Modular Construction for Financial Viability: The Norwalk Project Case Study

by Konstatin Daskalov, VP of US Operations, Stack Modular

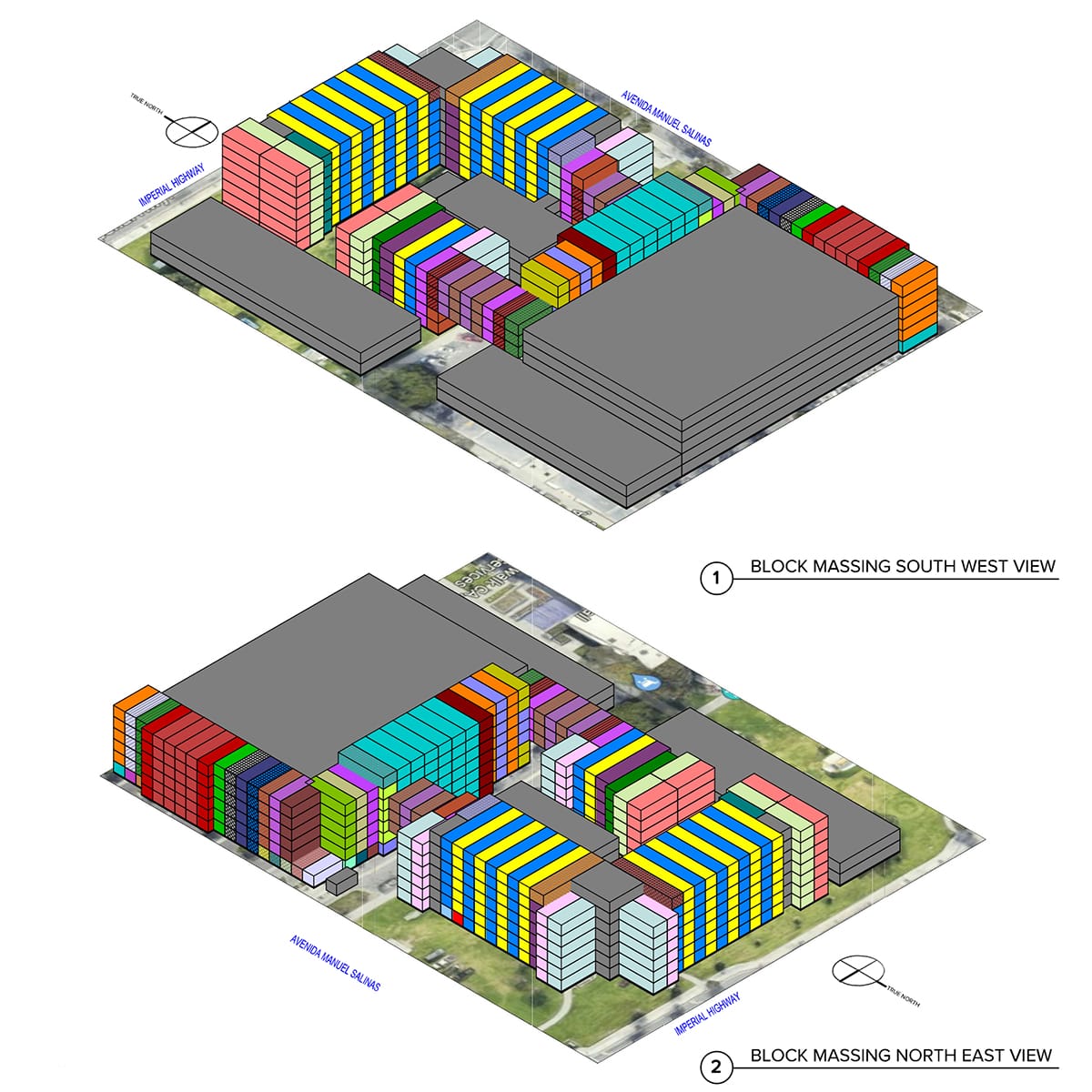

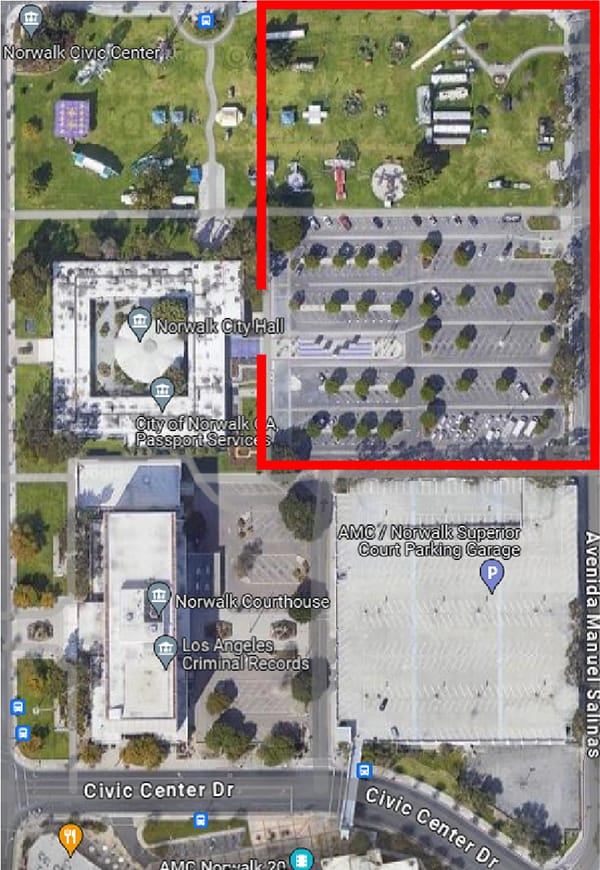

In April 2023, Primestor, a real estate owner, and developer, along with their General Contractor, approached Stack Modular to evaluate their project, named “the Walk.” This multi-family residential complex is situated in Norwalk, California, and comprises two buildings with a combined footprint of 139,150 sq. ft. The development includes 58 dedicated affordable housing units and is slated to be the largest residential modular construction project in North America to date.

The initial on-site construction pricing provided to Primestor exceeded their budget by 25%, making the project financially unfeasible. Primestor enlisted Stack to assess the original project design and explore the benefits of Stack’s modular construction approach.

Stack’s Design team conducted a comprehensive review and Modular Design Analysis (MDA) of the project. They determined that a complete redesign for modular construction was necessary and recommended engaging Assemblage-Works Inc (AWI), specifically Michael Mathews, for the modular redesign.

Stack Modular provided preliminary modular pricing, proving to be significantly more cost-effective than the initial on-site construction estimate. Additionally, they presented a detailed Scope Delineation Matrix for the original General Contractor. Despite this, the updated estimate from the original project’s General Contractor remained higher than Primestor’s target budget. Primestor then sought new competitive bids for a general contractor and selected Bernards Construction based on their modular experience and collaborative approach.

Recognizing the need for an Integrated Project Delivery (IPD) approach, Stack Modular organized a 3-day Design Charette in August 2023, fostering collaboration among AWI Architects, Primestor, and Bernards. The combined team of consultants and engineers collaborated in an open forum discussion, preserving the original design intent, and addressing factors like Unit Mix, Retail spaces, open space, and entitlement restrictions. After multiple iterations, a new concept design was finalized in June 2023.

Project Snapshot

Owner: Primestor

Type: Multi-family residential

Modules: 516

Buildings: 2

New Housing Units: 373

Floors: 7 / 5

Total Gross Area: 681,129 sq.ft.

Modular Gross Area: 356,129 sq.ft

The IPD collaborative approach resulted in an additional 20% reduction in pricing for both on-site and modular components, making the Norwalk project financially viable. Since then, all team members have been actively engaged in pre-construction efforts.

Stack Modular is set to build a full 1BR / 2 Module Unit for review by the end of May 2024. This will allow Primestor and the development team to assess the modular structure, MEP systems, and finishes, providing a valuable tool to identify any issues before Stack proceeds with full fabrication in October 2024.

The Norwalk project serves as a prime example of how Off-site Modular Construction, in collaboration with Architects, Consultants/Engineers, General Contractors (GC), and Mechanical, Electrical, Plumbing, and Fire Protection (MEP/FP) Subcontractors, can make projects financially feasible by closely working with the Owner/Developer under an Integrated Project Delivery (IPD) approach.

More from Modular Advantage

How Stack Modular Is Using AI to De-Risk Mid- to High-Rise Modular Construction

Artificial intelligence is no longer a future concept in modular construction—it is already reshaping how complex buildings are evaluated, designed, and delivered.

Gearing Up for the 2026 World of Modular

The Modular Building Institute (MBI) is bringing its global World of Modular (WOM) conference and tradeshow back to Las Vegas in April, and with it comes some of the industry’s best opportunities for networking, business development, and education.

New High-Rise Modular Apartment in Abu Dhabi Points Toward the Future of Multifamily Construction

Eagle Hills International Properties chose the BROAD Holon Building for a 16-story market rate apartment building in Zayed City, a central business district of Abu Dhabi. The project highlights the potential of the Holon system of volumetric modular construction to accelerate housing delivery.

MBI Announces First Ever Industry Apprenticeship Program in Collaboration with Marshall Advanced Manufacturing Center

MBI recently agreed to partner with Marshall Advanced Manufacturing Center (MAMC) to provide bona fide USDOL-approved apprenticeship programs for the industry.

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.