Silverking Student Housing, Selkirk College

Architectural Excellence

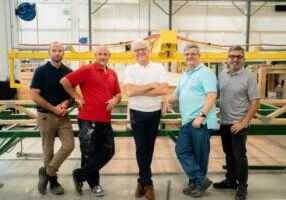

ROC Modular was proud to deliver a much-needed new permanent modular Student Housing Residence for Selkirk College, located at the Silverking Campus in Nelson BC. The project is a 3-storey, 12-module 38-student bed building with a mass-timber main common area for student amenities. Modular construction was chosen as the ideal solution to provide high-quality, fast-track affordable housing for students. The project is located in Beautiful Nelson BC, a community in the Kootenay region of Interior British Columbia, Canada. The project houses students attending Selkirk College, each dorm unit has a shared washroom, and the building also has a number of communal areas including kitchen, study areas, meeting rooms and laundry rooms. The project integrated mass-timber into the main common areas for the project, which provided open spans and beautiful architectural details, this hybrid method blended seamlessly together to create a stunning project.

Technical Innovation & Sustainability

360 VCM spearheaded this innovative partnership with Scott Builders Inc. as the GC and ROC Modular as the modular supplier. The project achieved step-code 4 of the BC Energy code, receiving exceptional ratings for energy efficiency and environmental design. Utilizing a modular construction process allowed for a faster schedule while minimizing waste and maximizing efficiency during construction. The project was designed to achieve a high level of energy performance by applying passive design principles, and the goal for the project was to increase the overall performance of the building through sustainable construction materials and improved energy efficiency. The hybrid integration of modular and mass timber for the project provided technical innovation and a beautiful architectural design for the finished building.

Cost Effectiveness

Modular construction provided a fast-track schedule which reduced overall project cost and enabled Selkirk College to meet the needs of both students and the community. High-quality modular student housing is a critical element for learner success and the completed project will result in better outcomes across the institution. Due to the Interior BC location of this project and a lack of trade availability in the area, modular construction provided the best option and lots of design consideration was given to completing as much in the factory as possible. Building in the ROC Factory reduced the need for trade workers and allowed the project to be completed faster and more cost-effectively. All interior finishes were completed in the factory before delivery, and all furnishings were installed, with a high degree of finish.

More from Modular Advantage

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.

LifeArk: Disaster-Resilient Housing from Recycled Plastic and 100-year-old Technology

Wee compares LifeArk’s housing units to Yeti coolers, as they are built similarly. Each component takes 15 to 20 minutes to manufacture, has an R-value of 40, and includes molded slots and chases for wiring, plumbing, fire sprinklers, and other utilities.

Building the Future of Modular Edge Infrastructure

The edge data center market is expanding rapidly, driven by the surge in AI workloads, IoT adoption, and the need for localized compute power. In these environments, sustainability, scalability, and reliability are non-negotiable. Cooling is among the most complex challenges for operators—and one of the most decisive factors in long-term success.

Accelerating Light-Gauge Steel Construction: A Semi-Automated Digital Workflow for Off-Site Projects

For construction professionals, the message is clear. By adopting semi-automation and digitalization, companies can deliver projects faster, more accurately, and more profitably, while also building stronger collaboration across teams. The approach is not about replacing people with machines, but about empowering people with better tools and processes.

Why Modular Data Centers Are Gaining Momentum

Artificial intelligence, high-performance computing, and edge applications push the limits of traditional “stick-built” data centers. They take years build, often struggle with high density workloads, and aren’t optimized for deployments near end users. Modular data center platforms are purpose-built to address these challenges, offering flexibility and scalability to adapt to evolving technologies, while opening new opportunities for the modular construction industry.

Supply Chain Innovation in Action: 5 Habits Every Modular Leader Should Practice

By applying these principles to supply chain practices — collaborative planning, strategic procurement, scenario modeling, digital tools, and transparent forecasting — construction leaders can build value chains that are not just efficient and agile, but truly innovative.

Exploring the Role of Modular Integrated Construction (MiC) in Advancing Circular City Principles – A Survey of Stakeholder Perspectives

The survey findings highlight the significant potential of Modular integrated Construction (MiC) in advancing the development of circular cities. By reducing costs, accelerating construction timelines, and minimizing waste generation, MiC offers a promising approach to sustainable urban development.

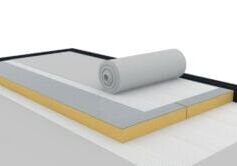

The Use of MS POLYMER™-Based Sealants and Adhesives in Modular Building

These products combine flexibility and elastic recovery with excellent adhesion to different substrates and have already shown their usefulness in traditional construction. Now it’s time for them to be put to use in the modular construction industry.