The Use of MS POLYMER™-Based Sealants and Adhesives in Modular Building

Luc Peeters is the R&D Manager, Performance Polymer Solutions Vehicle | MS Polymer Division at Kaneka.

One of the major advantages of modular building is construction in a factory under controlled conditions. In many cases, an assembly line system is implemented that moves the modules through the factory depending on the construction stage. Hence, the modules are subjected to more movement and vibrations compared to traditional construction methods. In the final stage, the modules are transported on a truck to the building site, again subjecting the modules to vibrations and shocks. It can result in cracking of joints and adhesives leading to cracking or falling of tiles or other materials. As a result, a lot of assembly and finish work has to be done on the building site.

MS POLYMERTM, a silane modified polymer (SMP), was developed in Japan as base resins for sealants and joint fillers to protect buildings against earthquakes—simply put: the SMP provides a high elongation and elastic recovery to cope with vibrations and movement of the building. Since the rollout of that initial product, additional adhesives were specifically developed for tiling—for instance, in railway stations where cementitious adhesives will crack over time and tiles can fall off the walls.

Keeping these properties in mind, the SMP-based adhesives and sealants are ideal products for the construction of modular buildings and provide solutions for both exterior and interior adhering and sealing.

Fig. 1 Cut-through of the outer wall

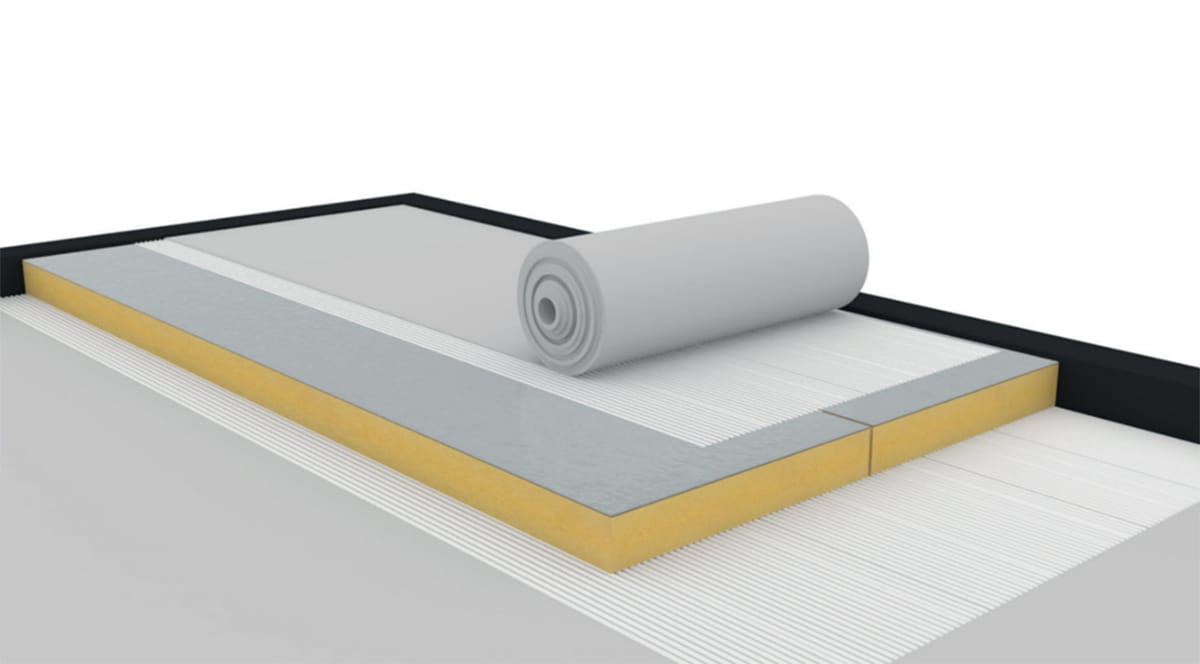

Fig. 2 Cut-through of a flat roof

Exterior Applications of SMPs

Exterior walls can vary widely, but many consist of different layers starting with a wooden or fiber cement panel on which insulation panels are adhered. These connections can be made stronger by using SMP panel bonding adhesive. The wall can then be made even more air- and water-tight by sealing it off with a panel adhered with a tackified SMP foil adhesive. The final finishing of the wall can be done with stone strips, as conventional bricks are too heavy, or wooden or composite panels by using a SMP stone strip adhesive or panel bonding adhesive or a high tack adhesive. To prevent any cracking of the outer wall, an expansion joint with a low modulus sealant can be applied.

When we then take a look at the roof, which are often flat in modular buildings, again often find wooden panels with insulation panels adhered on top with an SMP-based insulation or high tack adhesive. For covering large areas there are already sprayable adhesives available. The roof can then be finished with an EPDM, TPO, or bitumen membrane which can all be adhered with SMP-based adhesives. The solid membrane can also be substituted with liquid applied membrane which can be applied with a roller or squeegee.

Any pipes or gutters can still be sealed with a detailed roof sealer.

Interior Applications of SMPs

Interiors can vary widely, but there are many ways the SMPs can help secure and seal various components. Floors, for example, are often based on panels with a wood laminate, parquet, or LVT floor adhered. For all these types of flooring, specific SMP based adhesives are available.

To prevent cracking and distribute vibrations and movements, elastic joint sealants with excellent recovery are required for sealing the skirt board, but also for sealing the joints between the plaster, wood-, or cement fiber-based panels.

For all the assembly of racks, sinks, etc., general purpose adhesives and sanitary sealants are available.

For wet areas such as bathrooms and showers, specially-designed SMP products need to be used. One option is a watertight coating based on newly-developed low viscosity SMP grades which can be applied under tiles. Kaneka has also developed a new reactive tile adhesive that passes EN-12004-RT2, which up to now was only possible with epoxy adhesives. To enable even more time saving, a 2-in-1 coating was developed which combines the watertight coating and the tile adhesive in one product.

Testing the Strength of SMPs

During assembly, the modules are moved through the factory, and once construction is complete, the modular building is transported by truck to the building site. During this movement and transportation process, the building is exposed to vibrations and shocks, which can result in issues such as cracked or detached tiles.

To demonstrate that elastic SMP-based sealants and adhesives can effectively prevent tile cracking and detachment, a truck transport simulation was conducted in accordance with ASTM D4169-23. In this test, a test piece with tiled panels was placed on a vibration table and subjected to a controlled vibration cycle.

The cycle included:

- 15 minutes of truck vibration at low level (random, 1–200 Hz, control: 0.40 Grms)

- 15 minutes at medium level (random, 1–200 Hz, control: 0.54 Grms)

- 5 minutes at high level (random, 1–200 Hz, control: 0.70 Grms)

This test cycle simulates the vibrations experienced over a 400 km truck journey in real-world conditions.

The test piece consisted of two OSB panels and two fiber cement boards. Four different adhesives were applied, three cementitious and one SMP-based. On each type of board, eight white ceramic tiles (20 cm x 20 cm) were adhered using the different adhesives without applying any primer (see Fig. 4).

The results shown in table 1 show that the SMP-based adhesive offers the best performance for modular building applications. It maintains strong adhesion even on challenging substrates such as OSB panels, without the need for a primer, and withstands long-distance transportation without compromising the integrity of the tile installation.

Table 1: Test results of truck transport simulation (ASTM D4169-23)

Fig. 3 Cut-through of a shower wall

Fig. 4 Picture of the assembled test piece

Fig. 5 Test piece during the vibration test

Conclusion

After taking a closer look at a modular building process, it becomes clear that both the interior and exterior can be completely constructed and assembled by using MS POLYMERTM-based sealants and adhesives. These products combine flexibility and elastic recovery with excellent adhesion to different substrates and have already shown their usefulness in traditional construction. Now it’s time for them to be put to use in the modular construction industry.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.