Demand Booms for Modular Cleanrooms: G-CON Delivers

José Negrón is a process architect at G-CON, a manufacturer of prefabricated modular cleanrooms.

José Negrón is a process architect at G-CON, a manufacturer of prefabricated modular cleanrooms, which the company calls PODS. His role involves a combination of engineering and architecture. At the beginning of a project, his goal is to fully understand all the steps of the client’s production process, “starting from how they get raw materials into their warehouse; how they check the quality of the materials; every step of their production line; the flow of people and materials through the process; all the way to the finished product going out the door.” With that understanding, Negrón can design a POD layout that best serves the client’s processes and equipment.

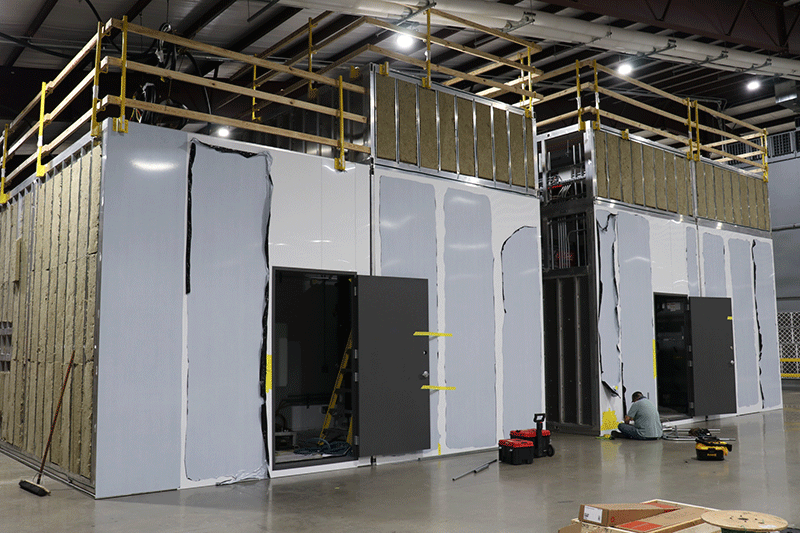

The PODs structures are made by welding aluminum members. Some extrusions are patented aluminum shapes that provide higher load bearing capacity than typical extrusions.

The PODs are fit-out at the factory with the necessary architectural components, in addition to the mechanical, electrical, automation and fire protection systems.

Product Design

Cleanrooms often have smaller rooms adjacent to them, called airlocks. Airlocks are used for people to gown-up, or for materials to go in or out. These actions take place in the airlocks so the proper environmental conditions can be maintained inside the cleanroom. Depending on the process, some airlocks are bi-directional, and some are uni-directional.

The superstructure of each cleanroom POD is made of aluminum, which is strong, light, and corrosion-resistant, all significant advantages over steel and wood construction. G-CON builds each POD frame in their fabrication shop. “The PODs are then combined with pre-assembled architectural and mechanical systems,” Negrón says.

“Fresh outside air is pre-conditioned with a make-up air unit to remove particulates and to get the temperature and humidity within a certain range,” Negrón explains. “Within each POD, there’s a dedicated HVAC system that receives the pre-treated air and pushes it through a number of filters. The final HEPA [High Efficiency Particulate Air] filters are in the cleanroom ceiling.”

Once the air flows into the cleanroom and reaches the floor, low wall return chases remove it from the room. “Any particulate matter that might be in the air goes down to the floor and out through the low wall returns,” Negrón adds. This airflow ensures no particulates accumulate in the corners of the cleanrooms. Coving where the walls meet the floor and ceiling also help achieve this.

Strict Requirements

In the pharmaceutical industry G-CON serves, there are different regulatory requirements for various aspects of a client’s processes. For example, air cleanliness and room classification requirements will vary depending on a client’s manufacturing processes.

In addition, many clients have very specific, rigorous cleaning protocols for every surface of the cleanroom, including the floor, walls, and ceiling. The materials for the interior surfaces must be able to withstand the cleaning chemicals used and the cleaning frequency.

In many cases, G-CON’s clients need to be able to prove to regulatory agencies that their products — such as vaccines — have been manufactured within strict environmental parameters. This means they must collect data on air temperature, relative humidity, air pressure, and other factors. “The data needs to be digitally collected, saved, and protected in such a way that nobody can tamper with it,” Negrón explains. “So, if someone from the regulatory agency asks for the data regarding a specific batch of vaccines manufactured at a certain time on a certain date, all that data is available.”

Modular Manufacturing Advantages

Building in a controlled, indoor environment means that it’s much more feasible to keep the product clean during construction. “Before shipping, we have a list of tests we perform on each POD in the factory. After they’re tested, the PODs are prepared and shrink-wrapped for shipping and delivery,” Negrón says. Once the cleanroom PODs are installed at the client’s facility, G-CON cleans them again. “For commissioning, we test the POD systems once more.” The client then does the final sanitization prior to operation.

SubPODs are joined together with clean corridors that lead to airlocks, pass-through boxes and other material transfer elements.

Negrón says that more and more clients are turning to prefabricated modular cleanrooms “because of the high quality, cost certainty, predictable schedules, and the ability to deliver projects much faster than traditional construction.”

Another advantage of POD cleanrooms is that they can be used temporarily and then re-located. Clients can use the cleanrooms for as long as they need them and then re-deploy them for another use or sell them. With traditional stick-built cleanrooms, the building expenses are sunk costs because the cleanrooms can’t be moved or re-sold as independent units if they’re no longer needed. Also, a small manufacturer can begin operating with one cleanroom POD and add more as the company grows and requires additional capacity — because each POD is completely self-contained.

Depending on the client’s process, subPODs can be joined together to form a POD cluster. Projects vary from 1 to 14 plus subPODs. Interconnecting the PODs allows clients to have great layout flexibility.

Greater Demand and Increasing Standardization

The demand for cleanrooms has been very high over the past couple of years. “When COVID hit, some clients put projects on hold. But we were also inundated with new requests for cleanrooms, to support the global COVID response, including vaccine manufacturing,” Negrón says.

This increased demand has resulted in rapid growth for G-CON, including greater manufacturing footprint, capacity, and head count. At the same time, G-CON is moving towards more standardization of its POD systems to further reduce the time and cost for delivering cleanroom facilities. The company recently released a catalog of standardized POD designs. These standard models can address the needs of cell and gene therapy companies, or can handle fill-finish. (Fill-finish is the final step of filling, labeling, and packaging vials of medications before they’re distributed.) The idea is that the standardized PODs will provide enough variety and flexibility for clients to mix and match, while also providing the speed advantages of standardization. “Standard PODs can be ready for delivery in three months, whereas if a client requires custom POD designs, it might take six months to a year to deliver the PODs, depending on the project size,” Negrón says.

World of Modular Presentation

The main focus of Negrón’s World of Modular presentation is to show how G-CON delivers projects faster than regular construction methods, helping companies take drugs and therapies to market faster, saving patients’ lives. Cleanrooms must adhere to strict standards imposed by regulatory bodies such as the FDA, and Negrón will talk about how the manufacturing process for cleanrooms differs from ordinary modular prefabrication.

About the Author: Zena Ryder is a freelance writer, specializing in writing about construction and for construction companies. You can find her at Zena, Freelance Writer or on LinkedIn.

More from Modular Advantage

Celebrating the Winners of MBI’s 2025 Awards of Distinction

MBI’s Awards of Distinction are presented annually, traditionally on the final evening of its North American World of Modular conference and tradeshow. This year’s Awards were presented in a variety of categories, including several each for permanent modular construction projects and relocatable buildings. Excellence in “green” modular construction and marketing were also recognized.

MBI Welcomes R.I. Group Founder & President Salvatore Tafuro to the Industry’s Hall of Fame

In 1973, Salvatore Tafuro, only in his twenties and already supporting a family of three children, set out to realize his entrepreneurial dream. From a humble garage in Leverano, in the heart of Salento, he began producing metal structures and aluminum fixtures for the construction industry.

The Best-Kept Secret in Housing

What can we do to right the ship, overcome these circumstances, capitalize on the opportunity, and address this epidemic in the housing sector? It’s easier than you might think.

The Blueprint for Accountability: How Mastery, Autonomy, and Purpose Drive Performance in Construction & Manufacturing

Accountability is one of the most critical elements of a thriving organization, yet many leaders in the construction and manufacturing industries struggle to create a culture where it truly thrives. High-performance teams require more than just technical skills and efficiency—they need strong accountability, alignment with the company’s vision, and a deep sense of ownership.

AI, Faster Sets, and Automation: The Future of Modular is at World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

An Insider’s Guide to the 2025 World of Modular

The Modular Building Institute is bringing its global World of Modular (WOM) event back to Las Vegas, and with it comes some of the industry’s best opportunities for networking, business development, and education. Over the course of the conference’s four days, there will be numerous opportunities for attendees to connect, learn, and leverage event resources to get the most out of the conference.

Affordable Housing Now: The Industry’s Best Bring New Solutions to World of Modular

While the modular building industry has long known that it can be an effective solution to increase affordable housing, the word is slowly spreading to more mainstream audiences. Three presentations at this year’s World of Modular in Las Vegas hope to provide insight and direction for those seeking a real solution to the crisis.

Opportunities for Innovation in Modular Offsite Construction

Modular Offsite Construction has already shattered the myth that it only produces uninspired, box-like designs. Architectural innovations in module geometry, configurations, materials, and products make it possible to create visually stunning buildings without sacrificing functionality or efficiency.

Safe Modular Construction with Aerofilm Air Caster Transport

In collaboration with Aerofilm Systems, Heijmans developed innovative skids using air caster technology for moving modules easily and safely. These pallets are equipped with an auto-flow system, making operation extremely simple.

Miles, Modules, and Memes: Building a Modular Network One Flight at a Time

At the end of the day, social media is just another tool for building connections, and like any other tool, needs to be used skillfully to work properly. Use social media thoughtfully, and it will open doors to real opportunities and relationships you didn’t even see coming.