Building Smarter: A New Standard in Modular Construction Efficiency

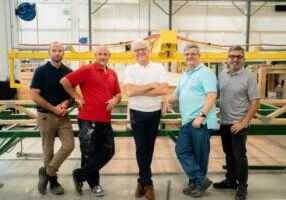

Stack Modular Structures Ltd. is a modular construction company based in Vancouver, British Columbia.

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

The Systemic Flaws of Traditional Construction

Daskalov notes that construction today still follows a linear, site-based model where each trade waits on the next and each contractor guards their own scope. He points out that few projects use standardized systems or build meaningfully from lessons learned. “Too often, every new build starts from zero,” Daskalov adds. “We repeat the same inefficiencies, the same risks.”

Instead of fixing root problems, the industry has leaned on contingencies and legal protections that add unnecessary cost without creating value. “We’ve added layers of risk management to replace process improvement,” he explains. “The result is unpredictable: delayed schedules, disputes, escalating budgets, and projects that no longer pencil.”

Modular Construction: The Solution in Plain Sight

The answer, Daskalov insists, lies not in marginal improvements to the old model but in the transition from site-built to off-site hybrid modular construction. More developers are now adopting steel-framed modules that are manufactured in controlled factories and then assembled on-site, treating mid-to-high-rise buildings as products rather than one-off projects.

This approach applies the same principles that transformed industries such as automotive and aerospace - standardization, quality control, and predictable output. Factories do not rely on ideal conditions; they create them, allowing construction to move faster and with less risk. That, Daskalov says, is the mindset the industry needs.

By moving most of the building process into a factory while foundations are prepared on-site, the advantages become clear: projects move faster, costs stay on track, waste is reduced, and fewer workers are needed on site. Materials are measured, processes are repeatable, costs are set earlier, and quality remains consistent from the first module to the last. Builders adopting this method routinely deliver projects up to 30% faster than average conventional construction.

Why Some Modular Projects Still Fall Short

Despite the promise of modular construction, Daskalov acknowledges that not every project achieves its expected efficiencies. He points out that many developments labeled “modular” are, in reality, conventional builds assembled off-site. Architects, too, often miss the mark by designing from the outside in instead of from the inside out - building the system first.

He further critiques the industry’s ingrained habits: “Developers and general contractors continue to treat modular companies as subcontractors or material suppliers, undermining the integrated process required for true manufacturing efficiency. These practices often lead to a cycle of strained redesigns, schedule drift, and cost overruns. The modular method isn’t at fault; the process is.”

Without genuine manufacturing discipline, he adds, efficiencies quickly disappear. Real modular success, he says, comes when every module is part of a well-designed, engineered, and repeatable system that delivers speed, quality, and certainty by design.

The STACK Modular Advantage

For Daskalov, there's a "smarter way to build!" and it hinges on a "fundamental change in mindset to involve the manufacturer early at the table from day one, to advise and support the design and delivery of steel-framed mid- high rise modular buildings towards a predictable budget and schedule”. This mindset ensures design decisions are guided by manufacturing logic, not adjusted for it later. Using advanced tools like BIM and Revit, Stack’s Preconstruction and Design teams coordinate structure, architecture, and MEPF systems within a single source of truth, resolving issues long before production begins.

The proven Stack’s modular system is flexible by design, engineered to adapt to varying site conditions, architectural requirements, and local building codes across regions. Modules can be customized in size, configuration, and finish while maintaining the efficiencies of repeatable production. This balance between precision and adaptability ensures developers meet local regulations and project-specific design goals without compromising schedule or cost certainty.

With design decisions locked to manufacturing logic, production proceeds under strict discipline. Each module carries a digital record linked to a unique Mod ID, capturing inspections, photos, approvals and closed corrective actions; accessible to stakeholders and auditors at any time.

Compliance is addressed in-factory, not improvised on site. Modules are approved by the California Department of Housing and Community Development (CA HCD) before ever reaching the site, keeping projects moving with confidence. When the modules arrive on site, they are craned into place and fit as planned - costs remain predictable, schedules hold, and the finished building reflects the precision of the process that created it. According to Daskalov, that’s what “building smarter with the certainty that only manufacturing can provide” truly means.

In an industry hungry for certainty, building smarter is the new standard.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.