The Missing Link in Modular: Developer Relevance & Messaging

RJ Mahadev is the CEO/Co-Founder at RaaP Builders.

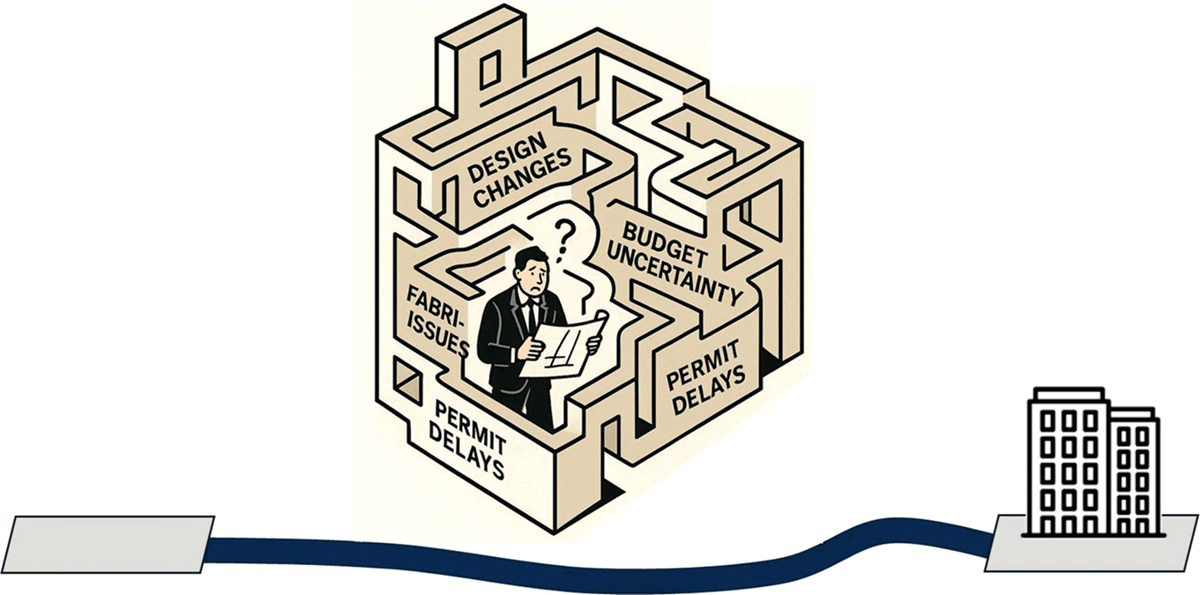

1. Developer Frustration

Many affordable housing developers have looked at modular. Maybe even tried it. And it’s complicated.

Design revisions. Pricing black holes. Fabricators who couldn’t deliver what was promised. Everyone said modular would save time and money. Instead, it felt like a gamble developers couldn’t control.

And here’s the truth: It not anybody’s fault.

The problem isn’t the fabricator, architect or GC. It’s everything that happens between them. From design through pricing, permitting, and fabrication, developers are left to connect the dots between systems that don’t work together.

That’s where modular breaks down. And that’s where a Rooms as a Product approach changes the game.

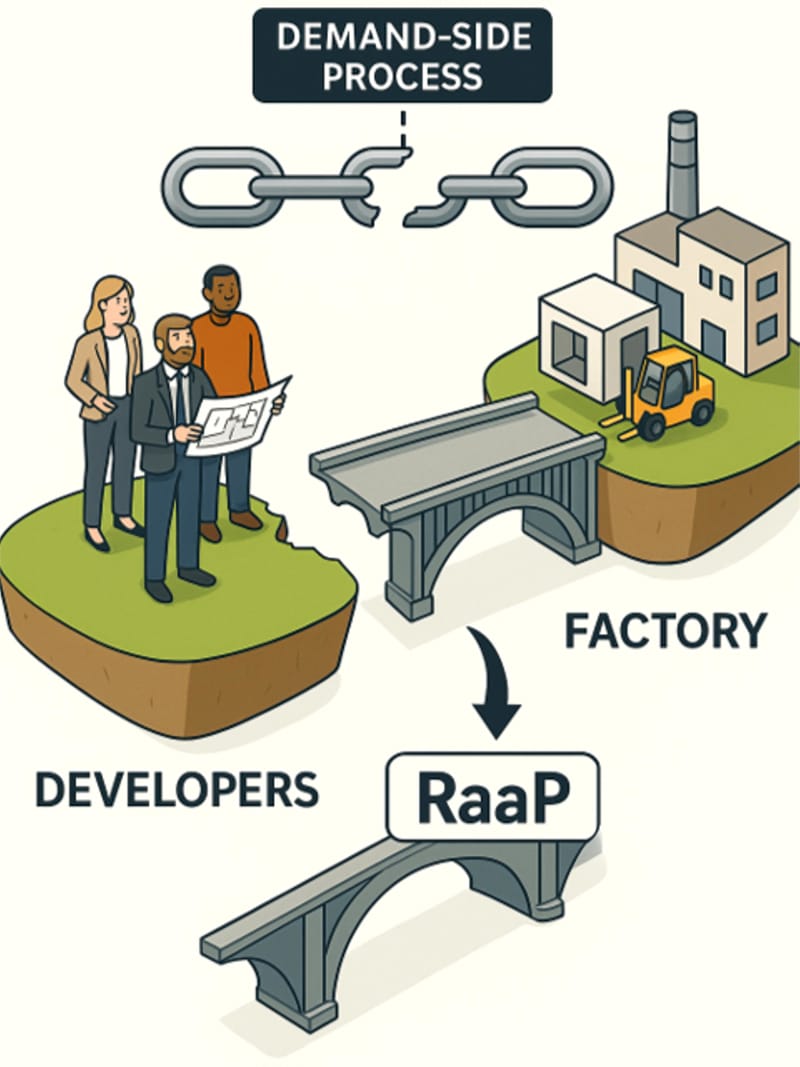

2. The Missing Piece

The modular industry has been solving a supply-side problem: how to build better in a factory. How to design a superior wall panel system that can be manufactured more effectively. But what no one’s addressed is the developer-side problem: how to plan, price, design, deliver AND communicate a modular project that offers speed and certainty to developers. Not boxes, A believable process that enables modular for developers.

That means:

- Getting developers to a confident “yes” or “no” on modular in days, not months.

- Aligning modular design, pricing, and delivery before anyone goes into drawings.

- De-risking the choice of fabricators and ensuring accountability.

- Enabling modular-ready permitting and documentation from day one.

Think of it like this: Modular without and end-end process is like a factory on an isolated island. Lots of potential but disconnected from everything that matters.

This is the operating system modular has been missing!

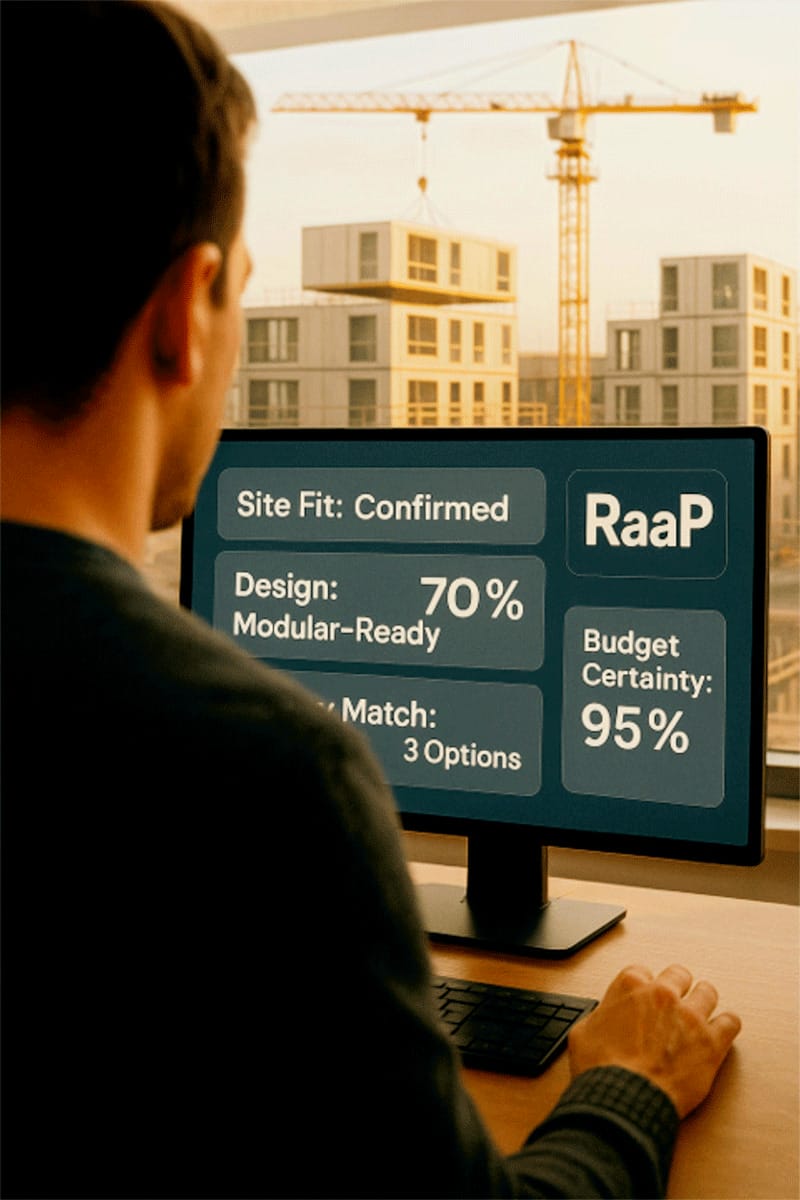

3. The RaaP Productized Approach

What developers need is a full-stack modular delivery platform designed for them. Four core modules that plug directly into their process:

A. ModularFeasibility (No cost go/no go): “Is modular construction my best option?”

A rapid turn-around (hours/days not weeks/months) to evaluate modular fit, site constraints, and potential project scope prior to underwriting. This should take the parcel map and planning goals and return:

- Massing and unit yield based on real modular dimensions.

- Estimated pricing band from recent modular benchmarks.

- Factory fit assessment.

- Potential zoning, logistics and other issues unique to modular.

- Go/No Go for modular with quantified metrics.

B. SmartStart (Predevelopment Package): “Design + budget for the modular project”. For a low fixed fee, the foundation for developers to plan their modular project:

- Modular-optimized schematic design and stacking plans.

- Detailed budget breakdown (soft + hard costs).

- Coordinated fabricator strategy.

- Documents to speed up entitlement and lower costs.

C. FabAssure (Fabricator Evaluation + Execution) “Selecting & managing the fabricator”. Vet and negotiate with the top fabricators for the project type, geography, and budget.

- Shortlist with pros/cons and scorecard.

- Pricing and capacity confirmation.

- Negotiation support and scope alignment.

- Delivery management & reports.

D. EasyDesign (CD + Permitting) “Design collaboration across the architect, fabricator & sub-contractors”. Modular-first construction drawings to ease local and state permit and support factory production.

- Modular design coordination (MEP, structural, finishes).

- State permit set submission documents.

- Local AHJ permit set coordination.

- Connect factory shop drawings to permit sets.

Several NYC pilot projects have demonstrated modular construction’s potential while also revealing key implementation challenges:

4. The Proof

Case Snapshot: Hosteling International Santa Monica

- 46-unit modular hostel project.

- Constrained site conditions, tight budget & delivery requirements. Ensure high quality & reduce delivery risks.

- RaaP delivered a ModularFeasibility study in 6 days.

- SmartStart wrapped in 5 weeks with fully priced, modular coordinated design.

- Held GMP to fit within budget.

- “RaaP brought structure and clarity to the complex modular process, which makes a big difference.”

Case Snapshot: EAH Housing, Greenfield Commons

- 200 income qualified apartments utilizing volumetric modular construction.

- Developer needed a design optimized for modular fabrication and deep collaboration between the Architect, the fabricator & the GC.

- Leverage Design + Technology + Fabrication to help manage RFIs & submittals.

- Design productization to drive continued design and process improvements.

- “Modular works when the process works”.

Case Snapshot: Nationwide Extended Stay program for a major hospitality brand

- Speed up the construction of new extended stay projects (Studios + 1 bedroom). Improve developer profitability.

- Benchmark hard construction costs for projects nationwide. Compare modular construction costs and time to site built. Develop modular-optimized designs and mitigate project risks.

- Price Predictability: Hard construction estimates with 95%+ accuracy based on standardized assemblies.

- Design Optimization: Standardized designs that optimize factory throughput & savings.

- Modular Ecosystem: Curated ecosystem of Modular companies (GCs, fabs, setting, transport, consultants, etc.) that can complete the project.

- “RaaP is a must-have tool for any developer interested in saving time & money with modular projects”.

5. Why This Matters Now

Everyone wants to solve the housing crisis. But few are solving this in a scalable way for developers. RaaP makes modular plug-and-play. Instead of hunting for modular experts, coordinating between siloed teams, or crossing their fingers at pricing time, developers get one clear, integrated path from site to set.

We don’t need another white paper. We need a productized path to faster, more reliable delivery — one that fits into the way construction works. And here’s the kicker: It doesn’t require developers to go all-in on modular! RaaP lets developers explore, evaluate, and execute with confidence. No guesswork, no sunk cost, no dead ends.

6. Call To Action: Take The First Step

If you’ve ever said:

- “Modular could work for this, but I can’t price it early.”

- “My team doesn’t know how to design for modular.”

- “I don’t know who to trust on the factory side.”

RaaP is built for you.

Send us your site. We’ll run a free ModularFeasibility study and show you what’s possible.

Because modular isn’t the future of housing. It’s a tool we need right now — and with the right approach, it finally works.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.