Sealed for Success: The Role of Waterproofing in Modular Construction

Christoph Kotsch handles international business development for Gebrüder Jaeger GmbH.

Water is one of the biggest threats to any building, causing structural damage, mold growth, and costly repairs if not properly managed. Waterproofing is the first line of defense, ensuring durability and long-term performance. As construction methods evolve, so do waterproofing solutions – moving beyond traditional coatings to advanced, factory-ready systems.

In this article, we explore why waterproofing is essential, look at the latest innovations on the market, and how suppliers are adapting to meet the demands of modern, high-speed construction. A well-sealed structure isn’t just an option – it’s a necessity for quality, efficiency, and long-term success.

Water Leakages Can Silently Compromise Any Building

The consequences of waterproofing done poorly go beyond aesthetics. Damp conditions create the perfect environment for mold and mildew, which not only degrade building materials but also pose health risks to occupants. In steel or concrete structures, persistent moisture accelerates corrosion and reduces long-term stability. Wood elements can swell, rot, and lose their load-bearing capacity.

The challenge with water damage is that by the time it’s visible, it’s often too late for a simple fix. This makes proactive waterproofing critical. A well-designed waterproofing system prevents moisture from entering in the first place, protecting both the building and its users from hidden risks. Whether it’s a residential module, a commercial building, or an industrial facility, ensuring watertight construction is essential for long-lasting quality and performance.

When it comes to bathrooms, we are looking at the most water-exposed area in any building. Without proper sealing, moisture can seep into floors and walls, weakening materials and creating costly repair issues over time. Given the frequent use of water in showers, bathtubs, sinks, and toilets, a reliable waterproofing system ensures that moisture stays where it belongs – inside designated wet areas and away from the building structure. In modular construction, where bathroom pods are prefabricated and installed as complete units, high-quality, factory-applied waterproofing is key to ensuring long-term durability.

The Evolution of Waterproofing Solutions

Waterproofing solutions have come a long way from traditional bitumen membranes and tar coatings. Over the years, advancements in material science and construction technology have revolutionized the way buildings are protected from water damage. Early systems were labor-intensive and prone to application errors, but modern waterproofing products are designed for higher efficiency, durability, and ease of use.

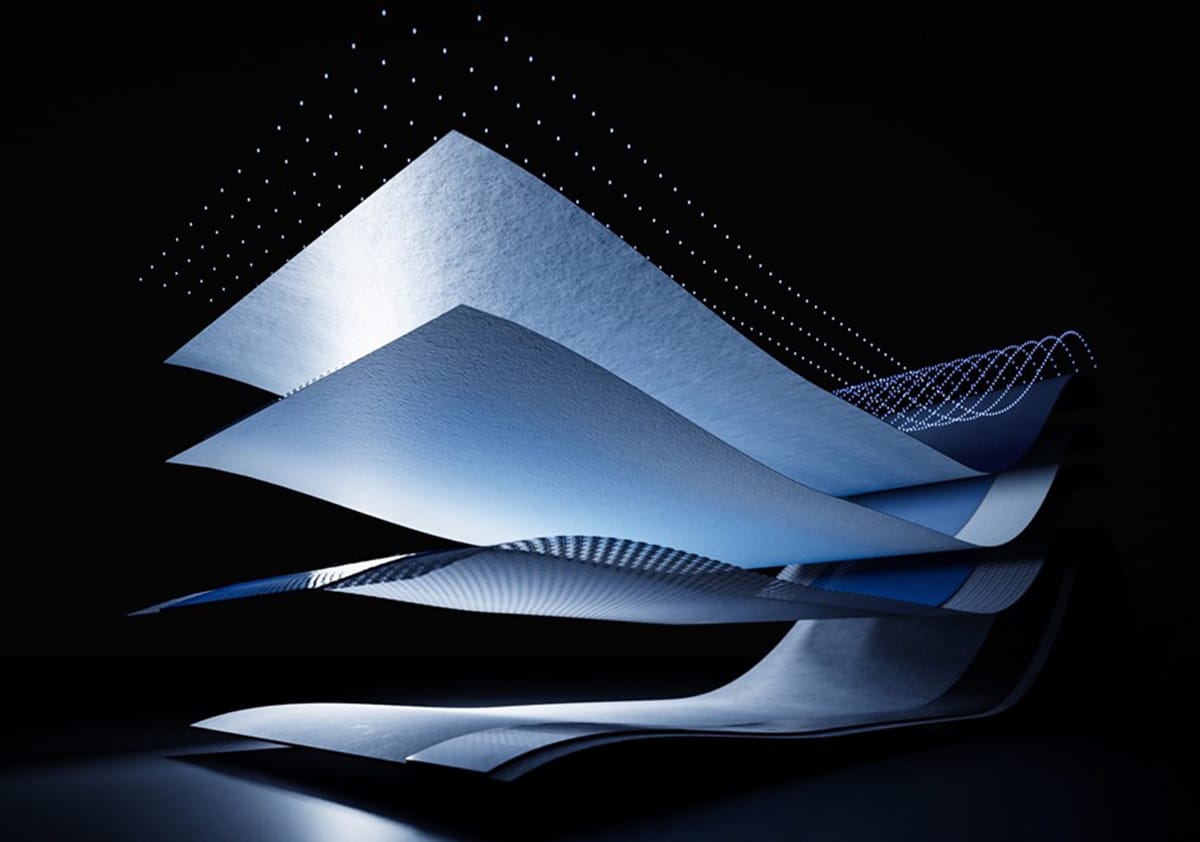

Today, advanced solutions include self-adhesive tapes, ready-made accessory pieces, such as corners and collars, as well as advanced sheet membranes that offer superior flexibility, adhesion, and resistance to water infiltration. These innovations are particularly beneficial in modular construction, where speed and precision are paramount. Factory-applied waterproofing ensures consistent quality, reducing the chances of failure during installation.

Additionally, environmentally friendly and sustainable options are emerging, with waterproofing systems that not only offer protection but also contribute to energy efficiency and building longevity. The shift from reactive repairs to proactive planning of integrated waterproofing reflects the growing understanding of how essential these systems are to a building’s overall performance and lifecycle.

Regional Differences across the World

The level of waterproofing used varies significantly from region to region, influenced by local climates and building codes. In countries with heavy rainfall or high humidity, such as the UK and Scandinavia, the standards for waterproofing tend to be more stringent, with intense test methods and certifications in place. In contrast, regions with drier climates, like parts of the Middle East, may focus more on insulation and heat protection, though waterproofing is still critical to address occasional storms and flooding. This regional variation necessitates a flexible approach, where suppliers must adapt their products to meet local conditions and regulations.

In the U.S., waterproofing practices vary significantly depending on regional climates and environmental conditions. In coastal areas like Florida or the Pacific Northwest, where heavy rainfall and humidity are common, waterproofing solutions focus on moisture resistance and prevention of water infiltration through walls, foundations, and roofs. In contrast, regions like the Southwest, with its arid climate, prioritize waterproofing systems that address extreme temperature fluctuations and thermal expansion, ensuring materials remain intact despite heat. The Midwest, with its seasonal freeze-thaw cycles, requires robust waterproofing systems to prevent water from entering through cracks that can expand and contract with changing temperatures. Meanwhile, in areas prone to flooding, like parts of Louisiana and the Gulf Coast, waterproofing systems are designed to withstand prolonged water exposure and protect against potential flooding. These regional differences highlight the importance of tailoring waterproofing solutions to local weather conditions, ensuring that each structure is properly protected against the unique environmental challenges of its location.

Modern Waterproofing Systems Save Time, Costs, and Resources

Today’s waterproofing systems are engineered for speed, efficiency, and multifunctionality – key advantages in both modular and traditional construction. Self-adhesive waterproofing systems with tapes, pre-formed corner pieces, and pipe collars streamline installation by reducing the use of chemicals. Applications are also faster and easier to do, even for non-professionals, all while keeping a clean workspace. In factory settings, where precision and repeatability are critical, these ready-to-use elements simplify the workflow and reduce the risk of errors.

Beyond ease of application, many modern products now combine multiple functions into a single solution. For example, waterproofing membranes with integrated decoupling layers help prevent cracks from substrate movement, while premium systems also include sound reduction properties – particularly valuable in multi-story residential buildings or hotel pods. These all-in-one solutions not only enhance performance but also reduce the need for additional layers, saving space, material costs, and installation time. By investing in advanced waterproofing systems, builders gain long-term reliability while optimizing production efficiency.

Manufacturers Must Keep Pace with Modern Construction

As modular construction continues to evolve at a rapid pace, suppliers of building materials must adapt to meet the demands of automated, factory-based production. Much like the transformation seen in the automotive industry, where component suppliers had to align with high-speed assembly lines, robotics, and precision engineering, building product manufacturers are now challenged to support similar levels of industrialization in the modular industry. This means developing solutions that integrate seamlessly into serial production processes while maintaining consistent quality and performance.

To stay relevant, suppliers must actively engage with modular manufacturers to understand their workflows, constraints, and technical requirements. Innovation is essential – often in close collaboration with customers – to create systems that not only meet performance standards but also simplify installation, reduce error rates, and support faster project delivery.

The future lies in highly standardized, yet customizable, solutions that can be tailored to different module designs and use cases. In addition to advanced products, forward-thinking suppliers are increasingly offering services such as on-site training, technical support, and prefabricated kits to ensure smooth production along the way. The shared goal is clear: greater efficiency, reliability, and scalability in a market with enormous potential for growth through serial construction.

A Watertight Structure is the Foundation of Every Building

At the core of every durable, high-performing building is a watertight structure. Effective waterproofing is not a single product or isolated measure; it is a coordinated system of solutions working together to protect against moisture intrusion. This system must be carefully tailored to the unique conditions of each project and the specific manufacturing processes involved. From membranes and sealing tapes to prefabricated corners and multifunctional layers, each component plays a critical role in safeguarding the structure.

In modular construction, where precision, speed, and repeatability are key, the waterproofing system must be seamlessly integrated into the production line. Only when solutions are adapted to the realities of industrial-scale manufacturing can they deliver both performance and efficiency. By designing waterproofing as a system – not just a product – and aligning it with production needs, manufacturers and suppliers can ensure long-term protection, reduce risk, and enable a streamlined, reliable building process from the first unit to the last.

Partnering for Reliable Waterproofing Solutions

At Gebrüder Jaeger, we understand the challenges and opportunities that come with modern construction, especially in the modular sector. Founded in 1924 in Wuppertal, Germany, we offer complete, factory-ready waterproofing systems designed specifically for the demands of serial production. With 13 international branches, we support construction projects around the world with reliable solutions and expert service.

Our portfolio includes waterproofing sheet membranes, sealing tapes, pre-formed corners and collars, as well as multifunctional solutions that combine waterproofing, decoupling, and even sound reduction in a single product. We also offer a fully self-adhesive system and have developed an eco-friendly product line to support sustainable building practices.

Every solution is developed with efficiency, reliability, and ease of application in mind. At our Technical Support Center, we conduct in-house testing in accordance with a wide range of regional standards and regulatory requirements, ensuring that our product systems are compliant and certified. We work closely with our customers to tailor solutions that fit their production processes and project requirements – because one-size-fits-all is no longer enough. If you’re looking for a waterproofing partner who speaks the language of modern construction, we’re ready to support your next project, wherever it takes you.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.