process] is tedious.”

That said, it’s “the details that make your design work,” she said.

For example, for multi-residential buildings with modules that have mirrored units, some architects would consider simply “flipping it on paper,” but that wouldn’t work for a modular factory, says Eisa.

“There needs to be a new set of frame designs or a new set of frame drawings, a new set of everything,” she said. “So it’s not really just about flipping.”

Architects in modular have to consider the constructibility aspects. For Eisa, that means, for instance, making sure that details like back-to-back plumbing are feasible in addition to minimizing requests for information (RFIs) during fabrication, and that everything joins together on-site.

Bilingual in Architecture and Fabrication

One of the best advantages that Eisa credits to her success is the ability to design for fabrication, rather than the purpose of only designing. Part of this is due to the fact that she started out working in modular at the factory level. After becoming entrenched in the factory ins and outs, Eisa is now able to speak two languages: architecture and fabrication.

“Instead of joining the team [at Z Modular] as an architect designing a modular building, we were actually part of the team that would take the design, redo it so that it was ‘fabricate-able’ and produce the shop drawings to make these modules,” she said.

“So we fully understand the requirements of the factory, but we also know how important design is, because we speak the language of architects.”

At XLA, Eisa and her team of five, including her husband Jayden, work on two different types of projects: designing modular buildings from scratch as the architect on record and acting as modular consultants between architects and modular factories for ongoing projects.

As a specialized modular consultant, she can relay the important requirements and considerations needed so architects can design modules to spec. Two big examples are transportation and installation, where modular designs must take in wind factors when craning over the module to the site and any shaking that the modules might experience during the trip over to the site.

What it all boils down to when working in modular, is a deep appreciation for all the trades, says Eisa.

“Architects can specify where the tile is going to start, and how it’s going to look like,” she said. “But we never think about ‘where do you start the first drywall? Is it going to be vertical?’ So we only say drywall on studs 16 inches off center. Architects may not care if you’re using four by eight foot sheets, or four by ten sheets for that matter...things that you would never think of if you’re in the traditional world. But we are thinking to that level now as we are doing the shop drawings.”

She says which materials are used, the efficiency of said installation, and layout of materials done by carpenters are all detailed layers that require review.

In many instances, XLA works with modular factories and architecture firms to conduct feasibility studies to see if designs can be turned into modular. With these clients, the firm works up production drawings up to a certain level of detail that can be translated both back to the architect and out on the floor as well.

These drawings are detailed down to the specific station or stage of production for each module, much like a car assembly line — but details are dependent on each factory, as some may not need drywall layouts or down to the paint color for each wall.

“These drawings are really geared toward what they need or want to see,” says Eisa.

‘The Greatest Energy’ at World of Modular

For her first time at World of Modular, Eisa was happy to revel in the fun and energy of the convention. She also showcased an affordable housing project, focused on building volumetric modules, or tiny homes, on surplus land owned by churches.

“Just having a room full of people rooting for the same thing is, I think that was the biggest, the greatest energy overall,” she said. “Being around regular consultants versus ‘everybody’s all for modular’ is so different.”

Her experience at World of Modular only serves to add fuel to Eisa’s mission as an architect.

“I want to create a space that people love to be in, essentially,” she said. “And if you love to be in it, you create a lot of good memories. But that space needs to be functional as a place that you create memories in.”

For architects starting out in the modular space, she is unabashed in her advice.

“Visit the factory. If you’re working with a specific client, just visiting the factory just once even helps. When you’re junior staff, going to the construction site is an exciting thing just to see how it’s coming to life.”

About the Author: Karen P. Rivera is a freelance writer and editor with a passion for storytelling. She is a former United Nations-based reporter, with experience covering international breaking news, venture capital, emerging healthcare tech, and the video game industry.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.