Hawthorn Extended Stay by Wyndham—Jackson, WY

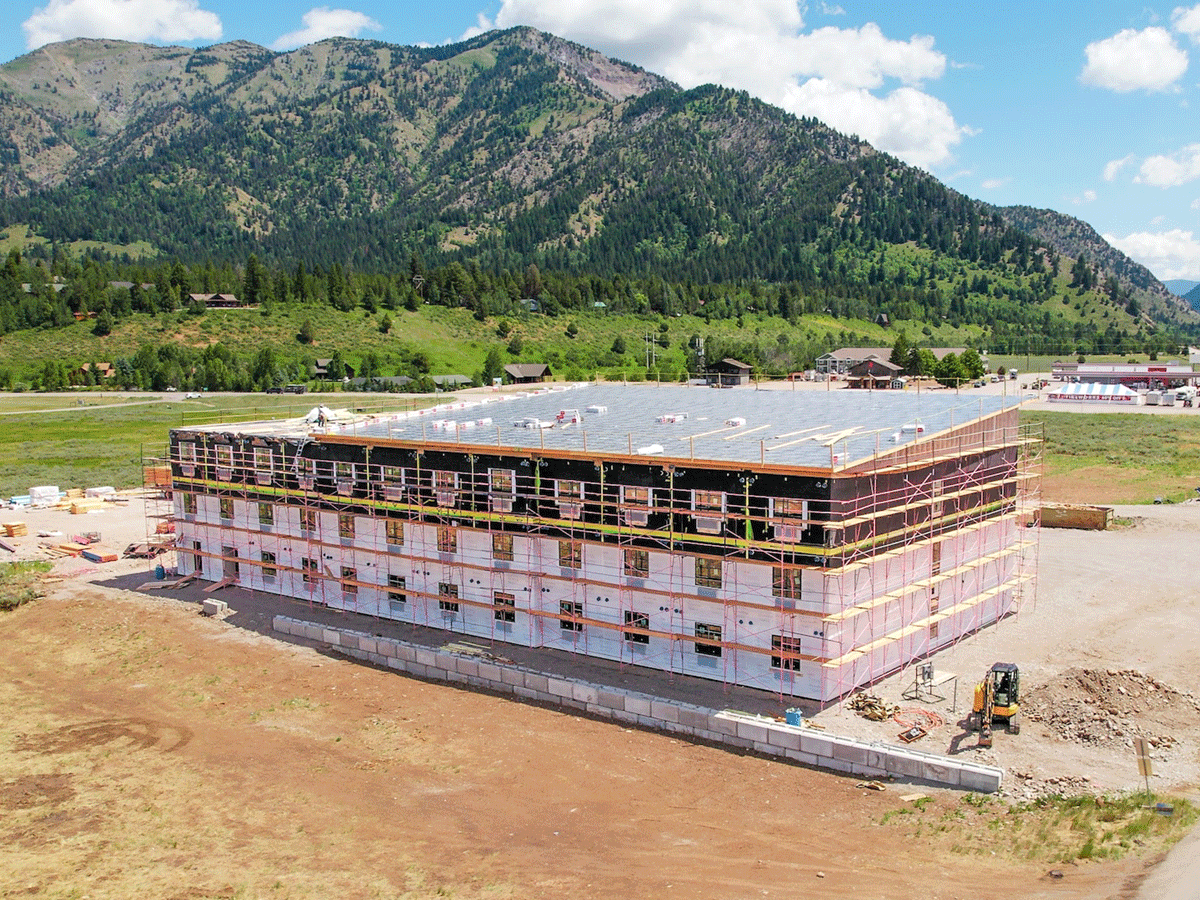

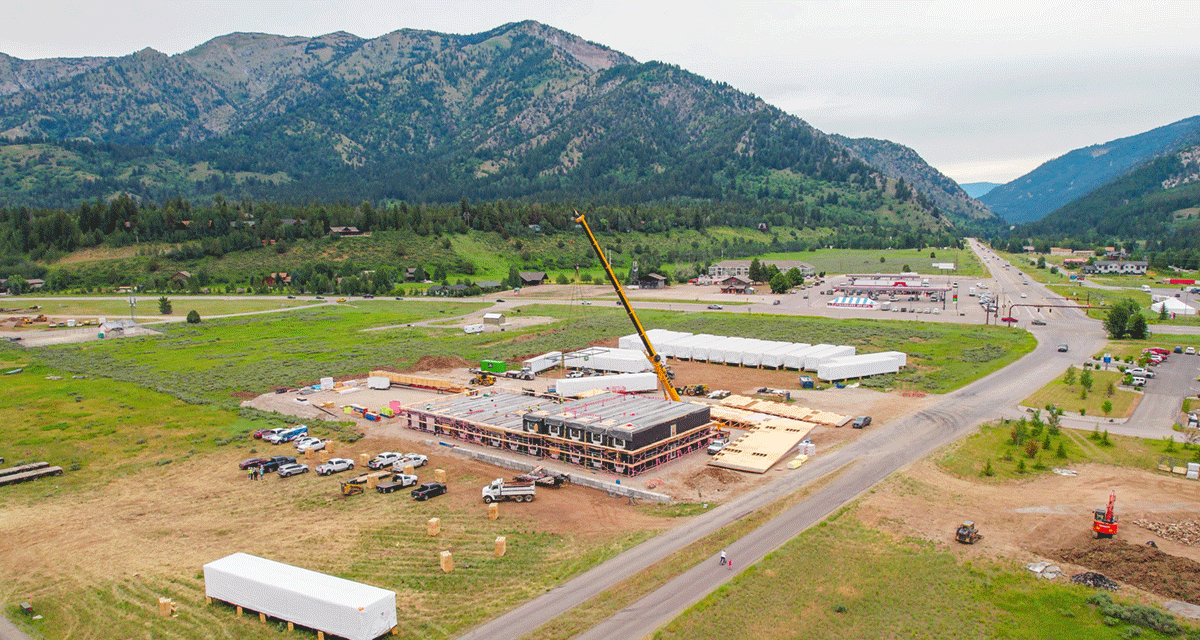

Few places are as picturesque as Jackson, Wyoming. That can be both a blessing and a curse. The scarcity of housing has forced even dual-income families to make a tough choice: commute from the few towns nearby with scarce but less costly housing, or leave their dream community. People like Casey Rammell are attacking this challenge on multiple levels—and they’ve tapped Autovol for help.

Growing up in nearby Driggs, Idaho, Casey has built a range of housing and accommodations in the area, and cofounded GCHB Venture with partner George Masing. Bringing housing to these parts takes a lot of know-how and ingenuity. Mountain resort conditions pose a triple threat: short build seasons, lack of local workforce, and a huge imbalance in housing supply and demand.

“We’re attacking a 3,000-unit problem 60 units at a time,” Casey shares. “The quicker we can turn more projects, the sooner we’ll bring some real impact. It starts with being able to house the crews we bring to the area during the summer months when lodging prices are astronomical.”

Casey had tried projects using panelized and containerized approaches that left him unsure, but still determined to try again. He and George saw automated modular as a possible silver bullet worth reconsidering. Reaching out to Autovol soon helped them get on board.

“We were still very interested in the process, but we had to find the right company to do it with,” Casey said. “Once I went over and walked Autovol’s plant to see how they did it and what their inspection process was, it closed all the gaps for us right there.”

Initial Autovol visits included Casey and George as well as Autovol’s CEO, Rick Murdock; CTO, Curtis Fletcher; Director of Business Development, Michael Merle; and Director of Preconstruction, Steve Clough. Steve helped define the project upfront by designing a preconstruction checklist that aligns developer needs with modular design and factory best practices to optimize efficiency and constructability.

Before hitting Autovol’s factory floor, the project was designed and modeled by Prefab Logic, another firm co-founded by Rick and Curtis. The design was created using Prefab Logic Housing products, developed by Curtis. Already factory-proven and site-friendly, the predesigned products accelerated the process for the developer/architect significantly and reduced the overall design costs. These products also leveraged the power of standardized design and supply-chain materials to take advantage of economies of scale.

“The initial design came together in a matter of a couple hours,” Curtis says. “That formed a good basis to customize with some customer-specific features. With these tools, we can establish a starting place and customize a design in a fraction of the time. At the same time, the design is basically vetted for constructability in the modular factory and onsite. Besides speed, these tools also greatly simplify materials procurement and project execution.”

The plan was to build the project in two phases. This would enable the property to open sooner and start accommodating guests while completing the second phase. The digital twin was designed to provide a complete factory-ready model for both phases upfront. That gave the factory everything it needed to bring each phase into production quickly. It also enabled everyone a way to plan both phases ahead of time, and begin prepping the site in advance.

“All the stakeholders leaned into this project and I think it really paid off in quality and strong execution,” Steve says. “We had developed a preconstruction checklist to define things upfront. It paid off as everything came together. Things like the room size put Autovol’s module length limit to the test, but the factory crew was ready, and they delivered.”

All the careful planning and collaboration enabled the finished modules to begin shipping immediately after factory completion. Seasoned crews from Snake River MEP and Accuset Construction were keyed up to set the building at breakneck speed.

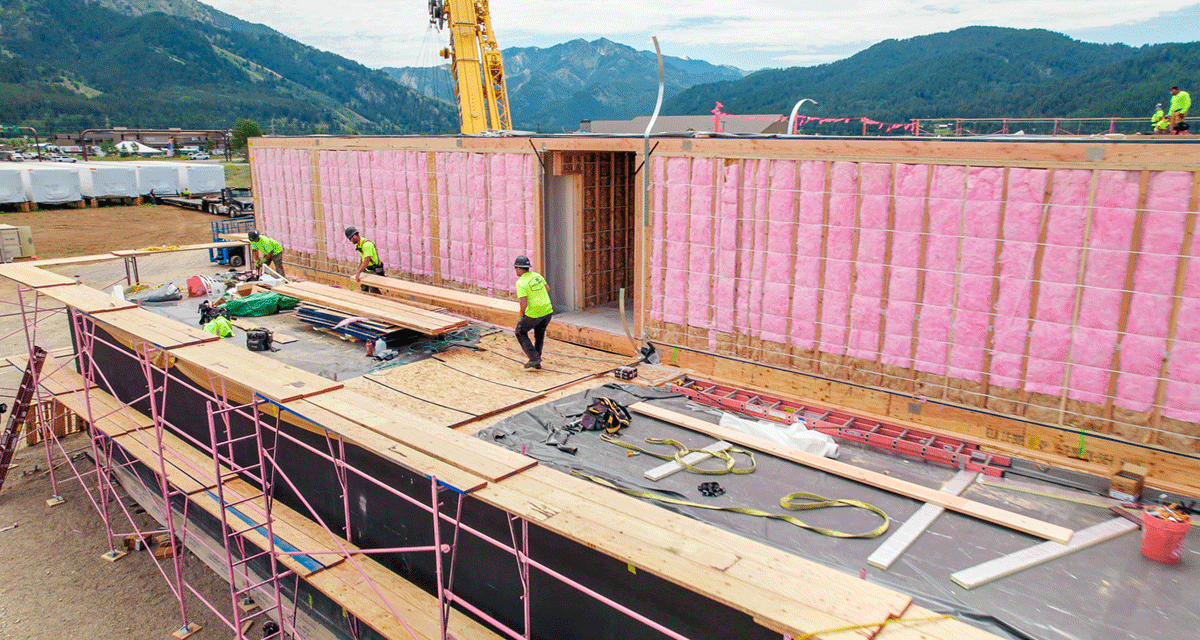

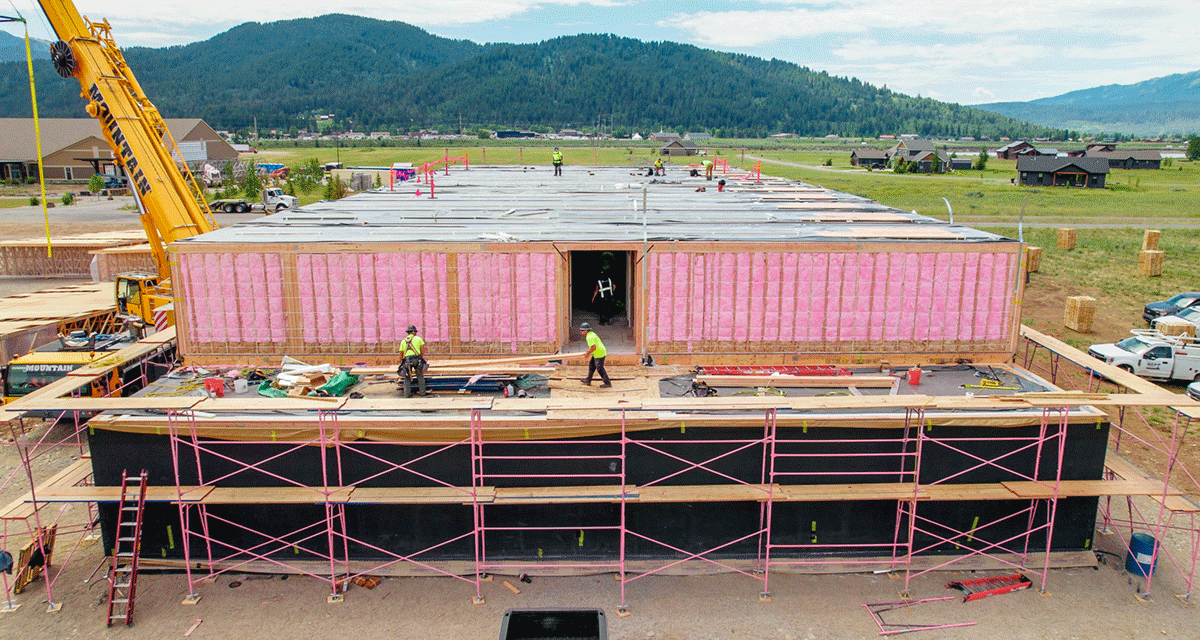

“Onsite logistics were amazing,” Steve says. “And the alignment turned out extremely tight, with tolerances of 1/8-inch.” Some advanced approaches made the onsite set process especially efficient. Autovol onsite services director Joe Sievers and Accuset founder Kirk Hall brought forward a smart suggestion: pre-building the roof in pieces on the site foundation in advance.

While the modules were enroute from Nampa to Alpine, an onsite team sheeted prebuilt roof trusses on what would become the building foundation. This sped up the completion of the roof structures, as well as the “dry in” process essential to protect the building from any potential rain.

“We finished the roof structures on the ground,” Casey says. “They swung them out of the way while setting the modules, then set them on top. We probably got the roof sheeted in a quarter of the time on the ground than we would have in the air. With this approach, it had us pretty much dried in after about 10 days.”

At this writing, the project is still a few months from occupancy. But many of first-phase rooms are already reserved for long-term guests including GCHB Venture crews, and staff at a clinic in Alpine eager to provide housing for healthcare staff in such a limited market.

“This project would have gone 18 to 24 months on a conventional schedule. We’ll do it in eight,” Casey says. “That kind of speed is good for everyone. I like to do things as efficiently as possible so that everyone on the project makes money. In that process, things go quicker, we get the doors open quicker, and our customers get a better project in the end. Hopefully we’re generating a few million a year in gross revenue, so getting your doors open 10 months sooner can mean a pretty big savings.”

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.