CertainTeed's ONE PRECISION ASSEMBLIES™ Panelized Solution

Using the latest advances in building science and prefabrication, CertainTeed developed these wall, floor, ceiling, and roof panel assemblies to meet the needs of builders and developers wanting to build higher-performing homes, faster. Prefabricated using best-in-class structural systems, insulation, windows, doors, weatherproofing, and finishes all designed to work together, these fully-constructed building panels are precision-built in a controlled environment for precise quality assurance, adherence to design, and minimal waste. The higher quality combined with the latest advances in energy and moisture simulation translates to better performing, more durable homes, while significantly increasing jobsite speed and safety. Find CertainTeed in MBI’s member directory to discuss modular building projects in your area.

© CertainTeed, Photographs by Mark Bealer | Studio 66

“With our wide portfolio of building solutions and deep building science expertise, CertainTeed is uniquely positioned to bring exceptional value,

performance, and simplicity to the construction industry,” said Dennis Michaud, Director CertainTeed Platforms and Managing Director of CertainTeed Offsite Solutions. “We’ve seen a real need for a product like this, and now we’re nearly eliminating the challenges related to diverse, evolving codes and customer expectations around speed, sustainability, and safety.”

This launch marks a pivotal expansion of CertainTeed’s comprehensive suite of building solutions and is a prime example of how the company is making good on its promise to “make the world a better home.” With all panels customized to the builder’s design and typically exceeding local building codes, it is easier and more cost effective than ever to achieve industry-leading quality, productivity, and sustainability.

“We are confident that ONE PRECISION ASSEMBLIES will play a major role in construction as it offers a way to address current sustainability needs

and provides a solution to the ongoing housing and labor shortage,” adds Michaud. “With CertainTeed’s solution-minded strategy, market-leading

portfolio, deep building expertise, and phenomenal partners and customers, we have all of the ingredients to bring a significant, positive change to the construction industry.”

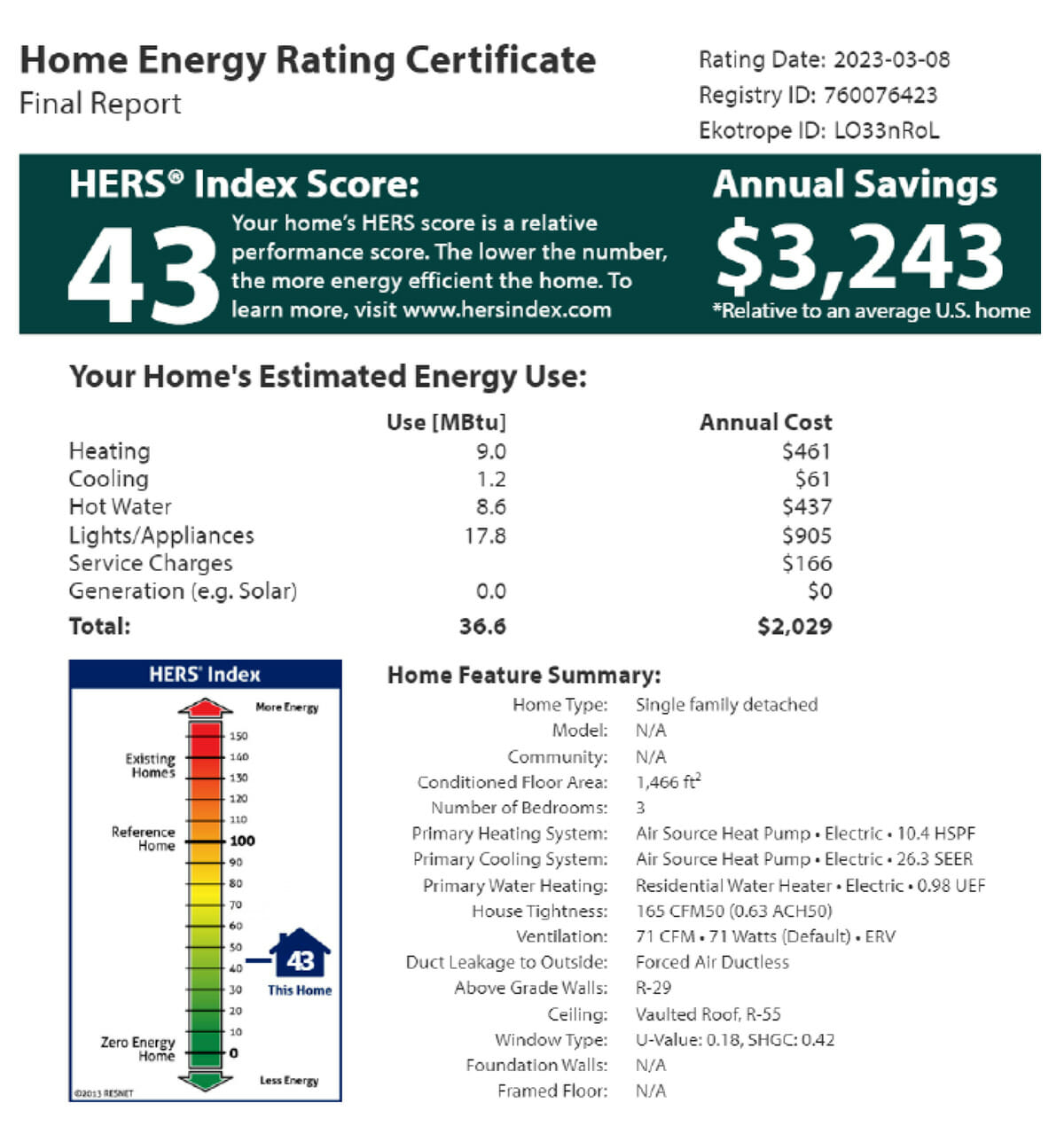

ONE PRECISION ASSEMBLIES are engineered to meet local building codes and the requirements of various energy and sustainability certifications, typically consuming less than half the energy of other new homes. While lead times vary, in-factory production is usually less than a week, with on-site installation of the wall panels in less than three days. The result is a watertight, high-performance home ready for final builder customization to the desires of their local market and customers.

“We have listened to the needs of builders and developers asking for solutions bringing simplicity and speed,” said Mark Rayfield, CEO of CertainTeed and Saint-Gobain North America. “And following our group core values, the launch of ONE PRECISION ASSEMBLIES also addresses broader needs around labor scarcity, the need to build more homes faster, and in particular the desire for buildings that require less energy and maintenance while being healthier for building occupants and the environment.”

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.