Modular and Off-Site Construction: Risk Questions, Scenarios, and Suggestions

B. Daniel Seltzer, CPCU, is a principal of Seubert & Associates, Inc.

Thanks to our friends at MODLOGIQ, we are proud to announce ourselves as a new member of the Modular Building Institute. Thank you for the warm welcome at World of Modular in Las Vegas last April. We hope to establish long-term, trusting relationships with MBI members, and we look forward to participating in the upcoming expos and the World of Modular in 2024.

We offer the following thoughts as an introduction to Seubert & Associates, Inc.

Question #1: Is your insurance company an adversary or a partner?

My 42 years in the business indicates neither is the correct answer! Carriers are experts at assuming specified, fortuitous, quantifiable risk with conditional promises to pay IF various distinct facts occur, all in exchange for your premium dollars. Who has the advantage on this playing field?

Question #2: Who composes the fine print of the insurance contract, and for the benefit of whom?

The multi-billion-dollar carrier and reinsurers standing behind the contract, or the MBI member reading this article? Who would you bet on, and what tools are at your disposal to improve the rules of the game? Who to turn to, and when?

Question #3: Are you prepared?

When considering risk exposure in your industry, many traditional construction risks are mitigated. A few examples of reduced risk include theft of materials, bodily injury, and enhanced quality. Any new risks? Can you identify exposures created by modular construction? There are a handful. Have you prepared?

Building upon these questions, I invite you to consider the following scenarios.

Scenario #1

To level the playing field, is the best choice of insurance agent one who first obtains copies of your policies, then floods the market with e-mails to hopefully find the lowest rate from the hot underwriter on that given day? Or are chances enhanced by working with a trained risk management professional serving as your broker, who is fiercely independent and understands your exposures to loss at least as well as yourself?

Scenario #2

We are currently experiencing the “hardest market” in over 350 years; insurance rates have increased 19 quarters in a row. This has never happened before, ever! Do you understand why? If you know the dynamics, including your risk profile, you can reduce your Total Cost of Risk.

With the preceding insights in mind, let’s explore suggestions to effectively navigate the complexities of the insurance and risk transfer landscape.

Suggestion #1

Although the “modular” and “off-site” construction business is not new, it is a relative newcomer, and not as mature as the insurance industry. Insurers are conservative by nature and utilize historical data to promulgate rates. When actuaries determine data is not statistically credible, what do you believe is the result? Exactly, lack of competition and unattractive pricing! I believe MBI and its members can do something about this phenomenon.

Shall we discuss?

Suggestion #2

Businesses are glued together by contracts. Try improving your risk profile and how you present yourself to underwriters. This will yield impressive results compared to obtaining bids from hungry insurance salespeople. Arrange for new eyes to review your important contracts and implement best practice processes.

Suggestion #3

Encourage your insurance agent/broker to include you in the negotiating process with underwriters, and I mean directly. Sure, the best risk management professionals can “pitch” your account from an exposure, coverage, and strategic perspective, but no one will have more interest and knowledge of your business operations than yourself. If “prepped” correctly by your broker, you would bring the “special sauce,” which is missing in 95% of insurance submissions in the marketplace. Do not wait for insurers to lower rates. It will not happen until market forces create competition. Currently, reinsurance capacity has been seriously depleted, which restricts competition. Take control!

Real Life Example

Why the insurance advocate you entrust with protecting your assets and shielding your organization from liability is essential to your survival as an entrepreneur.

Most insurance brokers focus on where the commission dollars come from, and how to earn more. The best brokers take their work seriously and are fulfilled when they know their client is correctly insured.

Greater than 65% of the commission dollars for MBI manufacturers and contractors are within General Liability, Workers’ Compensation, and Excess Liability insurance policies – this is important coverage for sure.

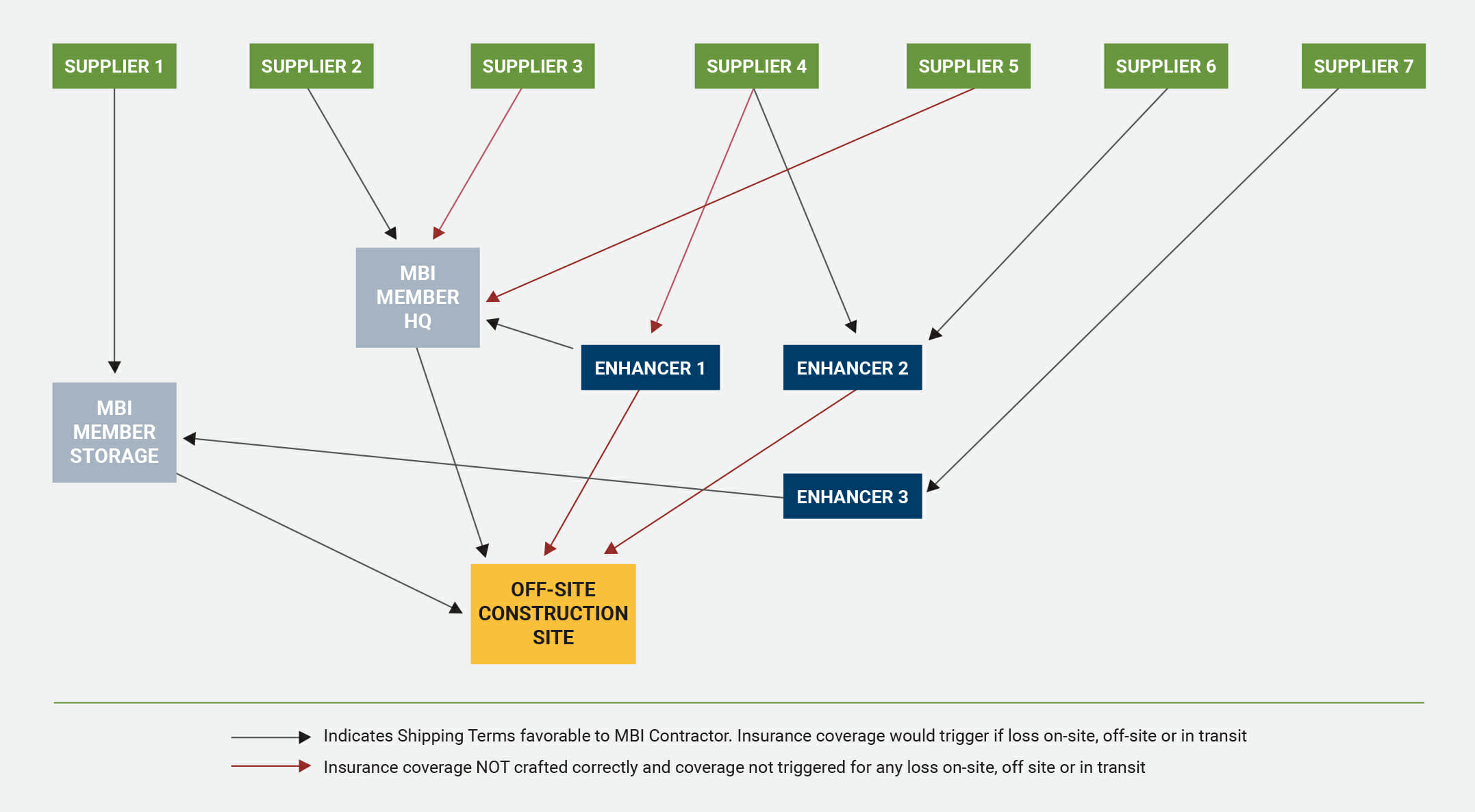

May we talk about Property and Inland Marine coverage for a moment? It is rare to meet an insurance professional who, WITH REAL PURPOSE, asks the correct questions to assure their client is situated properly. I am happy to discuss why if you wish. For now, ask yourself two simple questions. First, does your insurance “person” truly understand when, why, how, and to what extent your insurable interest in property is created and when it ceases? See the graphic below which supported a new MBI client’s suspicion of their prior insurance agent not paying attention.

Second, once these questions are answered, does your broker understand and then suggest cost-effective solutions?

Considering the unique nature of modular projects, MBI members need to carefully address surety considerations to ensure successful outcomes.

1. Surety Selection

Selecting a quality surety professional is of utmost importance. When researching a firm, consider their years of experience and amount of bonds written, current

relationships with underwriters, and the memberships they hold to various professional associations, as well as their overall knowledge of your unique industry. By partnering with a reputable consultant, you can ensure reliable performance that maximizes your bonding capacity.

2. Design Elements

Failures during the design stage will trigger delays and increase costs. If the contractor is responsible for designing the project, delays will cause margins to shrink, eat into working capital, and impact the balance sheet, which is integral to surety underwriting decisions.

3. Supplier Risk

Contractor must know:

- Can the manufacturer meet the timeline?

- What happens if the manufacturer cannot meet the schedule or ceases business operations?

- Can the contractor replace the manufacturer, or will the contractor need to return to the design/engineering stage with a new manufacturer?

4. Transportation

Increased costs result from shipping delays and damages, which can trigger liquidated damages or actual damages clauses. Related to damage delay clauses, contract language must be reviewed. Surety underwriters want to make sure the contractor can meet the timelines.

5. Construction Defects

Modular build quality can suffer with the wrong employees or misused automation equipment. Contractors should ensure the right labor is in place, understand local legislation, and always keep quality at the forefront. To help with the underwriting process, modular contractors should be able to answer questions regarding their experience with the modular building supplier and the process to prequalify the supplier.

6. State and Local Building Codes

Modular contractors should be aware of varying state and local building codes. Surety underwriters ensure contractors are knowledgeable about these codes. If a contractor is moving into a new territory, surety underwriters will remind contractors that building code knowledge is key.

7. Prevailing Wage Issues

In some states, contractors are responsible for unpaid prevailing wages and unpaid penalties, even if a subcontractor or supplier completed the work. The contractor must assess its contractual obligation to determine if a modular builder will fall under a subcontractor, manufacturer, or supplier classification.

8. Labor

The difference in complexity between a single-story modular building and a high-rise or mixed-use development modular building can be exponential. Construction labor availability continues to be a major challenge, and the lack of experience assembling these buildings can make it more difficult for contractors looking to enter the modular building market. Surety underwriters will ensure the right labor is in place to complete the project within its parameters.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.