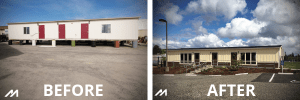

Repurposed for a Second Life: Renovated Reuse Case Study

The original 24’x64’ building was built by Modern Building Systems in 1996 to serve as daycare facility for the Northwest Regional Educational Service District (ESD) in Forest Grove, Oregon. In 2016 the building was no longer needed and donated to the local Habitat for Humanity chapter by Modern Building Systems. They purchased and removed the building at no cost to the ESD. It then was transformed into a beautiful newly renovated daycare facility for Family Nurturing Center to expand services as a satellite campus in Phoenix, Oregon. The building now houses daycare services for 28 children and families.

The newly renovated daycare space is comprised of two classrooms, men’s and women’s restrooms, an office space, and kitchen. Modern worked with Family Nurturing Center board member and architect, Brian Westerhout to redesign the building to fit the needs and desires of the daycare. Additional walls were installed near the restroom and hallway area between the classrooms was widened to allow for greater accessibility. Old windows were replaced by large 8/0 x 6/0 premium vinyl windows to bring in more sunlight into the room. While the upgrades of marmoleum flooring and casework adds additional visual appeal throughout the building. The new exterior features include: bright custom colors of fiber cement siding and trims. Roofing and welded hollow metal doors were upgraded as well.

Materials from the original builder were used whenever possible. By utilizing the original structure as much as possible, the result was less construction and demolition waste in the landfill. Basically, the client recycled a whole modular building. A brand new high-efficient gas Bard mechanical unit was installed on the building to upgrade the building.

The Family Nurturing Center is a nonprofit that is part of Oregon’s innovative and comprehensive response to support children and families in crisis and therefore operates on razor thin budgets. Modern, long with local contractors, gave discounts and donations to help make this project a reality. By utilizing a used building and renovating it, the client saved thousands of dollars compared to a new building to the same design and specifications.

This article originally appeared in the Modular Advantage Magazine - Fourth Quarter 2018 released in November 2018.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.