26 Stories in 5 Days - How BROAD Sustainable Building is Redefining the Speed of Modular

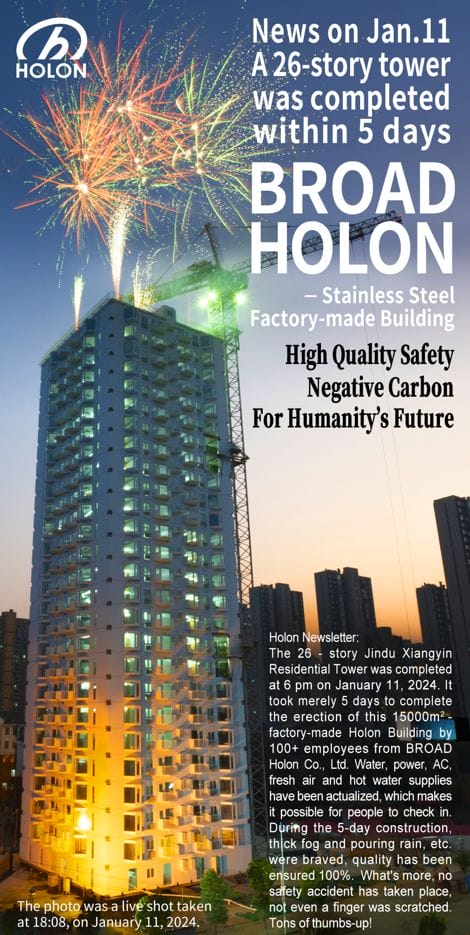

On January 7, 2024, BROAD Sustainable Building began assembling the new 26-story mixed-use Jindu Residential Tower. On January 11, just five days later, construction was completed.

But for BROAD, this was just another day at the office.

In fact, the Jindu Residential Tower represents the 16th generation of BROAD’s Holon Building concept, a modular construction design that uses foldable, container-sized units that BROAD first started developing nearly 15 years ago.

“BROAD Sustainable Building was founded in 2009,” said Jeremy Zimman, Director of Marketing, Holon Modular Building Systems at New Jersey-based BROAD USA, “in response to a large earthquake that happened in China in 2008, close to where our parent company, BROAD Group, is based. There were tens of thousands of people who lost their lives. Our chairman and founder saw that these buildings made of concrete were falling like dominoes, so he resolved to make more durable steel buildings.”

And while the use of steel wasn’t exactly revolutionary, BROAD’s embrace of stainless steel is.

“We transitioned to stainless steel about five years ago,” said Zimman, “because we realized the mechanical properties of stainless included not only non-corrosion, which is good for facades, but stainless steel also has a great ductility—the ability to withstand tensile stress. That's the reason we chose stainless for our load-bearing members. We're the first to do that.

“So now,” continued Zimman, “even though our volumetric product is just two years old, we’ve been in a continuous state of innovation. For instance, in the first Holon building that we built two years ago, the beams had to be put in on site. And now, when we lower the modules, the flooring system of those modules have the beams built in. So, there's no welding on site. It's only bolting. We have the cranes ready; we just pick and place, stack, bolt, connect utilities, and we're good to go.”

“Our building is turnkey,” said Zimman. “When construction is over, it's move-in ready. It includes all the fixtures like air conditioning, our own ventilation system—energy-recovery ventilation, which is a principle of Passive House—that’s included. Even water tanks are in place.

“The only thing not included is movable appliances. Refrigerators, washers, dryers, dishwashers, microwaves; other than those appliances, the building is ready to occupy.”

The Jindu Residential Tower was assembled in just 5 days by BROAD Sustainable Building.

After the 5-day assembly was complete, the building was move-in ready; the only things missing were the appliances.

The Importance of B-CORE

BROAD’s patented B-CORE flooring system is the key to these efficiencies. It is a sandwich structure brazed in a special oven at 2000 degrees, which enhances the inherent mechanical properties of stainless steel. One 40x8 B-CORE "slab” can be produced every two minutes.

“The Jindu Residential Tower has 264 modules, which are all either a room module or a lift module. And because the walls in the Holon Building aren’t load-bearing, we’re able to configure the room modules flexibly. That enables us to produce a very small number of physical module types, and to crank them out at high volume. And that keeps our costs relatively low. So, even though we're using stainless—which is not the lowest cost material—we gain economy of scale through very high volume production.”

Related Reading:

B-CORE: The Modern Material from BROAD

“B-CORE is composed of two stainless steel plates with an array of stainless steel tubes fused between them,” says Sunny Wang, General Manager at BROAD USA. “Copper foil is fused to the stainless steel base material during brazing. Because the metals have different melting points, they can stick together very strongly. It looks very simple, but it’s super-light and super-strong.”

Production, Construction, and Logistics

BROAD’s latest project utilized 100 individual builders working alternating shifts, plus one mobile crane and one tower crane. But despite the constant onsite activity, BROAD’s Holon builds go up quickly and smoothly thanks to the predictable, standardized nature of the building’s components and the efficiency of their production.

“For this project,” said Zimman, “the logistics were relatively simple because the building is going up not far from our factory. But wherever we build, we can utilize a standard flatbed truck. We designed the modules to the size of a standard 40-foot-long shipping container for easy global transport, maritime and on land. So, we can go across any jurisdiction in the US, for instance, on a flatbed.

“Another critical factor in our logistics is the capacity of our factories. We’ve streamlined our production to the point where we can easily produce each module in 21 minutes.”

BROAD livestreamed the building's complete onsite assembly on YouTube.

Looking Ahead

Twenty-six stories may seem like a lot for a modular building, but the plan, eventually, is to go much higher. “There is actually no limitation for the height,” says Sunny Wang, President of BROAD USA, “because we take advantage of the stainless steel. It's strong enough that we can go as high as we can design it.”

With the proverbial wind at its back, it’s only a matter of time before BROAD’s Holon buildings are seen far and wide. And besides their upcoming projects in China, the Philippines, and the UAE, plans are also in place for Holon Buildings in the Unites States.

“The Holon modular system enables the construction of tall residential buildings at great speed, and we look forward to deploying this technology to shorten the construction cycle and alleviate the severe housing shortage in the U.S. and Canada,” concluded Zimman. “Right now, we’ve got plans in place for Ohio, Texas, and California. As soon as we can say more, we absolutely will.”

About the Author: John McMullen, PCM, is the marketing director for the Modular Building Institute. You can reach him directly at mcmullen@modular.org or on LinkedIn.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.