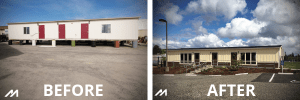

Repurposed for a Second Life: Renovated Reuse Case Study

The original 24’x64’ building was built by Modern Building Systems in 1996 to serve as daycare facility for the Northwest Regional Educational Service District (ESD) in Forest Grove, Oregon. In 2016 the building was no longer needed and donated to the local Habitat for Humanity chapter by Modern Building Systems. They purchased and removed the building at no cost to the ESD. It then was transformed into a beautiful newly renovated daycare facility for Family Nurturing Center to expand services as a satellite campus in Phoenix, Oregon. The building now houses daycare services for 28 children and families.

The newly renovated daycare space is comprised of two classrooms, men’s and women’s restrooms, an office space, and kitchen. Modern worked with Family Nurturing Center board member and architect, Brian Westerhout to redesign the building to fit the needs and desires of the daycare. Additional walls were installed near the restroom and hallway area between the classrooms was widened to allow for greater accessibility. Old windows were replaced by large 8/0 x 6/0 premium vinyl windows to bring in more sunlight into the room. While the upgrades of marmoleum flooring and casework adds additional visual appeal throughout the building. The new exterior features include: bright custom colors of fiber cement siding and trims. Roofing and welded hollow metal doors were upgraded as well.

Materials from the original builder were used whenever possible. By utilizing the original structure as much as possible, the result was less construction and demolition waste in the landfill. Basically, the client recycled a whole modular building. A brand new high-efficient gas Bard mechanical unit was installed on the building to upgrade the building.

The Family Nurturing Center is a nonprofit that is part of Oregon’s innovative and comprehensive response to support children and families in crisis and therefore operates on razor thin budgets. Modern, long with local contractors, gave discounts and donations to help make this project a reality. By utilizing a used building and renovating it, the client saved thousands of dollars compared to a new building to the same design and specifications.

This article originally appeared in the Modular Advantage Magazine - Fourth Quarter 2018 released in November 2018.

More from Modular Advantage

Behind the Design of Bethany Senior Terraces, NYC’s First Modular Passive House Senior Housing Project

As more developers seek to meet new regulations for energy efficiency, the team at Murray Engineering has set a new record. With the Bethany Senior Terraces project, Murray Engineering has helped to develop NYC’s first modular structure that fully encompasses passive house principles — introducing a new era of energy efficiency in the energy-conscious city that never sleeps.

How LAMOD is Using Modular to Address Inefficiency, Sustainability, and the Future of Construction

As developers, designers, and contractors seek to understand the evolving needs of the modular industry, no one is as well-versed in the benefits of going modular as Mārcis Kreičmanis. As the co-founder and CBDO of LAMOD in Riga, Latvia, Mārcis has made it his ultimate goal to address the inefficiencies of traditional construction.

From Furniture Builder to ‘Activist Architect’: Stuart Emmons’ Unique Journey

Stuart Emmons was fascinated by buildings at a young age. He remembers building sand cities with his brother during trips to the Jersey shore. His father gave him his first drawing table at the age of ten. Today, he is an experienced architect who received his FAIA in June 2025. The road he took is unique, to say the least.

Forge Craft Architecture + Design: Codes, Contracts, and Intellectual Property

Founding Principal and Director of Modular Practice for Forge Craft Architecture + Design, Rommel Sulit, discusses the implications of codes, contracts, and intellectual property on

modular construction.

Eisa Lee, the “Bilingual” Architect

Now as the founder of XL

Architecture and Modular Design in Ontario, Canada, she applies not just her education as a traditional architect but an entire holistic view on modular design. It’s this expansive view that guides her work on being a true partner that bridges the gap between architects and modular factories as they collaborate on the design process.

Tamarack Grove Engineering: Designing for the Modular Sector

The role of a structural engineer is crucial to the success of a modular project, from initial analysis to construction administration. Tamarack Grove offers structural engineering services — project analysis, plan creation, design creation, and construction administration — for commercial, manufacturing, facilities, public services, and modular. Modular is only one market sector the company serves but it is an increasingly popular one.

Engineer Masters the Art of Listening to His Customers

Since founding Modular Structural Consultants, LLC. in 2014, Yurianto has established a steady following of modular and container-based construction clients, primarily manufacturers. His services often include providing engineering calculations, reviewing drawings, and engineering certification

Inside College Road: Engineering the Modules of One of the World’s Tallest Modular Buildings

College Road is a groundbreaking modular residential development in East Croydon, South London by offsite developer and contractor, Tide, its modular company Vision Volumetric (VV), and engineered by MJH Structural Engineers.

Design for Flow: The Overlooked Power of DfMA in Modular Construction

Unlocking higher throughput, lower costs, and fewer redesigns by aligning Lean production flow with design for manufacturing and assembly.

Choosing the Right Ramp

Modular construction offers a compelling alternative to traditional methods for designing and building ADA and IBC-compliant entrances. By addressing the challenges of traditional construction, such as time-consuming processes, unavailable specialized labor, and variable field conditions, modular solutions provide a more efficient, cost-effective, and reliable approach.