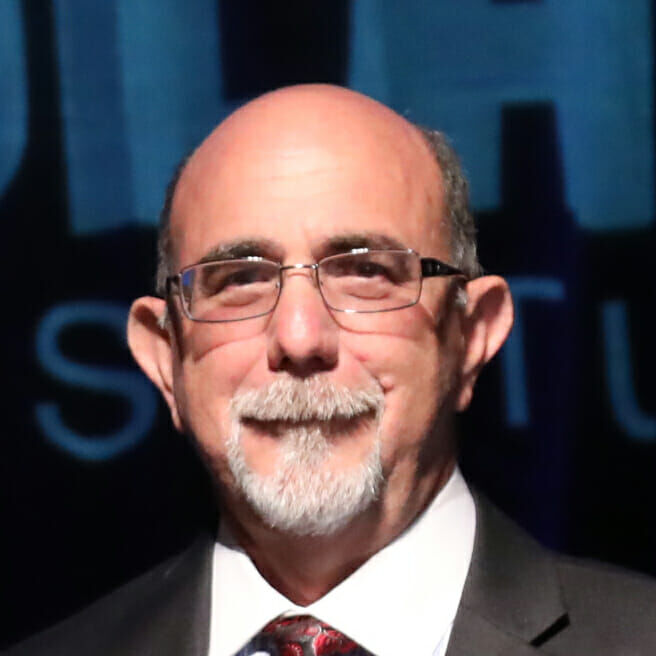

Mike Bollero, Sr: A Leader in Modular Construction

Mike Bollero, Sr., is the COO for Reliant Asset Management at Class Leasing.

“Location” is crucial for real estate, as we’ve all heard. It’s also a big factor in careers, as Mike Bollero shows. Thanks to its status as the recreational vehicle and modular building hub of the United States in the 1960s, Elkhart, Indiana, attracted plenty of local talent like Bollero.

Coming out of school in 1972, Bollero started a consulting business servicing the local modular office builders in Elkhart, such as Cliff Industries and Markline. Cliff Industries was launched by his uncle, Otto Miller, in fact. Bollero also benefited from good timing, as the modular construction industry was growing and starting to transition from the standard (for the time) 10x40 portable classrooms into construction camps and other uses for modular buildings.

A Nudge Into the MMOA

While running his business in 1983, Bollero established a business relationship with Bob McGrath of McGrath RentCorp. Incidentally, McGrath mentioned a new organization called the Mobile Modular Office Association and nudged Bollero into joining, which he did.

Tom Hardiman, Rick Bartolotti, Mike Bollero, Sr., and Steven Williams pose at the 2022 World of Modular in San Antonio.

Joining the MMOA led to serving the organization during the struggles with the International Code Council (ICC). At that time, the ICC was starting to exercise more control over more facets of the building industry. In particular, the ICC was threatening to refuse to accept already-built modular units as code compliant. Grandfathering” is the commonly used term for that process, and an unfavorable decision would have meant that hundreds of thousands of existing modular units would be essentially worthless. “We were looking at probably 400,000 leased units, and a couple billion dollars worth of assets,” Bollero said.

The ICC battle led Bollero into joining the MBI board of directors, and then later into the role of President. As President of MBI, Bollero identified several key business factors that drew his attention. “I really wanted to get our finances stronger than what they were,” he noted. “Second, we wanted to decrease the membership or the amount of board members but increase the stature of the board members. We wanted to get the owners and operators back into the board, making decisions for the industry.”

Also at that time, MBI established the Awards of Distinction to recognize great work in the industry. The Awards of Distinction were a milestone for any recipient, Bollero noted, and though he’s no stranger to taking home some accolades, there was also a bigger theme at work. “In all honesty, our first Awards of Distinction were more awards and recognition for company service, as much as for the actual building that you put in,” he said. Bollero also received the Lifetime Achievement Award for service to the industry.

That notion speaks to the overall growth of the industry from the mom-and-pop model to the vertically integrated model. “It was just nice to see that the business had evolved to where as an industry, we were no longer this cottage industry of a bunch of small, self-made businesses but we were actually turning into an industry that was recognized and doing some really neat stuff,” he said.

Mike Bollero, Sr., accepts MBI’s Outstanding Achievement award at the 2017 World of Modular.

The Industry Grows Up

From his time as a greenhorn in the early 1970s, Bollero has seen the modular construction industry mature through several phases. “When I entered it, people were basically doing construction trailers. What you put on the jobsite, and they were small,” he said. From there, though, the industry began to expand into much higher-quality products as well as into producing permanent structures. The businesses themselves also matured from the local “mom and pop” type of business into large, publicly traded companies, as well.

“In the 1990s we started building real buildings, multi-story permanent buildings. And then people started to become vertically integrated, like we are now with Class Leasing, where you manufacture your product and you sell your product. You’re not one or the other,” he noted.

In addition, the big players have come to dominate the industry, in contrast to past decades when smaller companies found their niches. “Now today, because businesses have grown to where the days of the Ma and Pa dealer are gone, basically it’s now big business,” Bollero said. “And if you don’t have $100–$200 million to get into the leasing business,

The Trend for Modular Construction

Bollero does not forecast radical changes in the modular construction industry in the next three to five years. Continued business maturation will happen, though.

“You’re going to continue to see vertical integration increase because of supply chain issues,” he said. Vertical integration requires a more robust business model overall, meaning manufacturers will be selling and leasing their output. They will also be more sophisticated in designing their products.

“I think that you’re going to see the manufacturers become much more project engineering oriented,” he said. “I think you’re going to see the bandwidth and the skill set of the industry overall increase as we push into a larger percentage of the total construction dollar mark.”

Enjoying the Ride

Since those early days more than 50 years ago, Bollero has seen the modular construction industry grow and mature remarkably. The industry has provided both enduring relationships with colleagues as well as interesting challenges along the way.

“I’ve enjoyed the whole ride. I mean, I have been blessed to make great friends, and have gone through some really good and really bad experiences,” he said. “But through it all there has always been a sense of camaraderie.”

Working on interesting projects has been another enjoyable experience for Bollero. “I’ve always felt like we’ve tried to be on the cutting edge of trying to take the projects that maybe other people weren’t going to take and doing something new and different. It never got boring. And there was always a new challenge. And that was what made it fun.”

As for coaching his younger self if he were starting now, Bollero said, “Probably to be a little bit less of a risk taker from a professional standpoint, but other than that, I don’t know that I would change much.”

About the Author: Steve Hansen is a Colorado-based writer with a focus on the built environment—architecture, construction, renewable energy, and transportation. He can be reached on LinkedIn.

More from Modular Advantage

DORÇE Navigates Mountainous Terrain, Extreme Weather to Help Rebuild Türkiye

The February 6 earthquakes in 2023 were enormous. In response, DORÇE moved quickly, obtaining a government bid to help create housing and multipurpose structures—both temporary and permanent—for earthquake victims and laborers hired for reconstruction efforts.

Modern Desert Oasis: Building Reset Hotel the Modular Way

While the off-site construction part of the Reset Hotel project has been carefully controlled and with every necessity close at hand at BECC Modular’s factory in Ontario, Canada, the remote location of the project site has created additional challenges for the on site portion of the build.

Revisiting Yellowstone Canyon Village—a Groundbreaking Modular Construction Feat—Ten Years On

With such a short building period due to impending cold, it made the most sense for park developer Xanterra to pursue modular. Yellowstone’s high visitor traffic also required some odd transportation scheduling, as traffic from the West Yellowstone entrance determined the times when trucks could unload modules. Guerdon was up to the challenge.

Built for Brutal Cold, This Modular Office Building Shines

Houlton, the county seat of Aroostook County, Maine, is a small town with a population of about 6,000 residents. Situated along the border between the U.S. and Canada, what the town is most known for is bitterly cold winters. When the U.S. Border Patrol needed new office space, a modular building approach from Modular Genius offered the perfect solution.

Panel Replacement Adds Years of Life to Navy Vessel

Panel Built, Inc., recently replaced all the wall and roof panels on a two-story US Navy barge deck house that the company had originally installed 30 years ago, giving the vessel new life. Now, the commanding officer of the unit that uses the barge said the difference between the condition and appearance from when the barge left their facility to when the project was complete was beyond his expectations of what was possible.

True Modular Building Seeks to Revolutionize Housing. It’s Next Stop: MBI’s World of Modular Europe

True Modular Building (TMB) specializes in crafting attainable, eco-friendly, and comfortable build-to-rent (BTR) housing with modern designs and customizable features, ensuring that residents feel at home both today and tomorrow.

From Toronto to Suriname: A Global Modular Building Story

When I AM Gold – a Canadian gold mining operation based in Toronto, Ontario – wanted to expand its mining operations in Suriname, it knew it would also need to expand its infrastructure. More specifically, they needed to build a mechanical services compound that would allow their local crews to maintain and equipment critical to their mining operations. They also knew that it would be a challenge.

There Were a “Sea of Challenges” for this Modular, Island Development

Question: Can modular construction be used to build a series of affordable, unique housing buildings, all styled to look like they were built in 1845, on an

island that caters to the wealthy? The answer is, of course, yes, but how the

team at Signature Building Systems and KOH Architecture got there is quite a story.

America’s Construction Economy: A Race Against Time

If the economy has been able to handle higher interest rates thus far, undoubtedly it will be able to manage the lower interest rates to come. But many economists are pointing out that the Federal Reserve may already be too late to the game. While they gradually reduce interest rates, the U.S. economy could quickly decelerate, at least based on theoretical grounds if not on the most recent data releases, culminating in that long-predicted recession. Only time will tell.

Top Five Benefits of Modular Office Space

Modular office spaces are transforming how businesses think about their work environments. These innovative structures offer a mix of flexibility, efficiency, and sustainability, making them a smart choice for companies looking to gain an advantage.