Inside College Road: Engineering the Modules of One of the World’s Tallest Modular Buildings

Michael Hough is the Director of MJH Structural Engineers.

The Missed Opportunity in Modular Design

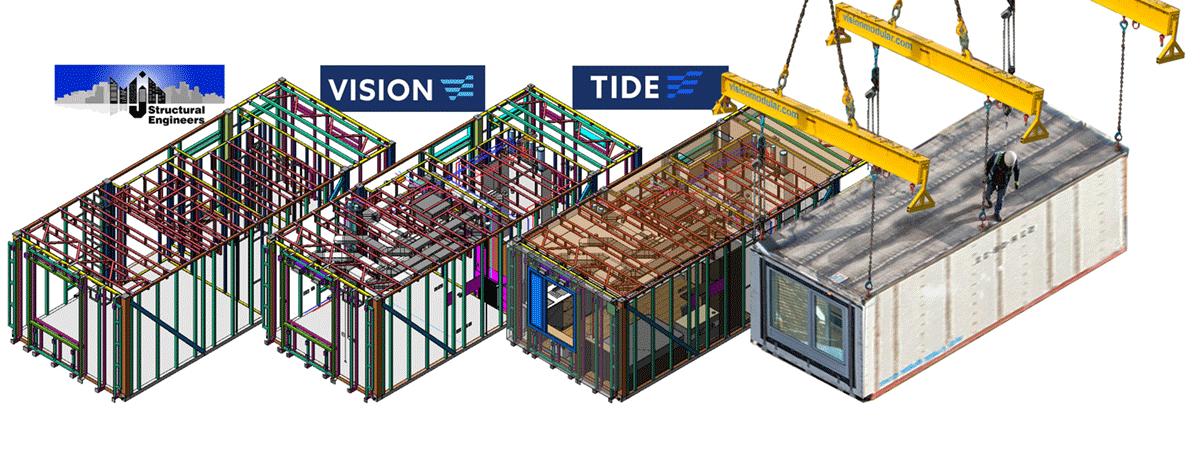

College Road is a groundbreaking residential development in East Croydon, South London by offsite developer and contractor, Tide, its modular company Vision Volumetric (VV), and engineered by MJH Structural Engineers. The scheme comprises two of the world’s tallest modular buildings delivering almost 1000 new homes. A 35-storey tower provides 120 affordable homes, and a 50-storey tower provides 817 co-living homes, one of the largest co-living developments across the globe. Both have significant amenity spaces and a double level basement. Fundamentally, this development was delivered on a constrained 2,000 m2 site in only 28 months from start to finish due to its modular delivery. The towers were constructed using 1725 Vision modules wrapping two concrete cores, placed on a four-storey concrete transfer structure, containing amenity facilities for the building.

System Description

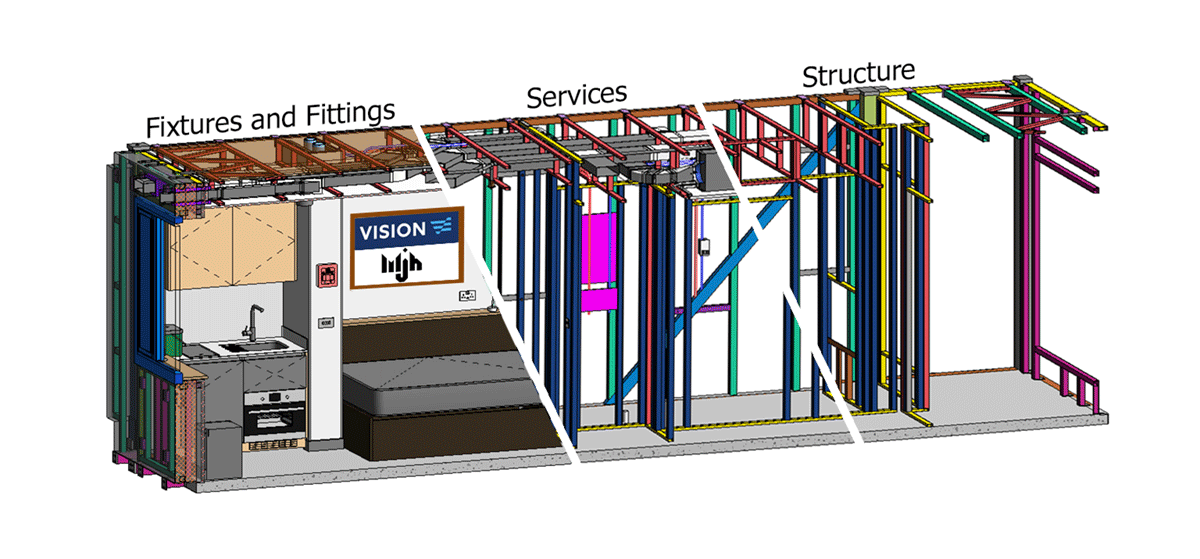

This project was designed by MJH, Tide, Vision, and HTA architects with a modular solution in mind from the outset maximising the system abilities at an early stage to ensure efficiencies. The flexibility of the Vision system allows the full floor plate outside of the central core to be constructed as individual interconnected room enclosing modules.

Each module is manufactured from a series of wall panels, a floor and ceiling. The wall panels are assembled with steel frames welded between the main structural members. These walls are engineered to provide the structure for the final building with considerations for the temporary stages of construction. The walls need to be strong and stiff enough for the handling, moving and resulting forces that occur before full assembly into 3D modules.

Once assembled into modules the lifting and handling must consider the stiffness of the assembled components and prevent distortions. A concrete floor is poured in the factory and adds stiffness and weight to the module.

Design and Loads

Each concrete slab is engineered for the specific module based on span and openings with local details to transfer connection forces into the concrete slab. In the permanent position the slabs only have tension on the lower surface, but tension may occur on the upper surface in the temporary stages. If a module overhangs a truck bed, then the slabs may need to cantilever either to the side or off the back of the trailer. With modular construction the design loading and situation may not always arise on site or in the completed building.

A photo of College Road, left, under construction. Photo: Michael Hough.

The critical forces on various members within a modular system occur at different times. Modular walls, particularly internal to the building perimeter, are sheltered from load in their permanent location. The design case may be the wind due to transportation or during placing on site where they are exposed. On the trailer there may be pressures and suctions generated from the speed that far exceed those experienced-on site.

For the College Road height of construction, we use wind tunnel assessments that identify the wind pressures and suctions. These are mainly used to inform the stability design but may provide local forces also.

The design vertical loads vary throughout the height of the building and are assessed by way of detailed structural modelling. MJH’s design considers each column by storey individually so each column in each position in the building is engineered to be efficient. This is essential to manage the steel tonnage in tall construction. The analysis forces are taken from the building model and considered together with other design considerations outside of standard engineering design programs as these do not consider all the requirements for modular design. Designed sizes are added back to the model and an iterative design process results in compatible design and analysis sizes.

There is a complex distribution of load in modular construction related to the stiffness of the floor and wall construction which is influenced by the stiffness of the floor in particular. Further effects occur in tall structures where the stiffness of the foundation and transfer structure may influence the distribution of axial load through the building. To further investigate the efficiencies in the design we undertake staged construction analysis of the building as the modules are placed level by level. This allows an understanding of the connection forces, that arise as the modules are placed, and the loading conditions change.

There are various elements of the module that are engineered for their intended use, and which do not vary significantly throughout a building. The ceiling supporting members have a reasonably standardised design base on their span, the load conditions do not vary by story or by room. These members support the internal finishes, services, external finishes for the temporary transportation and placing stages and need to be stiff and strong enough to allow personnel access during the placing operation. It is likely that site access will dictate the design of these members as this will be the highest loading and any brittle finishes will be in place, so the deflections need to be restricted. Similar design requirements occur for infill studs in walls where they do not form a main element of the engineered completed structure.

There are many items in a modular system that may be designed to reach a certain level of capacity that is mostly sufficient and requires minimal further assessment. Where capacities are exceeded then additional solutions are required for these areas. Determining the most efficient construction to meet the majority of requirements is essential to efficient manufacture.

Automation and Manufacturing

Vision set up their modular system and the manufacturing process to encompass as broad a range of sizes and shapes as they possibly could. This allows greater architectural freedom in maximising the modular content of a development but also if utilised to a high level can put pressure on the delivery of the system throughout the design, detailing, procurement and manufacture.

Over the years in MJH we have worked to add levels of automation into our workflows through computational engineering and coding. Standardisation within the system is at a component level, where we build the modules from elements that are well understood into modules that vary significantly. Automation in the design and detailing stages allows reductions in the critical path time leading to manufacture especially where there are large numbers of variations in modular layouts on a floor plan.

Complex Loads

DfMA is a powerful tool — but only when wielded in service of Lean flow. The modular industry can’t afford to treat design and manufacturing as separate domains. When they’re integrated, factories hum, projects deliver on time, and customers get exactly what they were promised.

If we want modular construction to fulfill its potential, we must move beyond designing for assembly and start designing for flow. That means embedding flow principles in the earliest design conversations, empowering production teams to shape those designs, and viewing every product through the lens of factory fit and sequencing.

The future of modular isn’t just smarter design — it’s synchronized design. And that begins with DfMA that flows.

Fire

Fire considerations in taller modular construction falls outside of the practical area of previous fires, thankfully we do not have experience of real fires in modular buildings. As a result, there are additional assessment criteria to assess the consequences of high temperatures in one area of a building adjacent to another where ambient temperature prevails. In traditional construction structural members are more likely to be shared between these areas but in modular construction, whether good or bad, the structure is mostly separated either side of a compartment wall.

Extreme temperatures will try to expand structural members such as columns and this expansion is resisted by the building weight, the connectivity to other elements of structure and the adjacent strength of cooler members. Thermomechanical models are created and analysed for all our modular buildings to assess the movements and forces, and these are based on fire tests of full modules, walls, floor assemblies and components and on stiffnesses generated in tests both digital and physical. These assessments do not change our overall building designs and layouts for the Vision system but offer high levels of confidence in this form of construction due to the extreme temperatures used in the modelling beyond what is practically achievable in buildings.

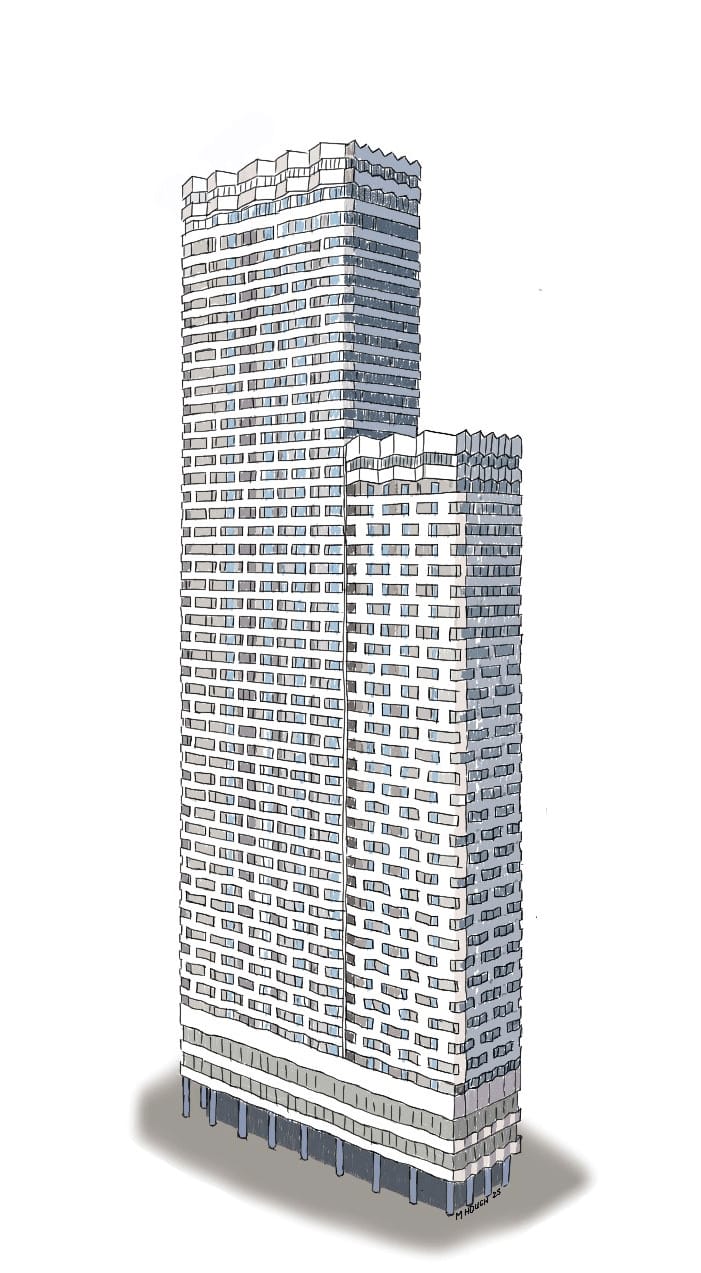

An exterior sketch of College Road.

Collaboration

A key enabler of this design flexibility and efficiency is the close collaboration between MJH, Vision, and our fabrication partners. The full structural model is developed in Tekla Structures and shared in real time with our steel fabricator, allowing fabrication details to be coordinated directly from a live, centralised model. This open exchange of information removes silos and ensures all parties are working to the latest design data. In parallel, Vision models and coordinates all architectural and MEP elements within Autodesk Revit, which is continuously aligned with the structural model to identify and resolve potential clashes ahead of manufacture.

This integrated digital workflow, underpinned by robust BIM coordination, ensured a high level of precision and consistency across the supply chain throughout the delivery of the College Road project.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.