Offsight’s Value Add to Your Factory

About the Author: Andrew Xue is the chief operating officer at Offsight, a developer of factory project management software for the offsite construction and building components industry.

The offsite and modular construction industry is booming. Over the coming 5 years analysts predict a fundamental shift in the construction industry, resulting in a new $256B annual profit pool up for grabs. This new demand has incentivized the founding of many new factories and the expansion of many currently operating modular businesses. These factories, which are at various stages of production maturity, face an important choice. When is the best time to implement technology and is technology needed to improve and manage quality reporting and operational processes?

In this article, we outline the value of Offsight’s factory project management software across several clients that participated in case studies after implementing Offsight:

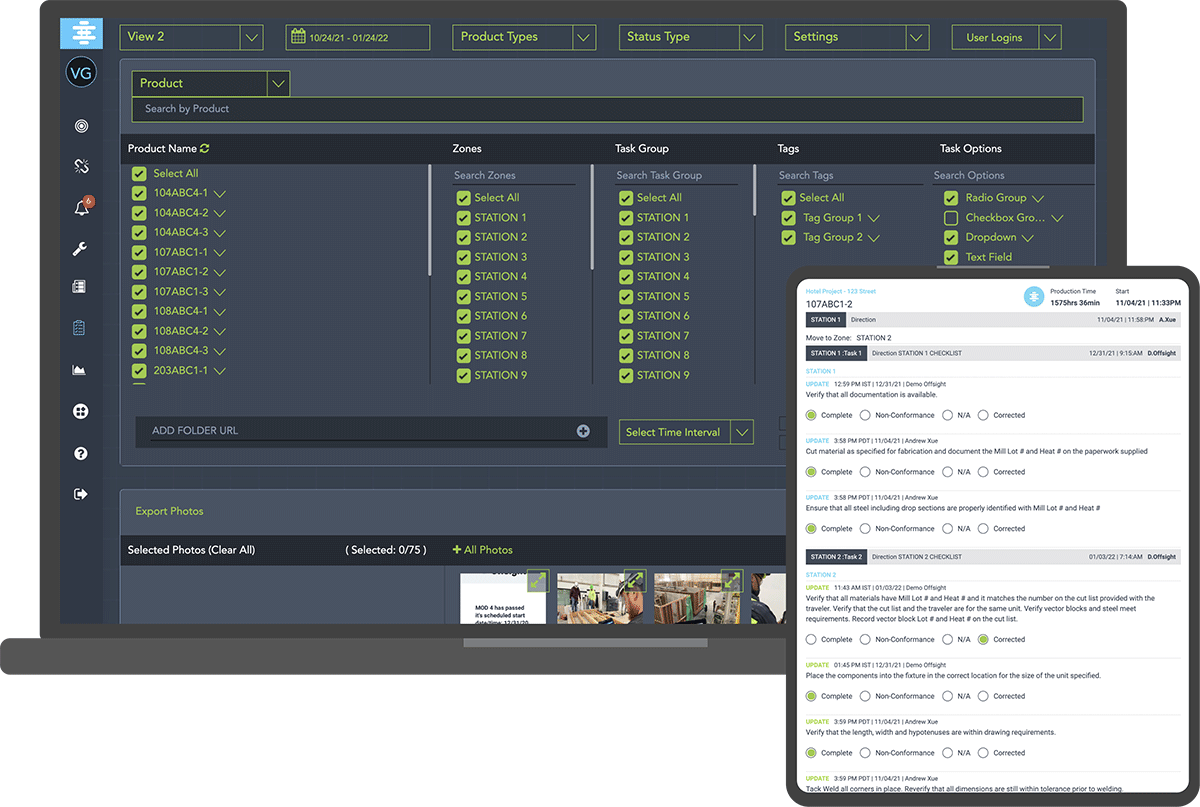

- Volumetric Building Companies (VBC) is a vertically integrated manufacturing and construction company that uses Offsight’s project management software to provide module-level visibility to all critical stakeholders and ensure every offsite project is successful. Offsight provides a multitude of customizable checklists to track production and quality of each module. After module delivery, Offsight digitally stores the entire history of the module and all relevant activity in the History tab. This includes all production interactions such as images taken on the factory floor, checklists completed and production data, which can be leveraged for future offsite projects.

- Z Modular, a subsidiary of industry steel giant Zekelman Industries, has implemented Offsight’s project management software at their Chandler, AZ and Killeen, TX modular manufacturing facilities to streamline product quality and production progress tracking. Offsight’s software helps manufacturers maximize scalability in their process, coordinate with many internal and external project stakeholders and provides a level of flexibility necessary to accommodate a wide variety of commercial modular projects.

See our Online Case Studies

The rapid rise of offsite and modular construction across multifamily, commercial, affordable housing, workforce housing and hospitality projects have shifted work from the traditional construction jobsite to the factory. With this process shift and move to modular, owners and project stakeholders are increasing their expectations around managing production quality and reporting at the factory level. In this case study, we walk through how industry leaders leverage Offsight to track factory quality and manage crucial internal and third-party reporting.

The global modular construction market is booming and expected to exceed $100B by 2025 with steel modular construction expected to be the fastest growing segment over the next 5 years. This bodes well for many steel modular manufacturers, including Offsight’s customer Z Modular.

Check us out at the 2022 World of Modular

Implementing Offsight’s technology, even at the early stages of your factory’s prototyping and design production stage, helps you avoid rising operational costs and position your business as an innovative and thought leading brand for operational and quality excellence from day one. If you’re interested in learning more, we encourage you to visit our booth at the 2022 World of Modular Conference. You can check out our product in action or reach out to our team directly at sales@offsight.com to schedule your private demo.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.