Enthusiasm for Modular Construction Grows in Ukraine as Rebuilding Efforts Take Shape

The future of Ukraine may be uncertain, but one thing isn’t: rebuilding will be a monumental task.

Bruce Talley, Chief Operating Officer at MBI member company OFC Incorporated, is trying ensure that Ukraine’s eventual rebuilding efforts are based in a technology known for its speed and adaptability: modular construction.

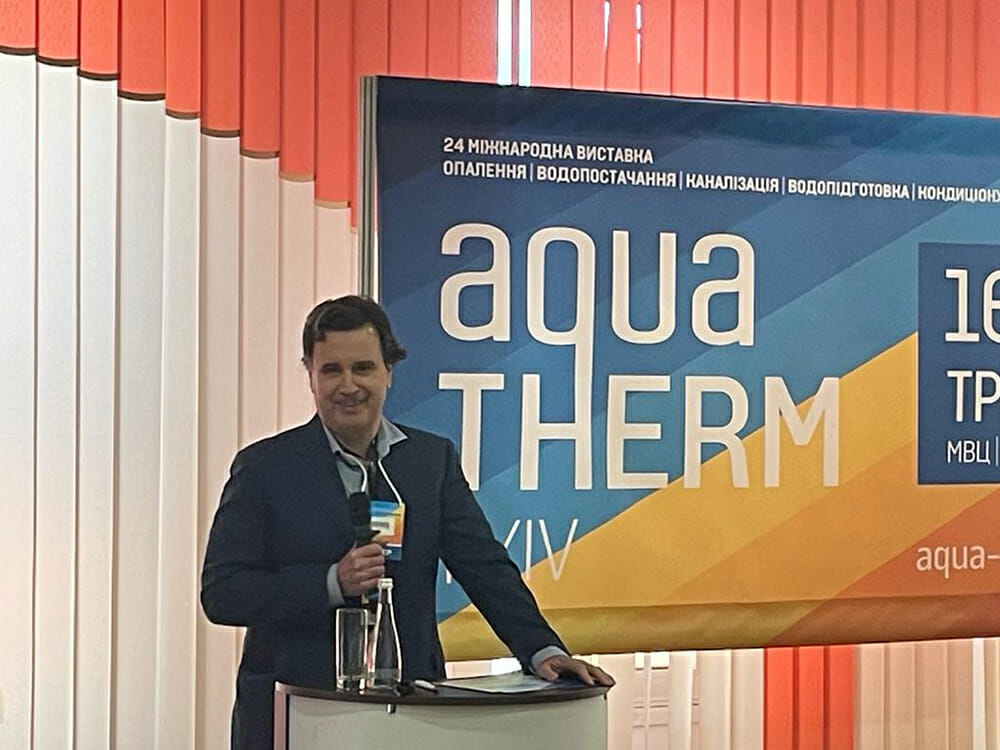

During his most recent visit to Ukraine, Talley was invited to share his knowledge of the industry at several building conferences. His first stop: KyivBuilds.

Bruce Talley, chief financial officer at OFC Inc., speaks at KyivBuilds in May, 2023.

Hosted in Ukraine’s capitol May 16-17, the KyivBuilds conference was attended by over 7,300 people with 161 companies exhibiting. There Talley spoke to a group of Ukrainian mayors, developers, and architects about modular housing. Talley then traveled to Irpin and Zhytomyr to talk about modular building applications in those cities.

“The quality of modular building and the uses are much greater than I realized. Modular building will be in great demand in Ukraine to solve housing,” said Oleksandr Markushin, Mayor of Irpin.

“I learned a lot from Bruce's presentation. I think modular building will be very important for Ukraine's rebuilding,” said Artem Shira, director of Nerex, a water treatment and purification company.

Bruce also presented at the UNation conference in Odesa on May 20, 2023.

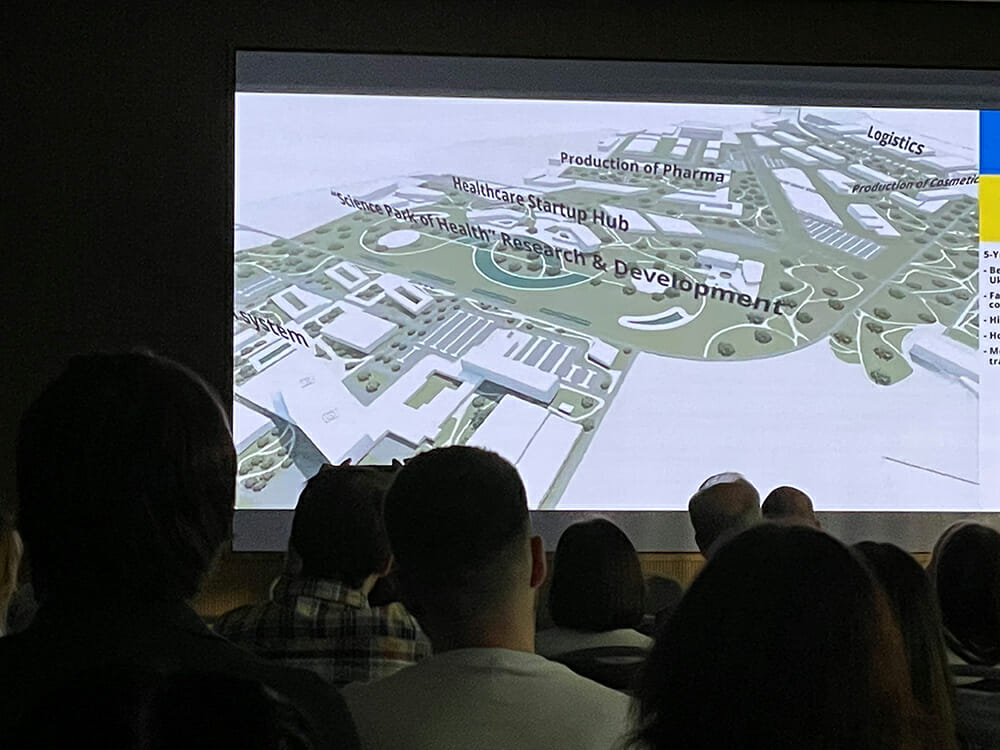

Following his talks in Kyiv, Irpin, and Zhytomyr, Talley attended the UNation conference on May 20th in Odesa. Topics included rebuilding, tech incubators, and the reforms that Ukraine needs to instate to attract foreign investment, as well as regional issues affecting Odesa. Also discussed were several large business parks to be developed in Ukraine, with retail, housing, Olympic training, medical, offices, and redevelopment of an airport.

Related Listening:

Rebuilding Ukraine: What Modular Manufacturers, Dealers, and Developers Need to Know w/ OFC, Inc

Bruce Talley, chief operating officer of OFC Inc., discusses the current conditions inside Ukraine, including the state of its infrastructure and housing, and recounts his personal experience and observations from recent visits. Bruce also shares important information for modular companies looking to help in the relief and rebuilding efforts.

The opportunities for modular construction in Ukraine, it seems, are boundless. But for the industry to make an impact, inroads will need to be made.

“In general,” said Talley, “I’m in Ukraine to meet with people, look at potential production sites (especially in western Ukraine, but not limited to there), and discuss modular housing and container conversion applications for apartments, homes, retail, offices, schools, and hospitals. Everyone is interested in solutions that will save time and money and control costs and outcome. Clearly, employment is driving a lot of thought. However, at each event I have attended that has been a lot of discussion around Smart Cities and sustainable development. So much has been damaged in some areas, that instead of rebuilding like it was, cities will look and work differently with new infrastructure.”

It's early yet to make predictions on when rebuilding efforts can be made in earnest, but Talley sees an opportunity for the global industry to get involved when the time is right. That said, it won’t be a cake walk.

“When we're talking about getting involved in Ukraine, there is a steep learning curve," says Talley. "There are cultural and legal barriers that will be new to many, especially to North American companies. So, it's possible. But if a manufacturer or builder wants to acquire our abilities, our knowledge, our culture, cultural understanding and language skills, and ability to bridge that gap, I think we can do that very well.”

About the Author: John McMullen, PCM, is the marketing director for the Modular Building Institute. You can reach him directly at mcmullen@modular.org or on LinkedIn.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.