Sam Taylor: Leading the (Modular) Design of Tomorrow

Samantha Taylor’s big dream is to work with her mom to design, engineer and build modular home communities for seniors to downsize to in Newfoundland.

It’s a dream that might take some time to fulfill, but it’s a great example of Samantha’s approach to modular building and life in general.

A natural problem solver, dedicated team player, and voracious learner, her seemingly meteoric rise within Steenhof Building Services Group is rooted in a willingness to try, fail, learn, and keep trying and the idea that nearly everything is possible.

Curiosity and A Willingness to Get Her Hands Dirty

Most architecture students spend summers interning in design offices, preparing for their future roles by immersing themselves in them.

Taylor decided to do something a little different. Or, as she puts it, “I knew I was going to be sitting behind a desk for the rest of my life, so I wanted to do something different. To really learn about the construction industry.”

This is why, when her peers were donning suits and heading to offices, Taylor spent her university breaks working as a carpenter’s helper, observing the industry from the other end of the spectrum.

An Accidental Career

Most people have a clear idea of what they want to do with their professional life, and Taylor thought she would have a similar experience.

A native of Newfoundland and Labrador, she completed an architectural technology degree and then, like many young people, took a gap year to figure things out.

Taylor was sure she’d eventually follow the traditional path, at some point finding her way into an architectural firm, designing beautiful custom homes.

But a trip to Ontario with a friend changed everything. It’s there that she discovered a job opportunity at Steenhof, took the plunge, and joined the company as a designer.

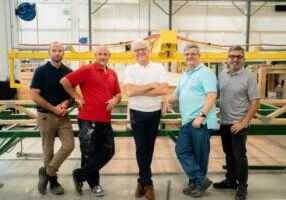

Sam Taylor, vice president of design at Steenhof Building Services Group.

Good Leaders Create Good Leaders

Having a great mentor often makes all the difference, particularly in the construction world, and that’s exactly what Jack Steenhof and many of his senior staff were to Taylor and other new hires.

Their willingness to share knowledge, answer questions, and allow junior staff members like Samatha to try things outside of their comfort zone meant that there was not only room to grow but encouragement to take on new challenges and think outside of the box.

In Taylor’s case, embracing those opportunities led to promotions. First, to the leadership of a team of one. Then to managing the five-person modular design team, and finally, to her current role as VP of design.

Most importantly, Samantha Taylor is leaving the door open and the ladder extended in just the same way.

“Working with my team, training new hires, and allowing other people to be the smartest person in the room is a huge part of the job,” says Taylor.

A Holistic Approach to Modular

As a design and engineering company, Steenhof Building Services Group tackles a variety of projects in Ontario, Canada, and the USA. But what many people don’t realize is that Steenhof also offers every other service necessary to facilitate a successful modular build.

The company just completed a round of hiring, expanding their MEP and other teams, and they offer everything from code review to help with certifications and even writing quality assurance documents.

They’re already heavily involved with Canadian modular manufacturers, and they’re working with international companies looking to bring more modular options to the country.

“With modern technology and the way we’ve all embraced things like BIM, file sharing and video conferencing since COVID, it’s easy to collaborate with companies in Austria, or Singapore, or anywhere else in the world.”

Steenhof’s goal, and one that Taylor is particularly passionate about, is to make modular buildings accessible to everyone, and they’re pursuing every avenue to achieve it.

What's Next

With so many achievements already under her belt and the backing of a company like Steenhof, it’s clear that Samantha will continue to grow into one of the driving forces in modular building in Canada.

For the company, the modular building world just keeps expanding, whether it’s custom cottages in northern Ontario and beyond, modular buildings for remote and hard-to-reach areas in the territories, or assisting in bringing new manufacturers to market.

They’re even involved in the trend of relocating modular buildings and, really, just about anything else you can imagine in the world of modular.

So, while Sam Taylor might be a little too busy to create desirable modular home villages for seniors in Newfoundland right now, it’s almost certain that she’ll check it off her extensive to-do list at some point.

About the Author: Tamara Aspeling is a published author and freelance writer who specializes in construction and writes for print and web. She’s also a trained estimator and project manager with over 20 years of industry experience. You can reach her at www.theconstructionwriter.ca or words@theconstructionwriter.ca.

More from Modular Advantage

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.

LifeArk: Disaster-Resilient Housing from Recycled Plastic and 100-year-old Technology

Wee compares LifeArk’s housing units to Yeti coolers, as they are built similarly. Each component takes 15 to 20 minutes to manufacture, has an R-value of 40, and includes molded slots and chases for wiring, plumbing, fire sprinklers, and other utilities.

Building the Future of Modular Edge Infrastructure

The edge data center market is expanding rapidly, driven by the surge in AI workloads, IoT adoption, and the need for localized compute power. In these environments, sustainability, scalability, and reliability are non-negotiable. Cooling is among the most complex challenges for operators—and one of the most decisive factors in long-term success.

Accelerating Light-Gauge Steel Construction: A Semi-Automated Digital Workflow for Off-Site Projects

For construction professionals, the message is clear. By adopting semi-automation and digitalization, companies can deliver projects faster, more accurately, and more profitably, while also building stronger collaboration across teams. The approach is not about replacing people with machines, but about empowering people with better tools and processes.

Why Modular Data Centers Are Gaining Momentum

Artificial intelligence, high-performance computing, and edge applications push the limits of traditional “stick-built” data centers. They take years build, often struggle with high density workloads, and aren’t optimized for deployments near end users. Modular data center platforms are purpose-built to address these challenges, offering flexibility and scalability to adapt to evolving technologies, while opening new opportunities for the modular construction industry.

Supply Chain Innovation in Action: 5 Habits Every Modular Leader Should Practice

By applying these principles to supply chain practices — collaborative planning, strategic procurement, scenario modeling, digital tools, and transparent forecasting — construction leaders can build value chains that are not just efficient and agile, but truly innovative.

Exploring the Role of Modular Integrated Construction (MiC) in Advancing Circular City Principles – A Survey of Stakeholder Perspectives

The survey findings highlight the significant potential of Modular integrated Construction (MiC) in advancing the development of circular cities. By reducing costs, accelerating construction timelines, and minimizing waste generation, MiC offers a promising approach to sustainable urban development.

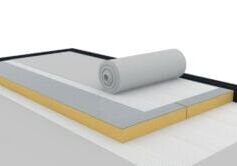

The Use of MS POLYMER™-Based Sealants and Adhesives in Modular Building

These products combine flexibility and elastic recovery with excellent adhesion to different substrates and have already shown their usefulness in traditional construction. Now it’s time for them to be put to use in the modular construction industry.