Poland's iQ Module is Expanding What's Possible with Modular Construction

Located in Gdynia, Poland, the InfoBox—built by iQ Module— is Gdynia InfoBox is a center for information about urban developments and projects being implemented in the city. It also serves as a tourist attraction and features a 22-meter lookout tower.

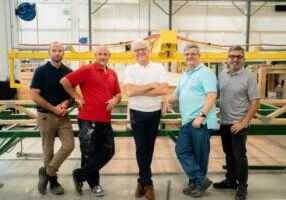

The modular industry is expanding globally with considerable growth in Europe. iQ Module, headquartered in Gdansk, Poland, has contributed to that industry growth. MBI caught up with iQ Module co-founder Krzysztof Droszcz and talked to him about what iQ Module is doing and how the modular industry is growing in Europe.

MBI: What notable projects are you currently/have you recently worked on that you’d like to share?

KD: There are a few but the most significant has been InfoBox in Gdynia, Poland. This building was raised on steel frame modules using mostly glass structure facades as walls. The building itself is a city tourist Info Center with conference space, two restaurants, a few modular galleries, and a viewing tower that overlooks the city and the sea. It’s situated in the Gdynia city center and has become an iconic, well-known building..

We were the designers as well as the builders of that magnificent structure. The building itself got a few national and international awards and distinctions.

Another notable project is a single house in Sopot, Poland. It received an award for the best project in Sopot in 2019. The house represents simplicity in architecture. The whole roof and facade are made from fiber cement boards decorated with subtle wood finishing, making that project interesting to see and touch.

MBI: How has COVID-19 affected your business this year? How have you had to adapt?

KD: That’s a question we are still answering. Everything has changed and we’ve had to adapt to the new order of the world. We have recently been preparing iQ for global market expansion and we have been concentrating on the US, UK, and Germany especially. We have developed some paths to the hotel and residential market. After the COVID-19 lockdown, we were forced to diversify our production targets and modify our products.

We have also been involved in creating quarantine and isolation units. We have to produce to keep the company rolling but we’re also trying to get involved in stopping the pandemic as that’s in all of our interest to take it down. It’s a hard time but we try to use it most effectively.

MBI: What’s been the biggest benefit of being an MBI member?

We were looking for a wider view on the modular market and possibilities. Entering the US market as a member of MBI gives us much more contact with fellow modular producers, designers, and specialists so we can get involved in the global modular market. Another great thing about membership is getting to meet industry pioneers, experienced investors, and architects with whom we are happy to work. As we expand outside of Europe, we’re seeking to be a part of a global modular family. Being an MBI member is proving to be a great value for us.

MBI: Have you noticed the industry change since you became part of it? How so?

KD: Since the COVID-19 pandemic hit, the changes have been significant. We’ve seen how members of MBI have been developing new ideas to keep the industry well. The situation we are all affected by is also a time of opportunity. The trick is to use wisdom and convince more stakeholders to trust modular technology.

MBI: How would you describe the modular construction industry in Europe overall?

KD: There is tremendous potential for modular construction in Europe. On the one hand, there is a lot of tradition on our continent, but on the other hand, there is a huge need for new technologies.

For example, one of the most interesting markets we have experienced is in Scandinavia. Our wood modules fit in that environment perfectly and it’s eco-friendly. Norway and Sweden have a long history of building modules and wood structure buildings. That market is still developing. Steel structure modules are not as popular yet but they’re almost a necessity to use for higher structures. The market is beginning to realize that modular technology is a solution yet there is still a lot to do to encourage clients to think modular.

More from Modular Advantage

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.

LifeArk: Disaster-Resilient Housing from Recycled Plastic and 100-year-old Technology

Wee compares LifeArk’s housing units to Yeti coolers, as they are built similarly. Each component takes 15 to 20 minutes to manufacture, has an R-value of 40, and includes molded slots and chases for wiring, plumbing, fire sprinklers, and other utilities.

Building the Future of Modular Edge Infrastructure

The edge data center market is expanding rapidly, driven by the surge in AI workloads, IoT adoption, and the need for localized compute power. In these environments, sustainability, scalability, and reliability are non-negotiable. Cooling is among the most complex challenges for operators—and one of the most decisive factors in long-term success.

Accelerating Light-Gauge Steel Construction: A Semi-Automated Digital Workflow for Off-Site Projects

For construction professionals, the message is clear. By adopting semi-automation and digitalization, companies can deliver projects faster, more accurately, and more profitably, while also building stronger collaboration across teams. The approach is not about replacing people with machines, but about empowering people with better tools and processes.

Why Modular Data Centers Are Gaining Momentum

Artificial intelligence, high-performance computing, and edge applications push the limits of traditional “stick-built” data centers. They take years build, often struggle with high density workloads, and aren’t optimized for deployments near end users. Modular data center platforms are purpose-built to address these challenges, offering flexibility and scalability to adapt to evolving technologies, while opening new opportunities for the modular construction industry.

Supply Chain Innovation in Action: 5 Habits Every Modular Leader Should Practice

By applying these principles to supply chain practices — collaborative planning, strategic procurement, scenario modeling, digital tools, and transparent forecasting — construction leaders can build value chains that are not just efficient and agile, but truly innovative.

Exploring the Role of Modular Integrated Construction (MiC) in Advancing Circular City Principles – A Survey of Stakeholder Perspectives

The survey findings highlight the significant potential of Modular integrated Construction (MiC) in advancing the development of circular cities. By reducing costs, accelerating construction timelines, and minimizing waste generation, MiC offers a promising approach to sustainable urban development.

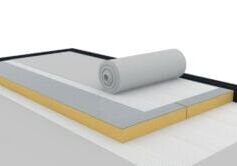

The Use of MS POLYMER™-Based Sealants and Adhesives in Modular Building

These products combine flexibility and elastic recovery with excellent adhesion to different substrates and have already shown their usefulness in traditional construction. Now it’s time for them to be put to use in the modular construction industry.