Design for Flow: The Overlooked Power of DfMA in Modular Construction

Unlocking higher throughput, lower costs, and fewer redesigns by aligning Lean production flow with design for manufacturing and assembly.

Daniel Small is the founder & CEO of Da Vinci Consulting.

The Missed Opportunity in Modular Design

Modular construction has reached an inflection point. As factories push to scale, many are realizing that traditional design approaches — even when optimized for assembly — often fall short of supporting true manufacturing flow. Despite growing awareness of Design for Manufacturing and Assembly (DfMA), too many designs are still conceived without consideration for takt time, station balance, or smooth product flow. The result? Bottlenecks, rework, and inconsistent throughput.

It doesn’t have to be this way. By aligning DfMA efforts with Lean production principles, modular manufacturers can achieve transformative gains in speed, efficiency, and quality. This article explores how to take DfMA beyond ease-of-assembly and turn it into a cornerstone of flow-based modular design.

What “Design for Flow” Really Means

In Lean thinking, “flow” refers to the smooth, uninterrupted movement of materials and work-in-progress through a value stream — ideally one piece at a time, paced to customer demand (takt time). Flow minimizes waste, reduces lead times, and enables predictable, scalable production.

In modular factories, flow is often disrupted by designs that, while architecturally sound, are operationally clunky. Examples include:

- Modules that require non-sequential assembly steps

- Complex MEP layouts that slow down installation

- Heavy assemblies needing special handling or off-line work

To design for flow, we must start with a clear understanding of how the module will be built, moved, and finished in a factory setting. That means designing around station rhythm, minimizing special handling, and simplifying task sequencing. Good flow also depends on predictability. When design enables consistent outcomes with fewer variables, every downstream process becomes smoother.

Designing for flow also means removing decisions from the floor. A well-designed product doesn’t force workers to interpret or improvise. It standardizes their actions, allowing them to focus on execution. In this way, flow isn’t just about speed — it’s about removing friction.

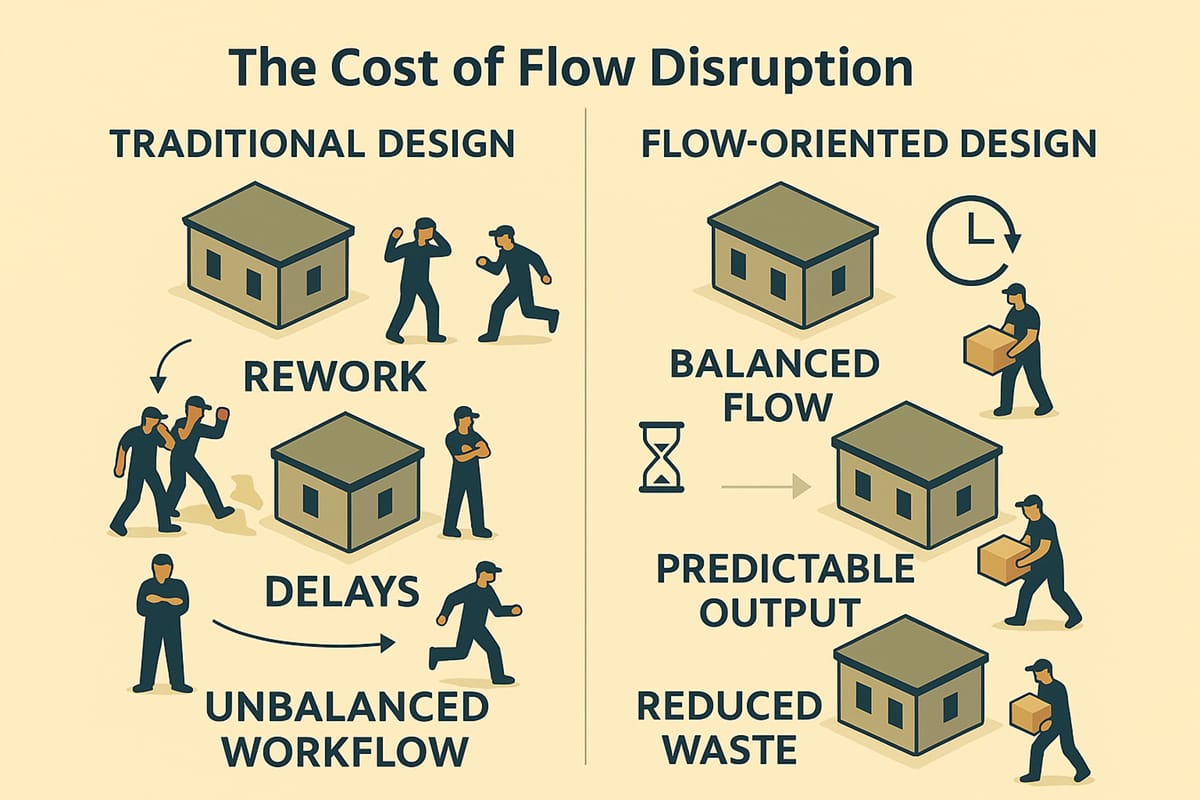

Traditional design causes chaos; flow-oriented design enables predictable, efficient modular production.

Done well, DfMA also enables flexible scalability. Once a system of flow-friendly, factory-fit modules is developed, it can be repeated, adapted, or mass-customized with minimal disruption. This is crucial for firms trying to meet rising demand without overextending resources.

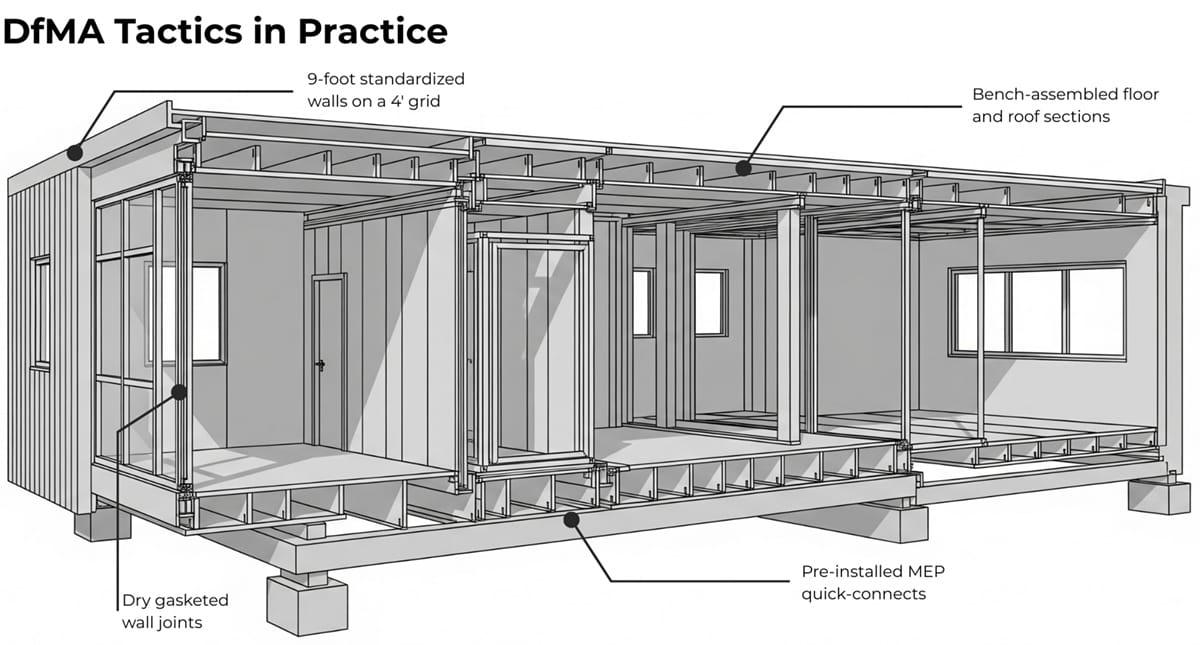

Key DfMA features that support modular flow — standardized grids, bench-built assemblies, and plug-and-play MEP.

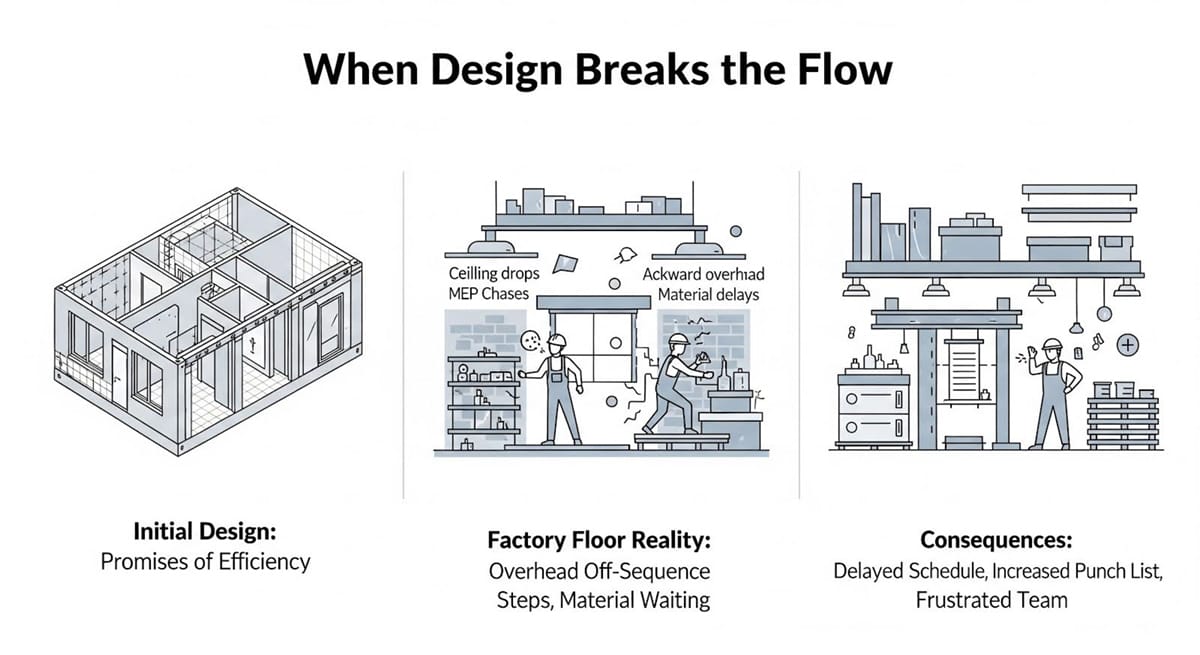

Case Snapshot: A Design That Broke the Flow

Imagine a modular factory launching a new line of multifamily units. The design includes intricate MEP pathways through tight chase walls, along with ceiling drops requiring a multi-step buildout. On paper, the modules look great. But on the floor, workers must deviate from their normal sequence, wait for parts, and perform overhead work that could have been done more efficiently at bench height.

Despite a beautiful end product, the factory experiences a 40% reduction in throughput and a sharp rise in punch list items. Why? The design was never mapped against the factory workflow. It prioritized final appearance over process simplicity.

This is not uncommon. Many modular projects are designed with site assembly or architectural elegance in mind, but without fully considering factory sequencing. The cost of this oversight is usually borne by production teams — who then improvise, slow down, or escalate quality issues. Many modular projects are designed with site assembly or architectural elegance in mind, but without fully considering factory sequencing. The cost of this oversight is usually borne by production teams — who then improvise, slow down, or escalate quality issues.

Poor alignment between design and production leads to delays, rework, and overwhelmed crews — while flow-based design avoids chaos.

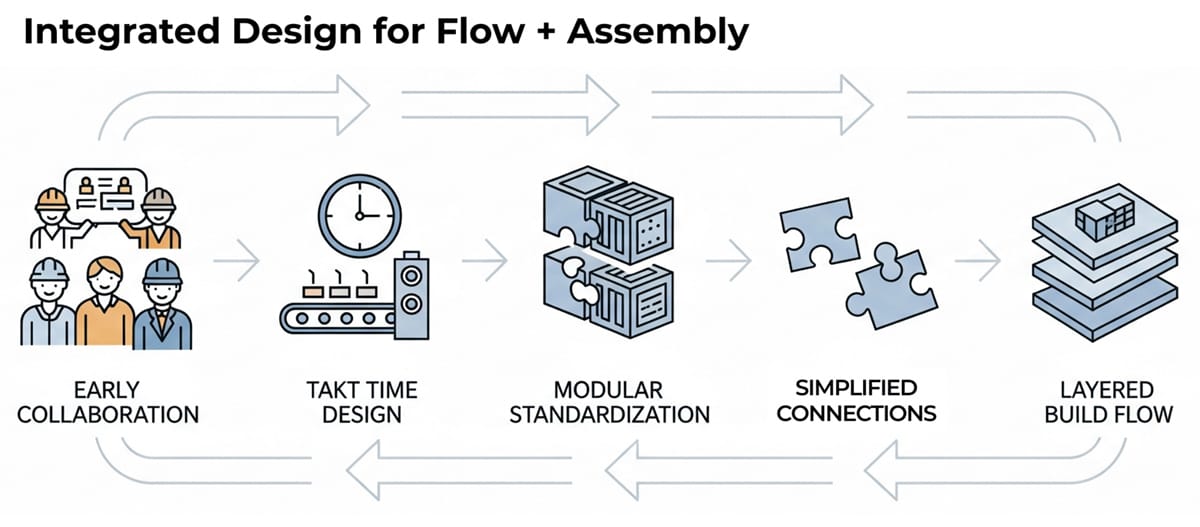

Integrated Approach: Co-Designing for Flow + Assembly

To avoid these pitfalls, DfMA must be paired with flow mapping from the outset. Here’s how modular firms can align design and production:

- Involve factory stakeholders early: Bring manufacturing, logistics, and quality leads into the schematic design phase. They’ll spot issues architects miss and flag features that increase takt time.

- Design around takt time: If your factory has a 4-hour takt, make sure the module can be completed in repeatable, leveled work packages within that window. Design tasks to fit tactically within each station’s cadence.

- Use a standardized grid:

A 4’/2’ planning grid aligned with material sizes reduces cuts, waste, and layout errors. Standardization also supports training, cross-functional flexibility, and procurement efficiency. - Simplify connections: Use plug-and-play MEP assemblies, universal headers, and snap-together framing details. Minimize fastener variety and ensure all joints are tool-accessible without repositioning.

- Build in layers: Enable each station to complete its layer of work fully before the module moves on. Avoid any task that requires a module to be brought back upstream or held out of flow.

These actions require shifting from a siloed to an integrated design process. Architects, engineers, and production teams must co-develop solutions. When they do, the factory becomes a co-creator of value rather than a downstream constraint.

Co-design loop integrating factory flow principles into every design phase — from collaboration to layered production.

The ROI of Flow-Driven DfMA

When done right, designing for flow unlocks impressive returns:

- Throughput increases of 2X to 5X, even without adding labor or equipment

- Cycle time reductions of 30-50%

- Dramatic quality improvements, due to reduced handling and rework

- Happier teams, with clearer roles and less firefighting

There are also indirect gains: improved factory morale, fewer change orders, and stronger client trust. When output becomes predictable, sales teams can promise confidently — and deliver.

Importantly, these gains scale. Flow-based DfMA creates a resilient operational backbone that allows for site variability without sacrificing internal consistency. That’s a key to achieving modular’s promise of mass customization.

DfMA Is Not Enough Without Flow

DfMA is a powerful tool — but only when wielded in service of Lean flow. The modular industry can’t afford to treat design and manufacturing as separate domains. When they’re integrated, factories hum, projects deliver on time, and customers get exactly what they were promised.

If we want modular construction to fulfill its potential, we must move beyond designing for assembly and start designing for flow. That means embedding flow principles in the earliest design conversations, empowering production teams to shape those designs, and viewing every product through the lens of factory fit and sequencing.

The future of modular isn’t just smarter design — it’s synchronized design. And that begins with DfMA that flows.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.