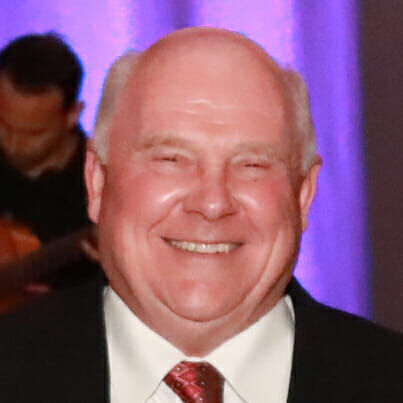

Roland Brown Looks Back at His Story of Success With Ramtech and His Career in the Commercial Modular Industry

Roland Brown was VP of Design and Development at Ramtech Building Systems, Inc. He is now happily retired.

Roland Brown never imagined his life would turn out this way.

He retired from a nearly 50-year-long career, starting off as a draftsman in the mobile home industry to becoming the VP of Design and Development at Ramtech Building Systems, Inc., a design/build construction company in Mansfield, Texas with its own modular manufacturing facility.

His career journey—all the more illustrious thanks to his dedication to hard work—led him from drafting table to the structural design of modular structures. It also led him to meeting rooms as part of the Texas Industrialized Building Code Council and MBI’s Board of Directors. He believed with an unyielding conviction that if he studied and learned, he could eventually build a career.

And he did—without a traditional bachelor’s degree.

He is the rare retiree from an industry that touts peers in similar positions with secondary and tertiary degrees. He’s worked on thousands of buildings amassing over sixteen million square feet of structures built.

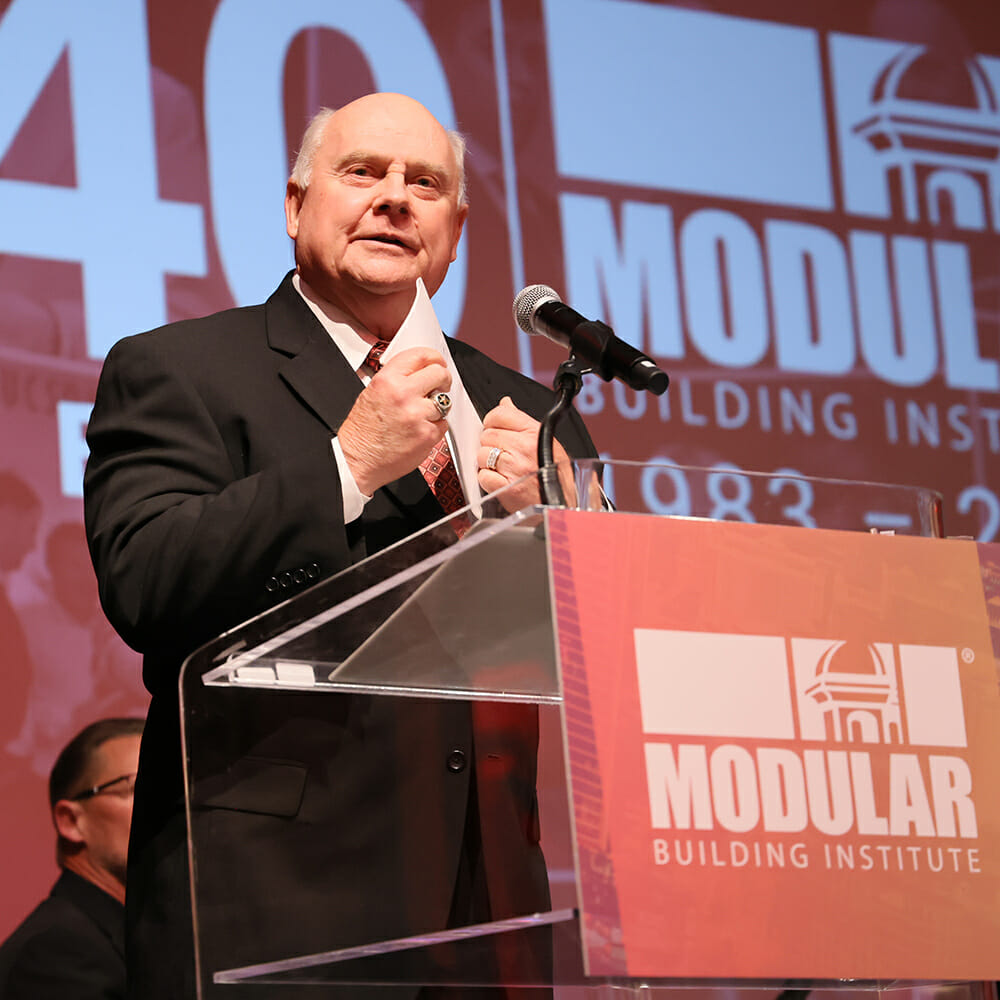

Roland’s unusual path to the modular building industry is one for the history books—and an example for anyone looking to learn outside of the box. He was recently inducted into the Modular Building Institute’s Hall of Fame for his work both in the private and public sectors, as an innovative designer and steward of modernizing and implementing building codes in support of the modular industry.

Roland Brown addresses the crowd at the 2023 World of Modular following his induction into MBI’s modular construction industry Hall of Fame.

Big Dreams Starting Off in a Small Town

Born in a small mill town of less than 500 people in North Carolina, Roland’s early career naturally pushed him down the road of building design, reading building codes, and structural analysis.

“I realized that using mathematical methods to model and prove building design performance was logical and a perfect fit for my personality” he says. “As my knowledge and experience grew, I found it easy to visualize structural paths and forces at a high level, something that not all engineers enjoy.”

He briefly attended Appalachian State University, where after two years he had exhausted his savings, realizing that his dream of a football scholarship was not going to happen. So he shifted his focus to finding a job and earn a living.

And so, Roland studied at what he calls the “University of Dining Room Table.”

Moving Beyond the Drafting Table

His first career job was as a draftsman at a mobile home factory located in Siler City, North Carolina and eventually to their corporate offices in Lenexa, Kansas.

In addition to his drafting duties at the corporate office, he was asked to assist in the company’s structural testing lab. He learned a lot from the experience. And it launched his interest in learning how structures performed.

After a few job shuffles, he landed a job at PFS Corporation’s Dallas office—where he decided it was time to do a deep dive and learn more about structural design calculations. But he wasn’t sure that it was possible to learn completely on his own. Nevertheless, he decided to start self-studying, and credits two engineers at PFS for their encouragement. Though at first it wasn’t without struggle.

“I went to the University of Texas Arlington bookstore and bought all the textbooks that I thought I needed to self-study,” said Brown. “Each night I would open up a book and tried my hardest to wade my way through them. And after about three to four weeks, I got a little frustrated. So, I thought, 'well, I’ll fess up to the engineers in the office.'”

He sheepishly thought his self-studying idea was laughable and feared what he might hear from his professional friends—but the engineers were nothing but supportive. With caveats.

“They said, ‘yes, we feel you are smart enough to do it,’” said Brown. They asked him to bring in the books, to see what he purchased. “Later, after looking at my stack, they said, ‘these books won’t help you. They teach you some theory, but they won’t teach you to be an engineer.’”

These two engineers put together a reading list for Roland, telling him that it would take considerable amount of time and discipline. They said, even if you study 30 to 40 hours a week for six months, none of this will make sense.

“One year, you can do many calculations, but it still won’t make sense…somewhere around two, two-and-a-half years, the light will come on,” he said. “But you have to go through all those steps to achieve that. So that’s what I did. And it took me about two-and-a-half years. One day, I was driving down the road, and in one flash I realized that my level of understanding was there. The goal was achieved.”

His dedication and knowledge gained led him to a job offer with PBS Building Systems in 1982. At the time, PBS was considered a leader in the commercial modular industry and wanted Roland to help develop the structural concepts needed to pull off those more complex designs the market was beginning to demand. “I knew only a fraction of what I know now,” he said. “It was an extremely stressful period, which made me spend many hours researching things. But bottom line, I got much smarter and more confident during that time.”

Roland Brown accepts MBI’s award for Outstanding Achievement at the 2018 World of Modular.

Mike and Matt Slataper, Linc Moss, Roland Brown, and others representing Ramtech Building Systems at the 2018 World of Modular.

Building Atop a Foundation of Knowledge

Roland left PBS and moved back to Texas to manage a commercial modular plant, but due to poor economic conditions, he was asked to close the plant. To pay the bills he returned to PFS’s Dallas office to work on a contract basis, while looking for full time employment.

During that time, he received a design package submitted by Ramtech Building Systems for review. While poring it over, Roland noted some structural discrepancies and returned the submission with his deviation letter.

Cue one call from Mike Slataper, the owner of the newly formed modular building company.

“He called and he was very upset,” he said. “We had this very adversarial initial meeting, but then he realized I came from PBS. And he knew the CEO John Hardy, as they were both on the MMOA board at the time, and he wanted Ramtech to be able to do the type of things that PBS was known for.”

Mike wanted to hire Roland based on this first meeting but needed some additional details from Hardy. Mike called to query about Roland’s job history and received a glowing recommendation about Roland’s abilities.

He was hired as Ramtech’s engineering manager and moved further up the ladder, eventually becoming VP of Design and Development in 1998. Roland stayed with Ramtech for over 34 years.

“The Guy in the Back Corner Office” Becomes Presiding Officer

Roland could have remained doing his job responsibilities at Ramtech, creating innovative design work that led to the firm’s success and recognition for design and construction of technically demanding modular projects. But he was also that rare gem in the industry—the one with a natural eye for analyzing building codes and regulatory requirements.

“I was the guy that could show up with the background [and] with the knowledge,” he says. “And it was because I was the guy in the back corner office who typically was punching the calculator and reading the books, doing the labor.”

To build competency in understanding various regulatory systems is immense, he said. It requires that you also understand the intent of the building codes.

“Let me tell you, there’s a lot more exciting things to do than reading building code books and researching state regulations. But my willingness to work in those areas along with my engineering background, not only allowed me to fulfill my duties at Ramtech, but also become a resource for industry through the MBI.”

The Texas Industrialized Building Code Council came calling in 2010, and Governor Rick Perry appointed Roland as one of three members on the 12-person board to represent the modular industry. He was also appointed by Governor Greg Abbott for additional terms and stayed on the board for 12 years, becoming the presiding officer in 2018. In fact, Roland is the first Council member from industry to receive that honor.

“When three building officials from cities in Texas request an industry Council representative to be the presiding officer, that makes a positive statement for what we are trying to do with our industry through the MBI,” he said. “And for me personally, it was a wonderful compliment.”

His self-effacing nature yielded not only a deep knowledge base for not only the State of Texas, but MBI as well. While juggling a full-time job and his council position, he also joined MBI’s Board of Directors. After his initial board term, he was moved to the MBI executive committee, becoming board president in 2019. Roland was also awarded the prestigious MBI Outstanding Achievement Award in 2018.

He considers his work on governmental issues to be the hallmark of his committee experiences, as his work with the State of Texas bolstered his appointment on the MBI board. And with MBI’s Board of Directors, he was part of the team that helped complete new standards with the International Code Council.

Looking Back At A Career Well Built

Roland retired from his position in July 2022. But in those years leading up to retirement, he’s seen a lot of technical changes in the modular industry, and a lot of complexity requiring an ever-growing amount of expertise.

“I think there’s more potential in the industry now than there’s ever been,” he says. “Building codes are much more inclusive and complex. Business plans must take into account factors that differ from one region to the next. What works in one geographic area might fail in another.”

For Roland however, his career success boiled down to one thing, and it’s something he wants new folks in modular building to keep in mind.

“If you want to be successful, you must be a self-starter,” he says. “I knew I had to be smart because I didn’t have the college degree from a big name university to stand behind. So every time I went in, I knew it was my knowledge on the line and nothing else. I had to be well prepared. You know, you don’t show up every day with the same knowledge you had 20 years prior. You must be learning every day, and if you’re not willing to do that, you can’t do what I did.”

He’s turned in his quadrille pad and calculator, and now Roland looks forward to downtime with his wife and grandchild. He’s also in the process of moving his sailboat from a lake near Dallas to the Gulf Coast for some extensive coastal cruising—fulfilling another goal of his since his early 20s.

About the Author: Karen P. Rivera is a freelance writer and editor with a passion for storytelling. She is former United Nations-based reporter, with experience covering international breaking news, venture capital, emerging healthcare tech, and the video game industry.

More from Modular Advantage

Samantha Taylor: Leading the (Modular) Design of Tomorrow

“With modern technology and the way we’ve all embraced things like BIM, file sharing, and video conferencing since COVID, it’s easy to collaborate with companies in Austria, or Singapore, or anywhere else in the world.”

Greg DeLeon: Military Engineering to Modular Design

Greg DeLeon, a structural engineer at ISE Structural Engineers in Temecula, California, can tell you not only how large a beam needs to be to support a house, but also how much explosives you’ll need to take it down, thanks to his unique combination of professional and military experience.

To Remake North Minneapolis, Devean George Swaps Basketball for Buildings

He’s lived in Los Angeles, Dallas, and San Francisco (to name a few). He’s delivered championships with the Los Angeles Lakers and made career-defining moves with the Dallas Mavericks and the Golden State Warriors. No matter the wins, the championships, or even the seemingly impossible 3-pointers, Devean George has always returned to where it all started for him: Minneapolis.

Chelsi Tryon: Making the World a Better Place

For Chelsi Tryon, Director of Environmental, Social, and Governance (ESG) for WillScot Mobile Mini, nothing is more enjoyable than increasing the

company’s sustainability efforts while simultaneously doing her bit to save the environment.

Joshua Hart: Pushing Boundaries

Joshua Hart, P.E., vice president at Modular

Solutions, can sum up his job responsibilities in one sentence: “I do whatever needs to be done.” Hart thrives on the variety and the opportunity to be involved in every aspect of the company. And it shows! You might say Hart has come full circle.

Jamie Metzger: From Construction to Apparel and Back Again

Growing up in a blue-collar city like Edmonton, Alberta, Canada, it’s no surprise that Jamie Metzger spent some time working labor jobs on construction sites. It’s one of the most common summer jobs in the city. But that’s probably the last predictable thing about this particular story.

Victor Masso: Expanding Modular in Puerto Rico

Victor Masso joined 2 Go Storage, a company started by his grandfather and father, in 2018 to develop a modular building division in the wake of the devastation caused by Hurricane Maria in 2017. Prior to joining the company, he had worked in the industry for about four years focusing on pharmaceutical, commercial, and government projects.

Eliyah Ryals: Finding the Perfect Fit

It’s not common for people to find their perfect career fit straight out of college. It’s even less common to find it in the town you grew up in. But that’s exactly what happened when Eliyah Ryals was told about vacancies at Panel Built and made the decision to apply.

Through It All, It’s Still About the Workers

By February 2024, the number of available, unfilled construction job openings had reached an all-time high. At some point, interest rates will fall, creating another surge in demand for such workers. In short, solving the nation’s skilled worker shortage issue has never been more important.

Navigating Insurance Challenges in the Modular Construction Industry

Utilizing practical written minimum insurance and indemnity requirements, along with monitoring certificates of insurance by someone who has COI training will not yield a perfect risk transfer strategy, but the exposure will be managed much better than it likely is currently.