Integrated Teams and Product Thinking

for modular multi-family housing projects to reduce unit cost and increase market share.

Stuart Emmons, FAIA, is the founder of Emmons Design.

Two inches. This small dimensional increase was needed late in the design process to comply with an obscure accessibility code clearance between a toilet and a lavatory during a recent 100+ unit modular housing project I worked on. We had two options to accommodate the 2 inch increase: option 1: make the modular units 2 inches wider or option 2: rotate the toilet and lavatory 90 degrees to the party wall. Because the site design was set months before, option 1 would have reduced unit count and would have negatively impacted the economics (proforma) of the project. Option 1 was out. Option 2 would not be a big deal if it were site-built, but was significant and costly in a modular project. The 90 degree shift created a ripple effect throughout the project: increasing piping complexity and negatively impacting our wet wall strategy and wall assembly sequencing, all resulting in increased production time. The end result: increased unit cost.

It didn’t have to be that way.

The United States is facing an unparalleled housing crisis. The current housing delivery system is not keeping up. This presents a unique opportunity for innovation in housing, with modular multi-family housing being the primary interest for many housing providers and government officials. The modular industry has made great strides in the last decade, with impressive new plants and automation, but there is a potential to expand the industry, increase housing market share, and be a key partner in housing people, including helping to get people out of the tents on US city sidewalks. Integrated Teams and Product Thinking in modular projects and companies will help reduce dwelling unit cost. Reduced unit cost (compared to site-built multi-family housing projects) will help increase market share for modular housing.

h a destination and a statement piece—combining art, food, and social gathering within a compact, efficiently designed space. What makes Art²Park unique is not just its program, but its construction: it fuses repurposed modular shipping containers with traditional structural steel and concrete systems, creating a visually striking and structurally robust urban park building.

Integrated Teams

Integrated Teams are collaborative teams made up of people representing all phases of a modular project, from the client; to the developer; architect; general contractor; modular company leadership, design, engineering, estimating, procurement and production team members; project engineers; the module transporter; the site set company; and other key people associated with the project. Integrated Teams are well choreographed and highly collaborative. Product Thinking in the modular space employs fresh thinking to develop solutions (products) that are designed to accommodate a need, which are repeatable and attractive to a wide market. In the case of modular multi-family housing, that translates to a series of standardized dwelling unit modules. Product Thinking is healthy for the modular industry, but needs to be coupled with modular means and methods, building science and housing requirements to be a successful addition to modular multi-family projects.

Let’s apply Integrated Teams and Product Thinking to the 2 inch story above. An Integrated Team formed at the outset of the project, coupled with Product Thinking, would have almost certainly avoided the 2 inch problem (and a lot of other problems that slow production). If a series of standard dwelling units had initially been designed with an Integrated Team, that considered accessibility, energy, systems efficiency, code compliance, optimal layout for the market and other modular and site work considerations - production time could have been significantly reduced. In addition, full scale prototyping would have had even more cost benefit. Yes, that 2 inches might have impacted unit count and project proforma, but it would have been known at the early stages of the project. Employing Integrated Teams and Product Thinking would have helped reduce unit cost and helped grow modular housing.

The Kitchen

On one recent large scale modular project for homeless I was on the team for, the project team discussed kitchen design, gobbling up hours of meeting time that could have been eliminated by Product Thinking – having an already vetted, pre-designed, beautifully designed kitchen available for the project. Imagine one short meeting that would have just focused on cabinet colors and equipment. Instead, one of the senior development team members in the meeting wanted more upper cabinets, and with no push back, it was just agreed to. And that quick decision snowballed. More upper cabinets forced more lower cabinets (due to accessibility code requiring 50% of shelves to be in reach range), contributing to a doubling of the cost of the kitchen, and increasing unit cost. And now, the single homeless resident, with minimal cookware and tableware, will have an unnecessarily oversized kitchen. An Integrated Team and Product Thinking at the outset of the project could have assessed the kitchen from code, cost, functionality for the intended user, accessibility, rapid installation, and efficiency factors, and easily reduced the cost of the final kitchen design.

Integrated Teams. The cast of team members can be large, but if there is great communication and mutual trust, the benefits are large. Site-built projects bring together a large group of individuals who come from completely different backgrounds. In a modular project, usually even more team members are added, and making a team gel requires dedicated effort. Job descriptions need to be constantly reassessed for the needs of the company and realities of available people, and take advantage of many people’s wide levels of expertise. The Integrated Teams approach in modular multi-family housing projects focuses on early input from all team members (utilizing their experiences and lessons learned on past projects), ideally followed by prototyping, team assessment and design refinement. If an Integrated Teams approach is used well, conflicts and challenges are caught early on, and streamline the modular production process and assembly on-site. To increase modular’s success, the whole Integrated Team should continually focus on lowering unit cost through design and production efficiencies, while still maintaining a high level of quality and design. Integrated Teams will reduce unit cost.

The Lunchroom

Two modular companies I’ve visited stand out for me, where the CEO can be seen having lunch with, say, a plumber on the floor, and they talk about what can make a project better. A flat culture, not too hierarchical. Everyone’s talking to everyone to help make better solutions. Minimal divisions between office and floor. An Integrated Team. Sometimes our best Product Thinking involves listening to the front-line worker. This is well known in Japan in companies like Toyota. The Kaizen philosophy adopts a continuous improvement mindset in business culture, and front-line workers are very much part of the culture.

Product Thinking. Think repetition, think universal, think plant efficiencies. And, think jigs and setting up for automation. There is a lot of room for growth in product work (the designing and making of standardized dwelling units) in the modular space, much like the auto industry. Product Thinking is pursuing designs that work in almost all applications. Imagine a dwelling unit that complies with structural, energy, accessibility, fire and other codes in any state. Imagine, for instance, a standard kitchen used in every modular dwelling unit that complies with ANSI Accessible, Type A, Type B, Type C; IBC Chapters 11, 12, and other chapters; ADA; Fair Housing. And can be installed in a half hour. And is beautifully designed. Maybe we’ll only get to 95%, but that’s still far better than custom kitchens for modular efficiency. Product Thinking is pursuing optimal wall design, wall construction, and assembly sequencing. Product Thinking is minimizing pipe, duct and conduit runs for systems and streamlining connections. Product Thinking is simplifying or eliminating soffits. Give the client options for colors, material, equipment, exterior skin like the auto industry. Many clients will surely be receptive to a few standardized units that incorporate user needs, codes and market considerations. Standardized, universally designed dwelling units, even though they may result in some more floor area and material than site-built, will ultimately reduce unit cost.

Standardized Units for multi-family housing should be few in number, and have full production documents, cutting lists, specifications, and consider optimal production efficiency and material use. There should be a client selection platform similar to the auto industry in graphics, accessibility and number of choices. And the units should look great aesthetically, with modelling and model units that excite housing providers. There is no reason why modular interior space can’t be better designed than site-built, because Product Thinking with repetition can allow the time to refine and detail designs at a higher level than site-built designs. A few companies in the US have made great strides in this direction, and that should be expanded.

Reducing Unit Cost is the key to increasing the multi-family housing market share for modular. Unit cost is the entire completed project cost (modular and site) divided by dwelling units. This is how developers and clients will compare modular to site built. For modular projects, that includes soft costs for the entire project, modular construction, transportation, and set, and all costs for site construction. It is in the interest of modular projects to reduce site costs wherever possible and build in the modular plant – especially circulation, exterior skin, and roof as much as possible. Accessory structures and uses can bog down modular production lines, and they might make more sense to be site built. The faster a dwelling unit can be built and installed, the lower the unit cost.

Instituting Integrated Team and Product Thinking. From my earlier career days running and working in contract cabinet companies, I know the challenges in building a product company from the ground up, or transition from a contract shop to a product shop. Product takes investment, more design professionals, a different marketing strategy. However, product can be phased in over time. The modular industry can also build networks across the country to share product R&D and design, to help the industry gain housing market share and get more people housed.

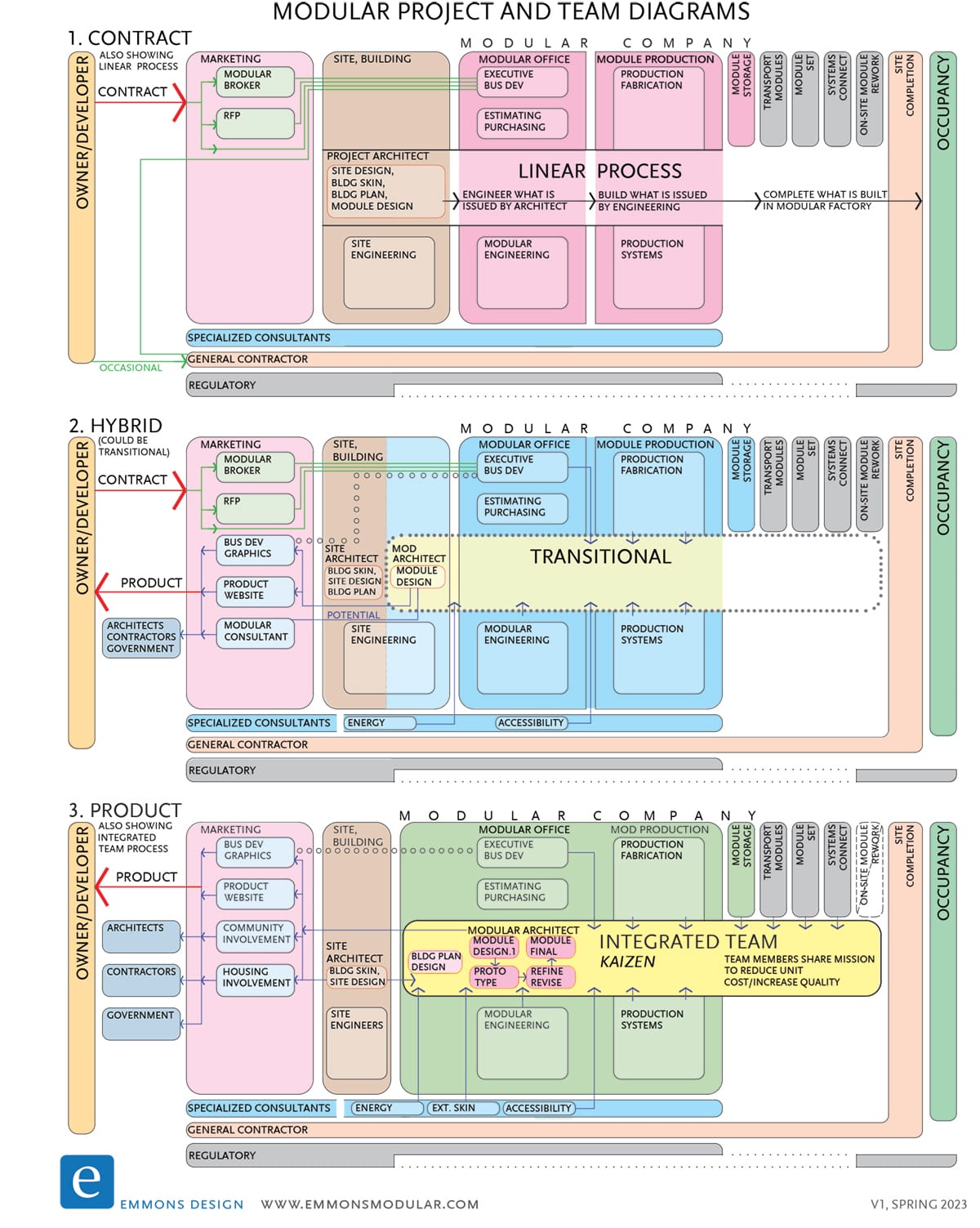

The Diagrams

In the graphic above are three diagrams entitled ‘Modular Project and Team Diagrams: 1. Contract (building projects from submitted plans), 2. Hybrid (both contract and product) and 3. Product (making and marketing a line of standardized housing units). Included in ‘1. Contract’ is a linear design and production process (ie: engineer or build what you’re given, without questioning much, or being involved in earlier stages). Included in ‘3. Product’ is an Integrated Team process – which shows team members being involved at all stages of a modular project. A few caveats about the diagrams:

- There are many modular project and team structures, many more than these 3, but these were selected to compare contract vs. product, and linear vs. integrated team processes.

- Several marketing/project inception models are shown, from modular broker to in-house business development, to a more robust marketing/PR capacity within the modular company.

There’s a lot of work available in both the public and private multi-family housing markets. It’s important for the whole modular industry to have successful modular companies and successful modular projects. Integrated Teams and Product Thinking will ultimately help reduce unit cost. And reduced unit cost, coupled with successful, completed modular projects, will help grow the modular industry’s share of the US housing market and, get more people housed.

More from Modular Advantage

How Stack Modular Is Using AI to De-Risk Mid- to High-Rise Modular Construction

Artificial intelligence is no longer a future concept in modular construction—it is already reshaping how complex buildings are evaluated, designed, and delivered.

Gearing Up for the 2026 World of Modular

The Modular Building Institute (MBI) is bringing its global World of Modular (WOM) conference and tradeshow back to Las Vegas in April, and with it comes some of the industry’s best opportunities for networking, business development, and education.

New High-Rise Modular Apartment in Abu Dhabi Points Toward the Future of Multifamily Construction

Eagle Hills International Properties chose the BROAD Holon Building for a 16-story market rate apartment building in Zayed City, a central business district of Abu Dhabi. The project highlights the potential of the Holon system of volumetric modular construction to accelerate housing delivery.

MBI Announces First Ever Industry Apprenticeship Program in Collaboration with Marshall Advanced Manufacturing Center

MBI recently agreed to partner with Marshall Advanced Manufacturing Center (MAMC) to provide bona fide USDOL-approved apprenticeship programs for the industry.

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.