GrayWolf: Building the Future of Modular Data Centers to Power the AI Revolution

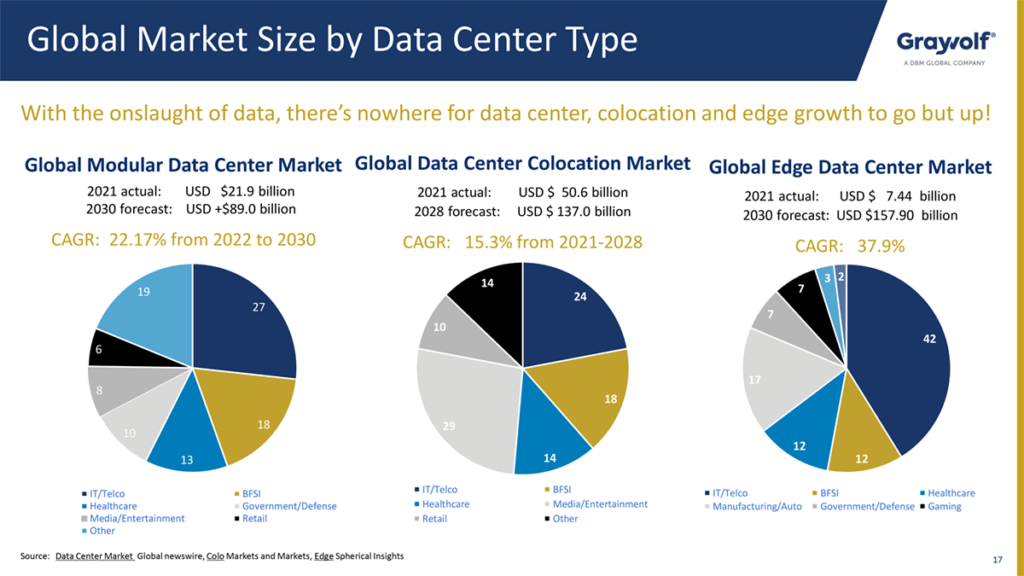

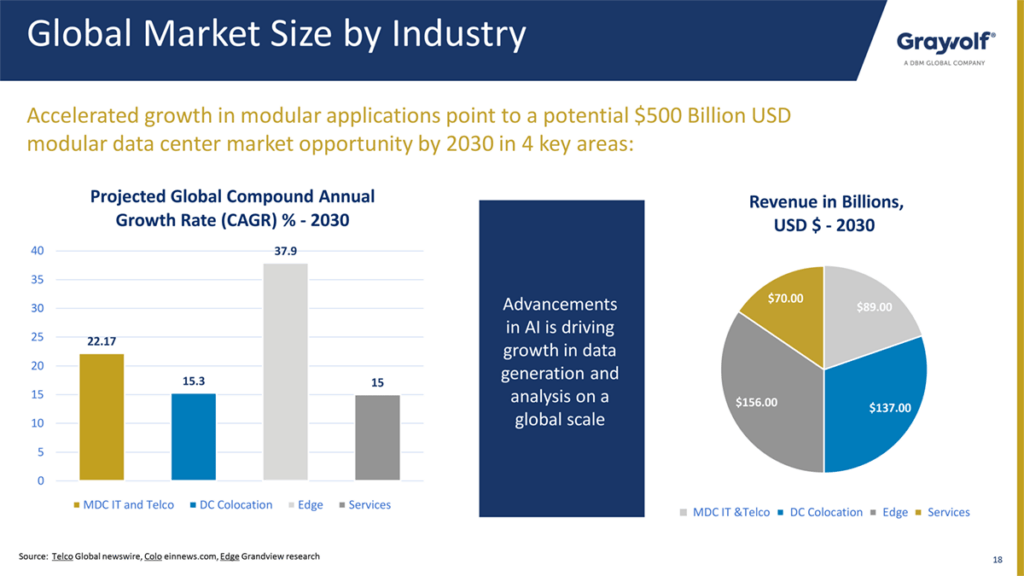

The growth of artificial intelligence (AI) and cloud-based applications has created an urgent need for data centers capable of managing massive amounts of data. As businesses across industries increasingly rely on digital infrastructure to power their AI tools, the demand for data centers has skyrocketed. One company playing a key role in meeting this demand is GrayWolf - a construction company that has taken on the challenge of modularity by building and deploying scalable, efficient, and sustainable data centers and data center components for today’s tech-driven world.

With deep industry knowledge and a forward-thinking vision, GrayWolf is redefining how data centers are built and paving the way for new possibilities in the modular construction industry. Illuminating the intersection between traditional construction, modularity and technology, Ron Mann, the Senior Vice President at GrayWolf, shared insights into how their work is pushing the boundaries of modular construction and supporting industries that rely on data centers, AI, and cloud-based technology.

Ron has over 25 years of experience in product design, project development, and manufacturing. He helped develop one of the first eco-friendly containerized data centers in the early 2000s. His unique understanding of technology, data center design and modular construction helps him align client expectations, delivering sustainable solutions for data center, edge, cloud, colocation, and other customized modular construction at GrayWolf.

The Impact of AI on Data Center Infrastructure

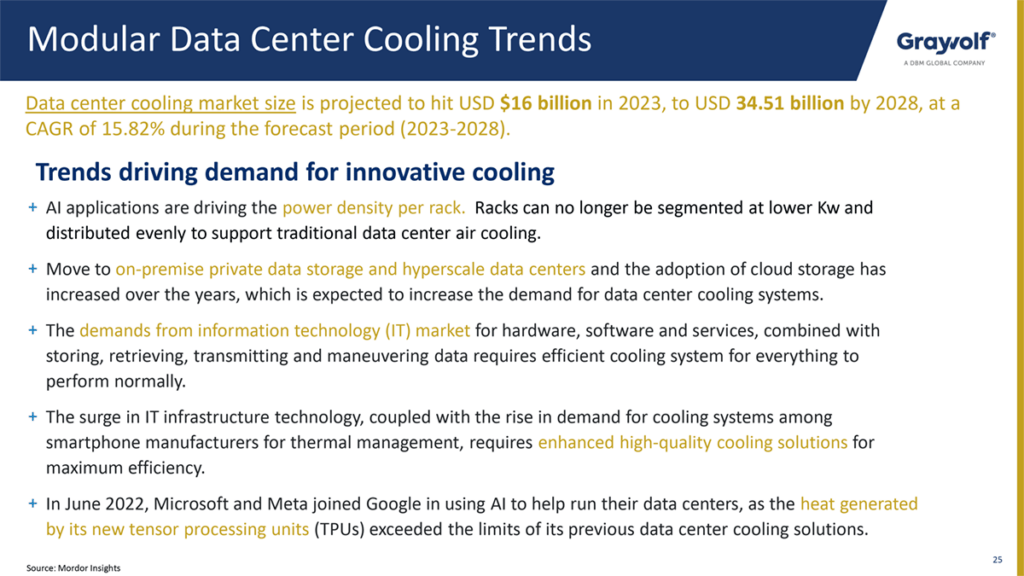

The rise of AI has significantly changed the game for data centers. Traditional data centers that handled power demands averaging 10 kilowatts per rack now face challenges with AI workloads that require 50, 60, or even 100+ kilowatts per rack. Unlike other applications, AI cannot be distributed across multiple racks similarly, so concentrated power and cooling are now essential.

As AI becomes more prevalent, it’s pushing data centers to their limits, making retrofits or completely new builds necessary to handle these higher power densities. The cost of these upgrades is substantial, and many data centers now find themselves with underutilized space due to the excessive power requirements of AI applications.

The Shift to Modular Data Center Construction

As the demand for more efficient, scalable, and rapid deployment of data centers grows, there has been a significant shift in how these infrastructures are designed and implemented. One of the most notable trends in recent years is the rise of modular construction. This shift isn’t only about speed but also the practical and financial benefits that come with it, especially when considering higher IT power requirements.

“Data centers are growing quickly to keep up with increasing demand for data storage and processing so it’s no surprise they will test out new technologies and approaches for data center development and deployment, which means more innovation and yes, risk-taking to be able to support new IT technologies coming online. Data Centers need to scale, and they need to do it fast,” says Ron. “Traditional construction methods are often too slow and costly to meet the rising demand.”

Speed and Cost Advantages of Modular Construction

While speed is one of the primary reasons for the increasing popularity of modular construction, the benefits go beyond just quicker deployment. One of the key advantages of modular construction is optimization of capital investment. For example, if a company wants to build a 20-megawatt data center but only needs 10 megawatts immediately, modular construction allows them to build what they need now and expand later. This eliminates the issue of capital being tied up in underutilized infrastructure, which is a common challenge with traditional construction methods. Instead, a company can simply add modules or modular elements as IT capacity needs increase.

The Flexibility of Modularity: From Data Centers to Mechanical Plants

The versatility of modular construction is another key advantage. It’s not just data centers that can benefit from modularity; entire buildings, mechanical plants, and other complex infrastructures can be designed using modular principles. In some cases, structures are built with dozens of modules that fit together, providing a streamlined and efficient way to assemble large-scale facilities.

One example is constructing large white space areas for data centers, where multiple 40-foot by 11-foot units are assembled on-site to scale as needed for the application. This method is highly efficient and is especially popular with telecommunications companies, needing to locate infrastructure in unique or remote locations. The flexibility of modular construction allows it to be applied across multiple industries and multiple use cases, making it a versatile solution for different project needs.

Simplifying Compliance and Accelerating Project Timelines

Another significant benefit of modular construction is the potential to simplify building code and regulatory compliance. Since many modular units can be considered devices rather than habitable buildings, they can often bypass lengthy approval processes or AHJ scrutiny. “A UL2755 rating as an example, identifies a modular IT unit addressing safety, power distribution, structural integrity and transportation elements, which can accelerate deployment by reducing the number of approvals required,” explains Ron. “This is especially useful for IT modules, where speed and efficiency are paramount.”

By planning modular projects correctly, businesses can save both time and money. Pre-assembled sections, such as electrical, conveyance and plumbing systems, can be delivered to the site and quickly integrated with traditional site construction. This reduces the time needed for on-site labor trades, making them available in other areas, and streamlines the overall project timeline.

The Impact of Modularity on Energy Efficiency

One of the most notable differences between traditional and modular data centers especially in the lower rack power ranges, is the impact on energy efficiency. In a traditional data center, large areas are often cooled, regardless of the number of servers being used. This results in wasted energy, as excess capacity is cooled unnecessarily. If more power and cooling is required, the data center will most likely need significant retrofitting to gain efficiencies such as cold and hot aisle containment or other “spot cooling” upgrades.

Modular data centers, on the other hand, are designed to optimize power and cooling of specific racks or sections of IT at the required application densities. This targeted cooling not only reduces energy consumption but also makes for increased efficiency especially when coupled with other types of cooling technologies that are more easily added to a modular solution such as direct chip cooling.

GrayWolf Meets the Demands of Data Centers

With over 15 years of experience in the industry, GrayWolf is known for its customer-centric approach. Working closely with clients to build modularity into many facets of data center construction, they aim to understand each customer’s specific needs and goals, ensuring that each modular solution is tailored to meet those requirements. GrayWolf offers end-to-end services that help make the modular construction process seamless - from design/design assist to build, factory integration and final assembly and commissioning in the field.

“Every client has unique needs, whether it’s cooling systems, power requirements, structures, or scalability,” says Ron. “We provide modular solutions at whatever level businesses need. Modularity lets us meet customers where they are today and allows them to scale as they grow. It’s all about building with the future in mind.”

By delivering these tailored solutions, GrayWolf is at the forefront of supporting AI’s growth and ensuring companies can expand their infrastructure to meet the demands of today and tomorrow. “We’re building the foundation for what AI can do, with data centers that grow alongside businesses’ evolving technology needs,” says Ron.

Leading the Charge in Innovation

One of the most compelling aspects of GrayWolf’s modular solutions is how they intersect with broader trends in innovation. As Ron stated earlier, data centers are growing quickly to keep up with increasing demand for data storage and processing, and it’s no surprise they will test out new innovative technologies. This means more risk-taking of new modular designs and approaches that will also have broad applications in other markets and industries. GrayWolf’s commitment to embracing these innovations is central to its long-term strategy. This not only benefits the company but also creates opportunities to influence other sectors that will inevitably adopt modularity.

“Being at the forefront of everything that’s happening in the world... for the next few years, if not more,” Ron remarked, “is a testament to GrayWolf’s leadership in driving change. Our expertise in modular design is an example of how companies can challenge and complement traditional methods to create new, sustainable solutions for the future.”

Passion Meets Purpose

Ron and his team at GrayWolf are not just participants in the modular revolution; they are dedicated pioneers. “I’m passionate about it,” Ron shared, “I think it is one of the last emerging areas of innovation as you are seeing the combination of the best of product development and manufacturing merging with the best of site construction and integration with solutions that actually make a difference.”

That passion fuels GrayWolf’s vision for the future, where they aim to create meaningful change in how buildings are designed, constructed, and operated. “How many times do you get to be in an industry where you can actually help create a new way of doing things?” Ron asks. This unique opportunity to innovate motivates the entire team at GrayWolf, driving them to explore uncharted territory in modular solutions.

A Vision for the Future of Modular Construction

GrayWolf is not just focused on the present. Their sights are set on the future, where they aim to be leaders in transforming the construction industry through modular innovation. As Ron eloquently put it, “We just have a lot we can do. So, it’s a great opportunity.”

With their deep expertise, GrayWolf is committed to offering modular solutions across industries, helping to shape the future of construction. As modular construction continues to grow in importance, companies like GrayWolf will play a crucial role in driving sustainable, flexible, and efficient building practices for years to come. “Data centers are just the beginning,” Ron says. “Our goal is to expand modularity into all industries. We’re not just here to build data centers - we want to help reshape how industries approach construction and infrastructure.”

“We see a future where modularity becomes the standard, not the exception,” Ron states. “It’s faster, more efficient, and more sustainable. As industries like AI continue to grow, they’ll need infrastructure that can grow with them. That’s where modular construction comes in.”

About the Author: Karen P. Rivera is a freelance writer and editor with a passion for storytelling. She is a former United Nations-based reporter, with experience covering international breaking news, venture capital, emerging healthcare tech, and the video game industry.

More from Modular Advantage

How Stack Modular Is Using AI to De-Risk Mid- to High-Rise Modular Construction

Artificial intelligence is no longer a future concept in modular construction—it is already reshaping how complex buildings are evaluated, designed, and delivered.

Gearing Up for the 2026 World of Modular

The Modular Building Institute (MBI) is bringing its global World of Modular (WOM) conference and tradeshow back to Las Vegas in April, and with it comes some of the industry’s best opportunities for networking, business development, and education.

New High-Rise Modular Apartment in Abu Dhabi Points Toward the Future of Multifamily Construction

Eagle Hills International Properties chose the BROAD Holon Building for a 16-story market rate apartment building in Zayed City, a central business district of Abu Dhabi. The project highlights the potential of the Holon system of volumetric modular construction to accelerate housing delivery.

MBI Announces First Ever Industry Apprenticeship Program in Collaboration with Marshall Advanced Manufacturing Center

MBI recently agreed to partner with Marshall Advanced Manufacturing Center (MAMC) to provide bona fide USDOL-approved apprenticeship programs for the industry.

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.