Exploring the Role of Modular Integrated Construction (MiC) in Advancing Circular City Principles - A Survey of Stakeholder Perspectives

Joachim Zwicky is a PhD-Candidate in Business Model Innovation at the University of Aveiro.

Step into the year 2035, where cities have become circular or let’s say it like this: they have become engines of value creation—waste is designed out, and every built asset contributes to a thriving, resource-efficient urban ecosystem. Across these circular cities, residential developments set new standards: constructed 100% modularly, every building element is serially produced, fully demountable, and engineered for reuse or recycling at the end of its service life. For industry leaders, this isn’t just a vision, it’s a scalable business case.

Why? Because modular integrated construction (MiC) fundamentally reshapes the way we design, deliver, and manage buildings. Standardized processes and digital workflows drive higher productivity, minimize delays, and deliver predictable quality at every stage. Materials, once immobilized in outdated structures, remain assets—retaining value and enabling new revenue streams from refurbishment, resale, or material recovery.

For developers and investors, the result is lower lifecycle costs and resilience against resource volatility. Municipalities and operators benefit from greater speed, flexibility, and reduced urban disruption—meeting stakeholder expectations and regulatory targets for sustainability. End users experience better living environments, adaptable housing, and transparency in environmental performance.

In this context, MiC is not only a tool for innovation but a competitive advantage—enabling the industry to meet circular city objectives, respond to market shifts, and unlock profitable growth.

This article explores the findings of a targeted stakeholder survey, translating circular principles into actionable strategies for decision-makers in modular construction.

This survey forms a key part of a PhD thesis which investigates innovative and sustainable business models for modular building systems. Between January and July 2025, responses were collected from stakeholders mainly across Europe, the Americas, and Australia/New Zealand. The respondent pool included building contractors, project developers, architects, civil engineers, industry associations, and academics. The structured questionnaire comprised 14 core topics with in-depth sub-questions, aimed at capturing practical insights from various professional perspectives. Selected survey questions and their results will be presented and discussed in the following sections of this article.

Regarding the types of organizations represented by the participants, approximately 27% were affiliated with city and/or municipal construction departments. Participants from universities and research institutes constituted over 25%, while the third largest group, comprising 24%, was from modular construction companies. A smaller proportion of participants were associated with design offices, business entities, and social housing associations, among others.

Regarding the geographical distribution of participants, North America accounted for approximately 35%, followed by South America at nearly 30%, and Europe at approximately 27%. Additional participants originated from Africa, Asia, the Middle East, Australia, New Zealand, and Canada.

In response to the inquiry, "How would you define the concept of a Circular City in the context of modular construction technologies?", approximately 39% of respondents identified it as a city employing advanced recycling technologies to manage construction and demolition waste. Over one-quarter of the participants described it as a city that integrates Modular Integrated Construction (MIC) and other innovative technologies to enhance resource efficiency and minimize waste. Additionally, more than 20% characterized it as a city that adopts sustainable construction practices, such as energy-efficient designs and the use of renewable materials. Respondents also highlighted that the approach to construction in these cities focuses on maximizing the reuse and repurposing of building materials, actively working to minimize environmental impact and foster resource-efficient urban development.

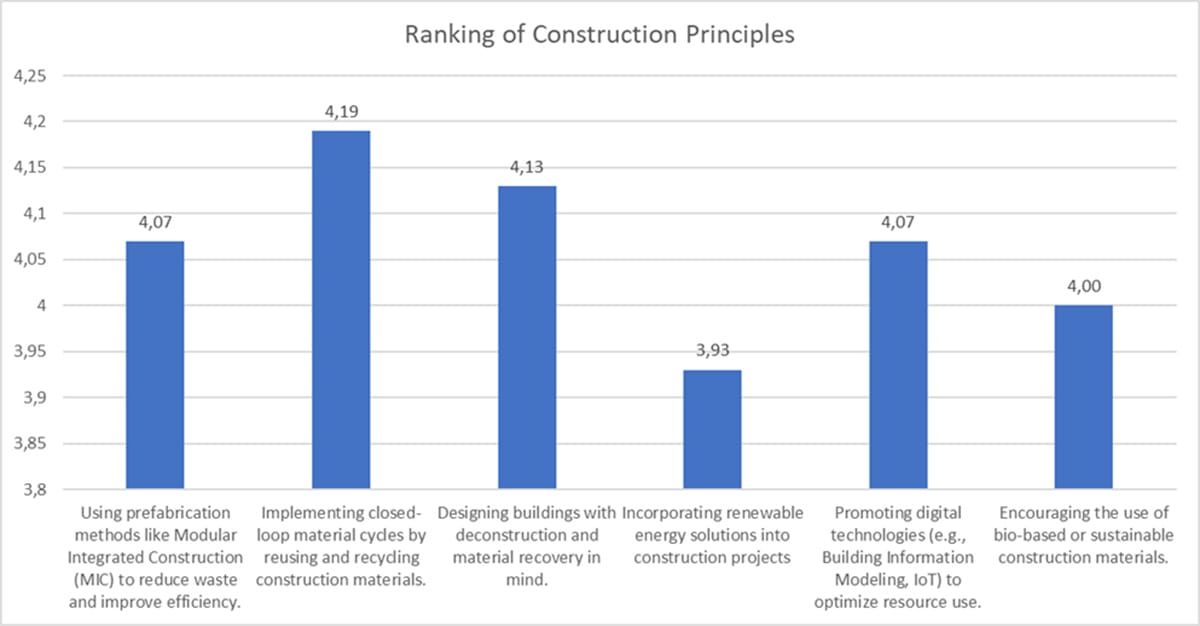

The subsequent question, following the one mentioned above, was: "Based on your understanding of a Circular City, how would you prioritize the following construction principles to achieve the target, using a scale from 1 (strongly disagree) to 5 (strongly agree)?" The responses were assessed in the diagram below.

Diagram 1: Ranking of Construction Principles

The participants assigned the highest ranking, with a score of 4.19, to the response "Implementing closed-loop material cycles by reusing and recycling construction materials." Conversely, the response "Incorporating renewable energy solutions into construction projects" received the lowest ranking, with a score of 3.93.

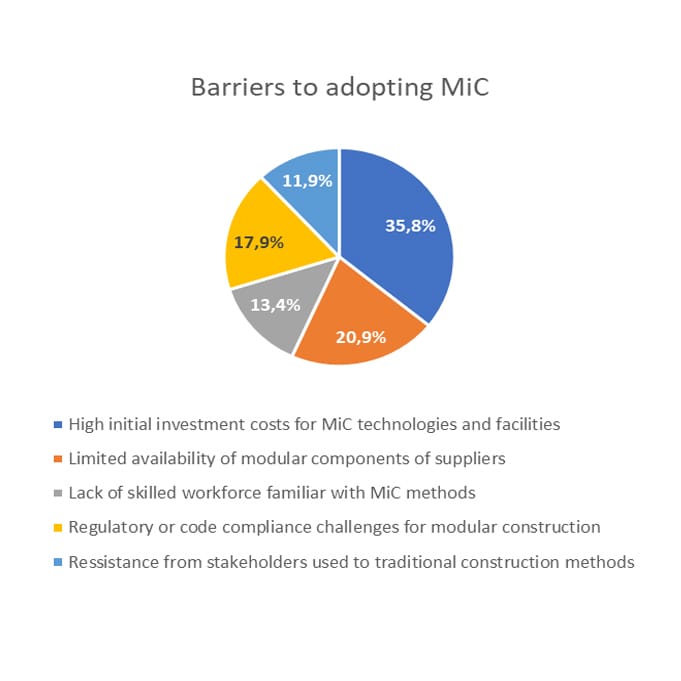

One notable topic highlighted in the survey pertains to the identification of barriers and benefits to the adoption of MiC Technologies. Participants were asked to identify the primary obstacles to implementing MiC within Circular City Initiatives in their respective organizations. The results indicate that over 35% of respondents identified high initial investment costs for MiC technologies and facilities as a significant barrier to implementation. Additionally, more than 20% of participants cited the limited availability of modular components or suppliers as a challenge. The third largest group, comprising nearly 18% of respondents, identified regulatory or code compliance challenges associated with modular construction as a barrier. The complete results are presented in Figure 1.

Figure 1: Barriers to adopting MiC

Figure 2: Benefits to adopting MiC

Conversely, the benefits of MiC have been examined. Foremost, with 24.4%, is the reduction in construction costs compared to traditional construction methods. This does not contradict the previously mentioned high investment costs as a barrier. Instead, they represent two temporal aspects of the same technology: substantial initial investments (including the acquisition of production equipment, planning, development, and process conversions, which are often necessary with MiC technologies) are counterbalanced by long-term savings in construction costs. Both points reflect a realistic and nuanced understanding of MiC technologies in construction practice. The reduction in construction time ranked second at 20.9%. Additionally, a significant reduction in construction waste was reported by 16.4% of the participants. You can find the complete results for this question in Figure 2.

In this survey, participants were also solicited for recommendations to expedite the adoption of Modular Integrated Construction (MiC) within Circular Cities. The question posed was, "What strategies can enhance the adoption of MiC within Circular City Initiatives?" Respondents could rank seven sub-answers on a scale from 1 (strongly disagree) to 5 (strongly agree). The results indicated that participants predominantly believed Circular Cities drive innovation in the implementation of MiC, with an average score of 4.25. Additionally, there was a consensus on the necessity to develop and implement standardized regulations for MiC across the region, also averaging 4.25. In contrast, fostering collaboration between MiC manufacturers, designers, and construction companies received a lower average score of 3.93. The complete results for these seven sub question are shown in Diagram 2.

Diagram 2: Recommendations for Accelerating MiC Adoption in Circular Cities

Conclusion

The survey findings highlight the significant potential of Modular integrated Construction (MiC) in advancing the development of circular cities. By reducing costs, accelerating construction timelines, and minimizing waste generation, MiC offers a promising approach to sustainable urban development. This method of construction aligns well with circular economy principles, as it allows for more efficient use of resources, easier disassembly and reuse of building components, and overall reduced environmental impact throughout the lifecycle of buildings.

However, the widespread adoption of MiC faces several challenges that need to be addressed. High initial investments pose a significant barrier, potentially deterring developers and construction companies from embracing this innovative approach. Additionally, complex regulatory requirements and varying building codes across different regions can complicate the implementation of MiC projects. To overcome these hurdles, the survey suggests the development of regional standards that can streamline the approval and implementation processes for MiC. Furthermore, targeted innovation promotion initiatives are recommended to encourage research, development, and adoption of MiC technologies. These measures could include financial incentives, public-private partnerships, and educational programs to build expertise in the construction industry and foster a supportive ecosystem for MiC implementation in circular cities.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.