Behind the Design of Bethany Senior Terraces, NYC’s First Modular Passive House Senior Housing Project

As more developers seek to meet new regulations for energy efficiency, the team at Murray Engineering has set a new record. With the Bethany Senior Terraces project, Murray Engineering has helped to develop NYC’s first modular senior living structure that fully encompasses passive house principles — introducing a new era of energy efficiency in the energy-conscious city that never sleeps.

Director of Modular Design and Construction at Murray Engineering Michael Lynch, PE, SE has helped to create hundreds of volumetric modular structures across the U.S. and around the globe. In NYC, he helped to create the first-ever Shake Shack in Madison Square Park and the Boathouse restaurant in Central Park.

Michael touts an early affinity for math and science that led him down the path to becoming a structural engineer.

Early in his career collaborating with Kullman Industries, Michael contributed to the completion of multiple U.S. embassies around the world. He’s provided extensive modular design experience to the education sector, working on notable projects including Middlesex Community College in Massachusetts, and several student residential buildings at SUNY Purchase and Bard College.

“Fun fact, the cupola that’s incorporated into the MBI logo, actually came from the Middlesex project,” says Michael.

Now at Murray Engineering, Michael — alongside senior engineers Jimmy Liang, PE and William Coon, PE, SE — leads a team that specializes in creating structures for a host of industries.

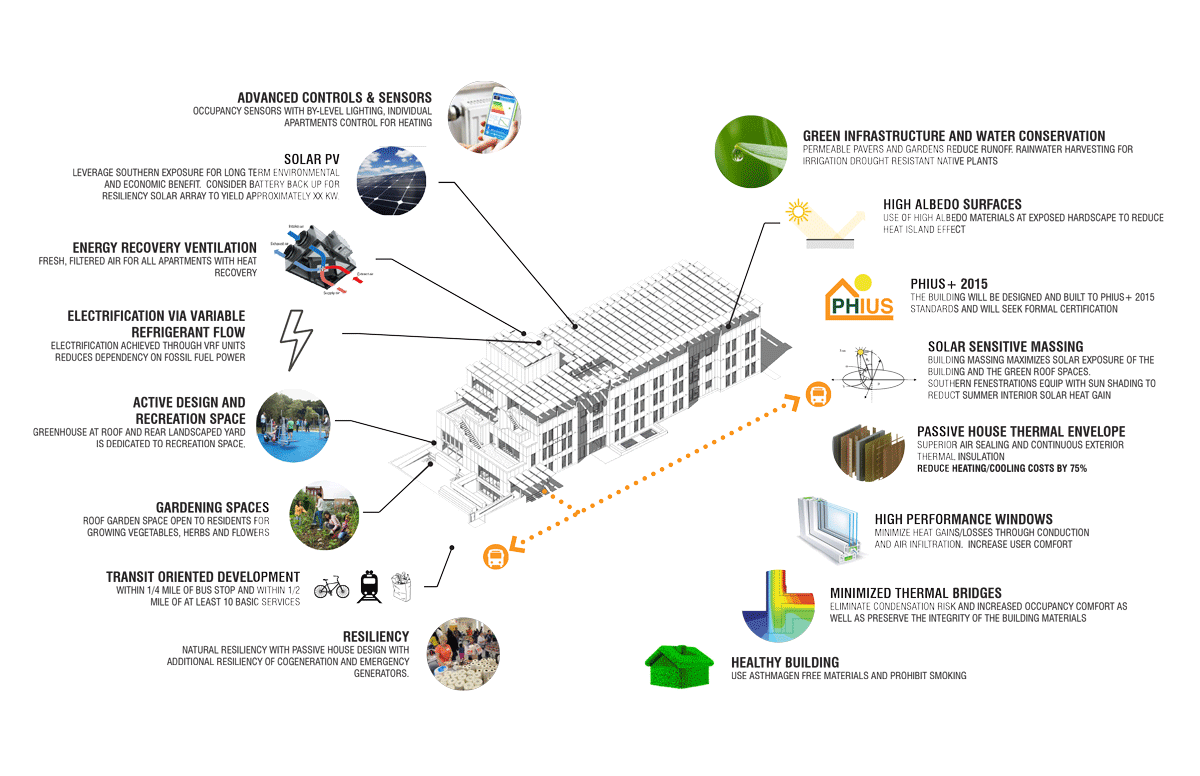

Bethany Senior Terraces Sustainable Concepts

Bethany Senior Terraces Paves The Way With Energy Efficiency

In 2019, Murray Engineering joined Paul Castrucci Architects on the Bethany Senior Terraces project in conjunction with RiseBoro Community Partnership to help increase access to affordable senior housing. Both modular and Passive House consultants were brought on to meet the particular benchmarks required for this feat.

The project experienced a temporary on-and-off pause from 2020 to 2022 due to COVID-related constraints. Fabrication of the modules by Whitley East LLC resumed in 2023, with delivery and on-site installation in Brooklyn beginning in late October of that year.

Both Passive House standards and modular construction constraints required constant coordination in order for all systems to be fully integrated, said Michael. With approximately 75 percent of the project prefabricated and 25 percent constructed on-site, clear and consistent communication was critical for alignment and connection of all building components during installation.

“There was a strong emphasis from the architect on creating outdoor recreational spaces for the residents, with a key feature being an exterior staircase that connected the various terraces to the greenhouse and common areas,” said Jimmy Liang. “Many of these elements were site-built and not part of the modular scope, so the challenge lay in integrating them seamlessly with the modular structure. Ensuring compatibility while meeting both Passive House and structural requirements required meticulous detailing. The success truly came down to resolving those complex interfaces.”

The five-story development also features a rooftop photovoltaic canopy projected to cover 100 percent of the building’s common area electricity use and about 80 percent of the entire building’s energy use.

The building received its Temporary Certificate of Occupancy in July of 2024 and residents are continuing to move into the property.

MEP and in-factory module views of Bethany Senior Terraces.

The Modular Lessons That Led to Bethany Senior Terraces

Volumetric modular design must consider transportation constraints on module size and weight. Oversized or overweight modules present logistical challenges for trucking, shipping, or air transport, each requiring specific design considerations for transportation loads and can impact cost.

With these considerations in mind, Murray Engineering drew on their experience to maximize the size of the modules. The result was a design that was 14 feet wide by 60 feet long.

“We worked with a modular consultant, AMSS, to plan the route from Pennsylvania to the George Washington Bridge in New York and the busy streets of Brooklyn,” says Jimmy.

Due to the length of the modules, the modular manufacturer used a special lifting beam — interestingly enough, the same one Michael designed while collaborating with Kullman years before.

“We constructed a total of 48 modules to accommodate 58 residential units,” said Michael. “By utilizing a double-loaded corridor configuration, with studio units on either side, we maximized spatial efficiency and achieved a highly effective modular layout.”

A “double-loaded corridor” layout places a public corridor at the center with units on both sides. The placement of the Mechanical, Electrical, and Plumbing (MEP) shaft in each unit was strategically placed in the corridor and was left unfinished. This provided the accessibility to facilitate the ease of making the plumbing riser connections in the field and to enable most of the modules to be finished in the factory.

Modular construction demands a high level of coordination between all trades and key stakeholders. Michael recalls a project from 2017 in which Murray Engineering collaborated with a European builder to develop a compact and cost-effective ceiling/floor system. Unfortunately, they hit a snag when trying to incorporate floor drains.

“We discovered that we couldn’t fit a standard floor drain within the module,” says Michael. “The mechanical team had to source a specialized drain that would fit in the limited space. Fortunately, we found one, but it was significantly more expensive than a conventional option. This was a hotel project with 300 rooms, so that added cost became a major factor.”

The experience provided a valuable lesson in maintaining close collaboration with MEP consultants, as the team understood how important it was to allocate adequate space for MEP systems and that all components are properly integrated into the modular framework.

Satisfying Passive House requirements adds another layer of complexity. Michael noted how Murray’s extensive experience working with other consultants and modular factories prepared them well for the specific challenges of Bethany.

“It was a challenge to fit all of the MEP system components within and alongside the structure without sacrificing the architectural design,” he said. “We also needed to make sure that structural components and connections did not undermine the building envelope. We incorporated thick blocks of load-bearing rigid insulation into the connections of the solar canopy posts to our modules to minimize thermal bridging between the exterior and interior spaces. Frequent sharing of Revit models between consultants was important to this project’s success.”

The Practical Partnership Between Energy Efficiency and Modular

More regions are introducing important sustainability regulations for affordable housing structures, and New York City is no exception. However, modular design and energy efficiency can work hand-in-hand, making it an ideal construction method for those looking to create airtight structures.

Passive House design principles consist of five specific techniques for peak energy efficiency: super insulated envelopes, airtight construction, high-performance glazing, thermal-bridge-free detailing, and heat recovery ventilation.

Applying these techniques to modular construction can be complex, but according to Jimmy, modular methods can significantly support energy efficiency goals, often more effectively than traditional stick-built construction.

“If planned correctly, modular construction offers a major advantage in improving energy performance,” says Jimmy. “Factory conditions allow for near-ideal quality control, especially in sealing joints, which is crucial for airtightness. Modules are protected from weather exposure during fabrication, and they’re only exposed briefly during erection. Compared to conventional construction, modular erection is significantly faster, which further limits exposure.”

Achieving energy efficiency targets, such as those outlined by Passive House standards, requires buildings to be exceptionally airtight. However, as Michael points out, airtightness alone is not sufficient.

“As we’ve learned, tighter buildings don’t automatically equate to healthier buildings,” said Michael. “To maintain indoor air quality while minimizing energy loss, we now rely on equipment like Energy Recovery Ventilators (ERVs). These systems exchange stale indoor air with fresh outdoor air, simultaneously transferring heat and moisture between the two air streams, improving both efficiency and comfort.”

In modular construction, the ability to test and verify energy performance in a controlled environment is paramount to meeting efficiency goals. Blower door testing is just one example of this, according to William Coon.

“A blower door test measures how airtight a building is,” he said. “We can assemble a full apartment by joining a few modules together in the factory, seal the joints, and run the test to detect leaks. It gives us the chance to troubleshoot any issues before the modules ever leave the factory. Once everything is erected on site, the test must be repeated, but early testing in a controlled setting often reduces the time and cost associated with fixing deficiencies later.”

NYC’s First Passive House Modular Structure Garners Acclaim

In 2024, the project won the Blue Ribbon award of distinction in NYSERDA’s Buildings of Excellence Competition and first place in the Permanent Modular — Social & Supportive Housing category in MBI’s 2025 Awards of Distinction.

As Bethany Senior Terraces gathered attention for its unique combination of modular and energy efficiency design, the team at Murray Engineering presented the project at the 2025 World of Modular to an enthusiastic audience.

“We received a lot of comments afterward from attendees who were genuinely intrigued by the project,” said Michael. “It really resonated, particularly in urban contexts, where energy codes are more stringent. Modular makes a lot of sense in those environments, and I think this approach reflects the direction the industry is moving toward in the future.”

About the Author: Karen P. Rivera is a freelance writer and editor with a passion for storytelling. She is a former United Nations-based reporter, with experience covering international breaking news, venture capital, emerging healthcare tech, and the video game industry.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.