How Caster Concepts Redefined Durability in Modular Construction

The Challenge: Replacing Casters Was Becoming a Six-Figure Routine

Autovol, a trailblazer in the automated modular housing industry, is known for transforming the way homes are built. But behind the innovation was a costly problem lurking beneath the surface.

Supporting modular units weighing over 50,000 lbs., the casters on their transport platforms were failing at an alarming frequency. Every three years, these casters needed full replacement. Factoring in labor, equipment, and lost productivity, the cost of each replacement approached $50,000 per caster. For a high-tech company focused on efficiency and automation, this recurring downtime was unsustainable.

The root of the issue? Traditional heavy-duty casters simply weren’t engineered for the extreme demands of Autovol’s modular construction loads. Frequent failures, high maintenance, and operational slowdowns became a challenge that Autovol wanted to solve as quickly as possible.

The Solution: Engineering Beyond Industry Standards

Autovol turned to Caster Concepts, a U.S.-based leader in application-specific heavy-duty casters. With a track record of solving industrial- scale challenges that others manufacturers couldn’t or wouldn’t touch, Caster Concepts approached the problem not just as a supplier — but as an engineering partner.

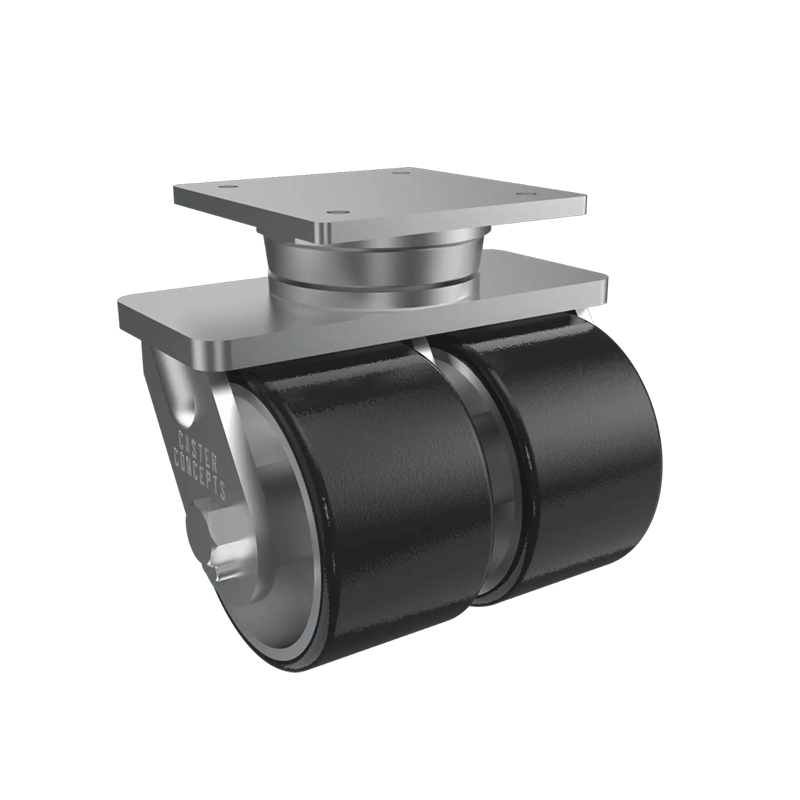

The solution to the problem was ten 81 Series Kingpinless Heavy-Duty Casters, each rated to handle over 10,000 lbs. Built with a single-ball race swivel design, the 81 Series excels in high-impact environments where shock loading, durability, and maneuverability are non-negotiable.

Why it worked:

- Kingpinless Design: Eliminates the most common failure point — ideal for rough modular site terrain and omni-directional loads.

- Shock Load Resistance: Built to withstand vertical and horizontal stresses common in modular applications

- Ergonomic Engineering: Designed to reduce push force and promote smoother movement, contributing to both safety and efficiency.

- Exceptional Materials: Featuring polyurethane wheels with high tear resistance and steel frames designed for extended life

under load.

The Results: From 3-Year Replacements to a 5-Year (and counting) Run

Five years later, not a single caster has needed replacement. Autovol has doubled the lifespan of their previous caster solution and still going strong. The change has saved the company hundreds of thousands of dollars in maintenance, labor, and lost productivity.

Other benefits of the 81 Series Kingpinless Caster:

- Zero Downtime from caster failure since implementation

- Improved Workflow Efficiency with more predictable movement

- Safer Load Transfers with reduced risk of caster collapse

- Lower Total Cost of Ownership — a long-term return on investment

As Greg Sykes put it, these casters are “bulletproof.”

“Caster Concepts casters are, BY FAR, the best, most bulletproof HD casters I have ever seen.”

— Greg Sykes, Maintenance Director, Autovol

Technical Spotlight: The 81 Series Kingpinless Caster

The 81 Series is a staple in Caster Concepts’ extreme-duty portfolio. Designed for continuous use in abusive environments, it’s built for loads starting at 5,000 lbs and up, and is frequently deployed in aerospace, military, and now modular construction sectors. It features a unique single ball race design, which provides a high strength swivel section.

Conclusion: A Case for Smarter, Stronger Casters in Modular Construction

The Autovol partnership demonstrates how engineered caster solutions from Caster Concepts solve problems that others can’t.

In a world where modular construction is scaling rapidly, mobility components matter more than ever. Casters are no longer a commodity — they’re critical to uptime, workflow, and ROI.

Two companies. One solution built to last.

For Autovol, the result has been more than peace of mind — it’s been a measurable performance upgrade.

For more information on any of our heavy duty casters, call 888-781-1470 or visit CasterConcepts.com.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.