Lightweight & Beautiful 3D Printing

John McCabe is the Advanced Concepts Designer at Branch Technology, recently transitioning into that role from the Director of Marketing position at the company. McCabe has a Bachelor’s Degree in Architecture and a Masters in Industrial Design. He taught design at various institutions before moving to Branch in 2019.

Offsite Advantages

When you think of 3D printing buildings, you probably picture giant outdoor robot gantries “pooping out concrete” as John McCabe of Branch Technology puts it. Layer upon layer, gradually building up the walls “as has been done for millennia” — only now with robotics.

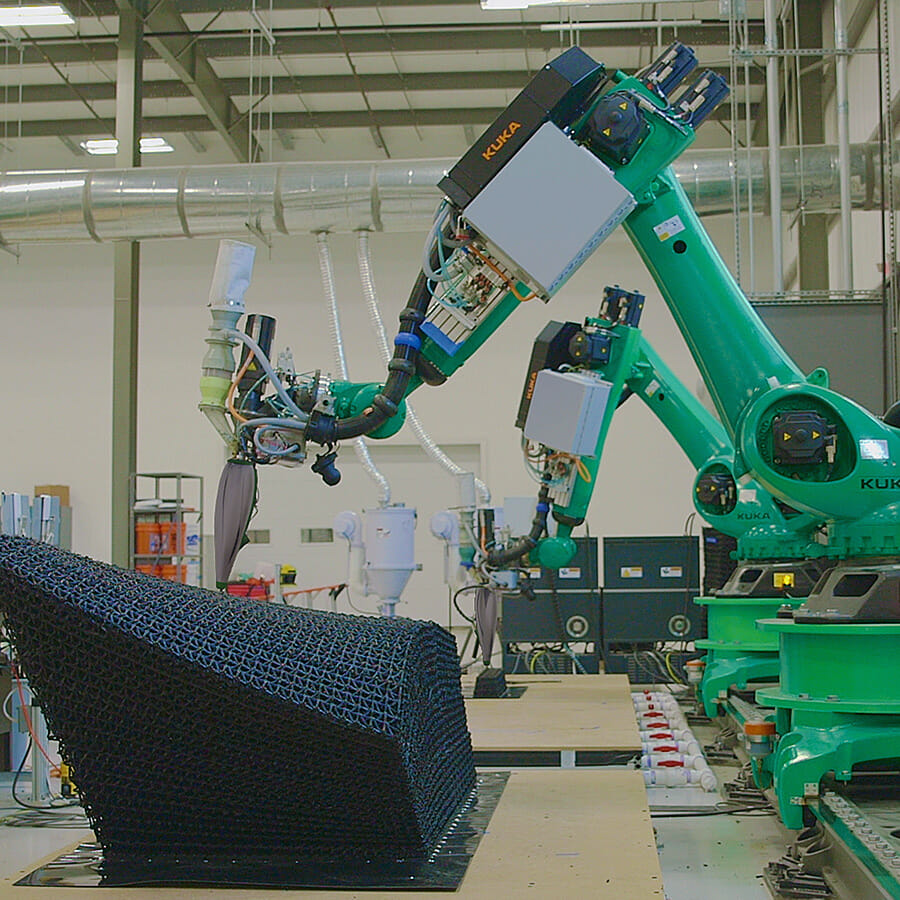

Branch Technology does 3D printing very differently, starting with printing offsite. “Printing onsite adds chaos, where there’s already a lot of safety issues,” says McCabe. Branch’s facility is far from chaotic — it’s a precise robotic ballet, with multiple projects being coordinated at the same time.

“In our facility, we have 12 foot robots printing a range of different types and scales of projects. One might be working on part of a parking deck, and another might be working on a bank, while another is printing something for the Department of Defense.”

Special Structures

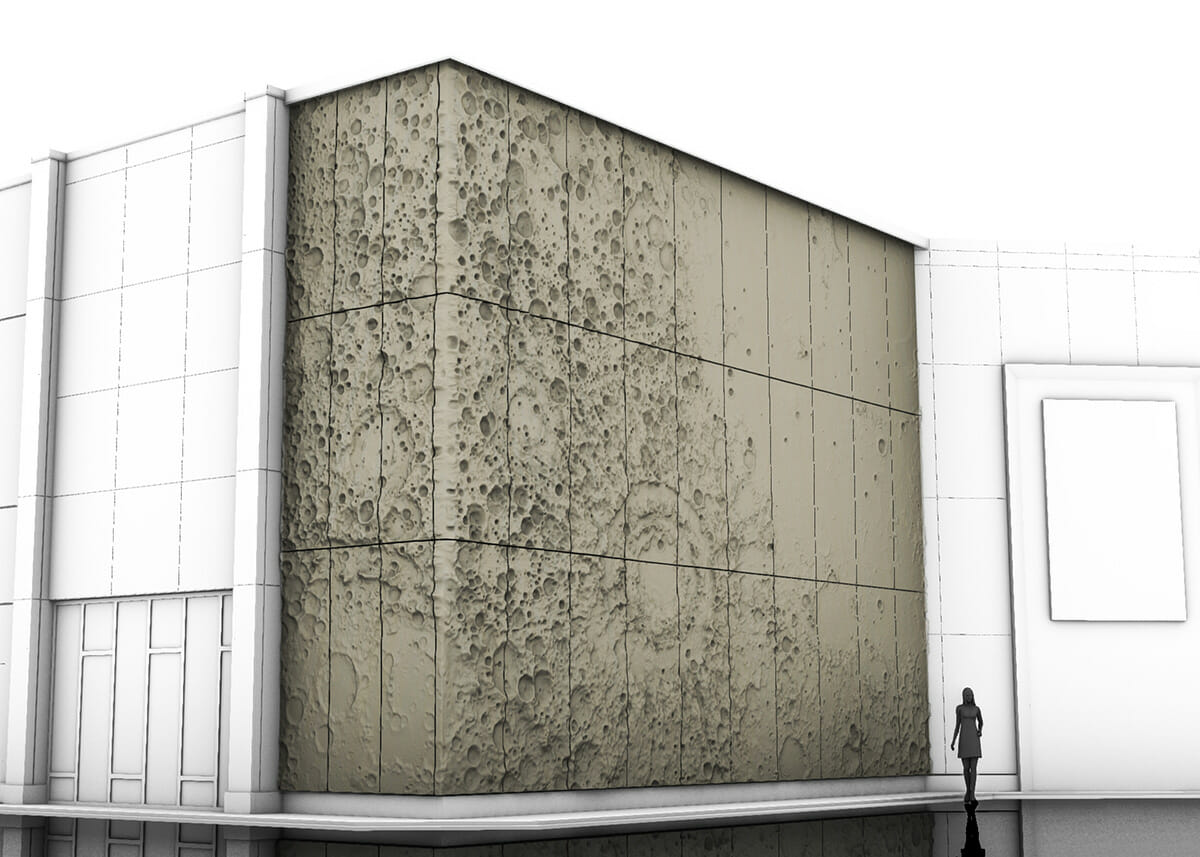

The structures that Branch robots print are also very different from layers of undifferentiated concrete. They are complex lattices that can be manufactured from various substances, have many different shapes and sizes, and be filled with different materials.

“Think about it. Very few buildings are made of only one type of material,” says McCabe. “Branch processes can combine complementary materials, increasing the resulting building’s capabilities and adding value for the client.”

Branch’s 3D printing “uses 20 times less material than other 3D printing methods, with almost no waste” and the resulting structures are many times lighter than a similar size structure printed with concrete. Although they’re light, the structures are designed for strength too. “A matrix we print that’s the size of a concrete block — but which is 90% air — will hold 2000-3000

pounds of compressive force,” explains McCabe. “When we fill that space with a customized foam, we can get almost 10,000 pounds of compressive strength.”

The lattice structures can be filled with various materials with different properties such as sound attenuation or thermal insulation. Sensors can be embedded within the materials to create a smart building.

Branch has printed a 3,000 square foot single story house. McCabe says it’ll be a few years before they can focus on building tall, self-supporting structures because the materials currently can’t compete with the capabilities of steel. “For the same reason, it’ll also be a long time before 3D printing with concrete can build taller than one storey.”

Founding and Focus

How was Branch founded? In 2013, there was a Kickstarter project for a 3D printing pen that could print in midair. Branch Founder and Chief Executive Officer, Platt Boyd, bought one and played around with it, attaching it to mini robots. He decided the idea had commercial potential in the construction industry, left the architecture firm where he’d worked for over 15 years, and moved to Chattanooga to found Branch. (Chattanooga and the surrounding area is a hotbed for innovation, especially in advanced manufacturing.)

“The company was embraced by the Chattanooga startup culture and the first employees were rockstars who came here from places like New York City and Boston. For the most part, they’re still here,” says McCabe. “We now have about 30 people working here and they’re the smartest group of people I’ve ever had the good fortune to work with.”

Because 3D printing is so versatile, Branch often received requests to make random things. But Boyd decided they needed to focus and the company went all-in on developing 3D printed façades. “They’re a great non-structural way to add a signature look to a building while still embracing the traditional construction trades.”

Labor

It’s a persistent refrain that it’s hard to hire young people to work in the construction industry, and labor shortages are a major problem. But working in the Branch facility is a far cry from a typical construction environment and Branch hasn’t had hiring problems.

“Construction companies can’t find talent,” says McCabe. “I’m privileged to work with a large, diverse group of young people who are very excited about robotics and the future of construction. They want to work in this industry.”

Off-World Construction

Branch has a team focused on developing solutions for the Department of Defense. “We’ve been taking speculative ideas and creating advanced manufactured products to fit their customized need,” says McCabe. “The kind of project ranges from a logistics solution for high-tech equipment, a building façade for onsite housing, or lightweight EMP-hardened expeditionary structures.”

They also work with the Air Force and the Space Force, leaning into this since 2017 when, out of a field of 77 global competitors, Branch won first place in the NASA Martian Habitat Challenge. The material they co-developed for printing the Martian habitat was the equivalent of 70% Martian soil, mixed with 30% recyclable mission waste such as bags and parachutes.

“The Space Force is expanding their knowledge and capabilities in off-world construction. We’ve been involved in developing zero-g and other-world concepts to save fuel and time, as well as to protect our service-people and equipment

from harm.”

The Future

Branch is partnering with real estate companies, developers, construction companies, and architecture firms. McCabe says that small companies trying to make their mark as well as big companies looking for efficiencies see value in Branch’s work.

“In the long term, we want a distributed factory network around the world that can print, fill, and finish structural and non-structural components for buildings of all scales,” says McCabe. “We have a roadmap to get there. We have some great partnerships in the pipeline and it’s going to blow some minds when we can finally talk about them!”

About the Author: Zena Ryder is a freelance writer, specializing in writing about construction and for construction companies. You can find her at Zena, Freelance Writer or on LinkedIn.

More from Modular Advantage

DORÇE Navigates Mountainous Terrain, Extreme Weather to Help Rebuild Türkiye

The February 6 earthquakes in 2023 were enormous. In response, DORÇE moved quickly, obtaining a government bid to help create housing and multipurpose structures—both temporary and permanent—for earthquake victims and laborers hired for reconstruction efforts.

Modern Desert Oasis: Building Reset Hotel the Modular Way

While the off-site construction part of the Reset Hotel project has been carefully controlled and with every necessity close at hand at BECC Modular’s factory in Ontario, Canada, the remote location of the project site has created additional challenges for the on site portion of the build.

Revisiting Yellowstone Canyon Village—a Groundbreaking Modular Construction Feat—Ten Years On

With such a short building period due to impending cold, it made the most sense for park developer Xanterra to pursue modular. Yellowstone’s high visitor traffic also required some odd transportation scheduling, as traffic from the West Yellowstone entrance determined the times when trucks could unload modules. Guerdon was up to the challenge.

Built for Brutal Cold, This Modular Office Building Shines

Houlton, the county seat of Aroostook County, Maine, is a small town with a population of about 6,000 residents. Situated along the border between the U.S. and Canada, what the town is most known for is bitterly cold winters. When the U.S. Border Patrol needed new office space, a modular building approach from Modular Genius offered the perfect solution.

Panel Replacement Adds Years of Life to Navy Vessel

Panel Built, Inc., recently replaced all the wall and roof panels on a two-story US Navy barge deck house that the company had originally installed 30 years ago, giving the vessel new life. Now, the commanding officer of the unit that uses the barge said the difference between the condition and appearance from when the barge left their facility to when the project was complete was beyond his expectations of what was possible.

True Modular Building Seeks to Revolutionize Housing. It’s Next Stop: MBI’s World of Modular Europe

True Modular Building (TMB) specializes in crafting attainable, eco-friendly, and comfortable build-to-rent (BTR) housing with modern designs and customizable features, ensuring that residents feel at home both today and tomorrow.

From Toronto to Suriname: A Global Modular Building Story

When I AM Gold – a Canadian gold mining operation based in Toronto, Ontario – wanted to expand its mining operations in Suriname, it knew it would also need to expand its infrastructure. More specifically, they needed to build a mechanical services compound that would allow their local crews to maintain and equipment critical to their mining operations. They also knew that it would be a challenge.

There Were a “Sea of Challenges” for this Modular, Island Development

Question: Can modular construction be used to build a series of affordable, unique housing buildings, all styled to look like they were built in 1845, on an

island that caters to the wealthy? The answer is, of course, yes, but how the

team at Signature Building Systems and KOH Architecture got there is quite a story.

America’s Construction Economy: A Race Against Time

If the economy has been able to handle higher interest rates thus far, undoubtedly it will be able to manage the lower interest rates to come. But many economists are pointing out that the Federal Reserve may already be too late to the game. While they gradually reduce interest rates, the U.S. economy could quickly decelerate, at least based on theoretical grounds if not on the most recent data releases, culminating in that long-predicted recession. Only time will tell.

Top Five Benefits of Modular Office Space

Modular office spaces are transforming how businesses think about their work environments. These innovative structures offer a mix of flexibility, efficiency, and sustainability, making them a smart choice for companies looking to gain an advantage.