European Company iQ Module Bets The Future on Shared Tech, Tools, and Partnerships

Kris Droszcz is the founder and CEO at iQ Module, partner at iQ Module|Bud-Invest Group, and business development manager and leading architect at the architectural studio Rebel Concept.

Kris Droszcz comes from a family of architects and engineers, as his father (who still works as an architect) and grandfather before him. Jokingly, he calls it the family curse. But as the CEO and founder of iQ Module and Rebel Concept, you could say his curse is now a real blessing for the modular construction industry. iQ Module—based out of Gdansk, Poland—has grown exponentially as a company, with offices in Germany and Denmark. The company has also embarked on an ongoing joint venture and partnership with Roger Krulak of FullStack Modular for projects in the U.S. and around the globe.

Design-wise, iQ Module has now developed over 200 projects since its inception as a spin-off of Rebel Concept in 2009. Their first project, a public bid on a six-story modular building in Gdynia, Poland, launched them into the world of modular construction.

As Droszcz puts it, it was quite the struggle as they had to not only translate zoning regulations and specs from other countries, to even reaching out to local construction companies like Marbud and Studio Kwadrat to help them design and construct the first ever modular building in the region.

“We had to find solutions across Europe and the United States, wherever we were traveling or reading about, and trying to make the building permit and the technical specs accurate, according to our local coding,” he said. “For the second bid, there was no one to apply for building the building because no one knew how to build this kind of structure. So we figured, ‘we can make a team and build it ourselves.’”

The team won a number of design awards for their innovative approach using modular building, giving them a platform to continue working in the industry. iQ Module and its partners have now designed and developed about 80 modular-specific projects, varying from three-story residential buildings to high-rise buildings for hospitality, student housing, and multi-family homes.

Say ‘Yes’ and Figure Out The Rest

The philosophy of saying yes to projects and working in partnership with others has served the business well over the past few years, especially when iQ was looking at how to pivot during the pandemic.

“We don’t have a limit. Some say, ‘the sky is the limit,’ but I don’t see a limit. You know, we can do Mars, or the Moon,” he joked. “But, that’s the best way to work. Don’t have any boundaries. Team up. Share. Learn from your failures, learn from your partners, and improve your technology by working together.”

As COVID-19 paused travel across the world, Droszcz and his company brainstormed ways to continue the expansion of iQ Module—which was poised at the time in 2020 to start projects in the U.S. They were cut off from their clients, says Droszcz, and couldn’t bring either materials or staff over to continue projects in the States.

“We had to figure out what to do, not as a huge production company, but to provide our design services to others, and partner remotely with a lot of companies to use their facilities and their resources to support any local market that we want,” he said.

That’s where the shift happened, where they started embodying what they consider to be the future of modular construction and the industry at large.

“Sharing is the future for all of us,” says Droszcz. “This is for all industry’s sake, and what we figured is the best to do.” Ultimately, the firm’s belief in striking partnerships across the globe has led to its largest partnership to date.

In the U.S., iQ Module is working with FullStack Modular to develop projects in California and New York. In Asia and the rest of the world? Kris and his team have some projects in the works there too—including a very large project in Saudi Arabia, the first of its kind in the Middle East. Details are mum for now, but you can expect to see some news soon.

The philosophy of sharing not only business, but clients, projects, and designs would not have been possible without building information modeling.

BIM is the Backbone of iQ Module

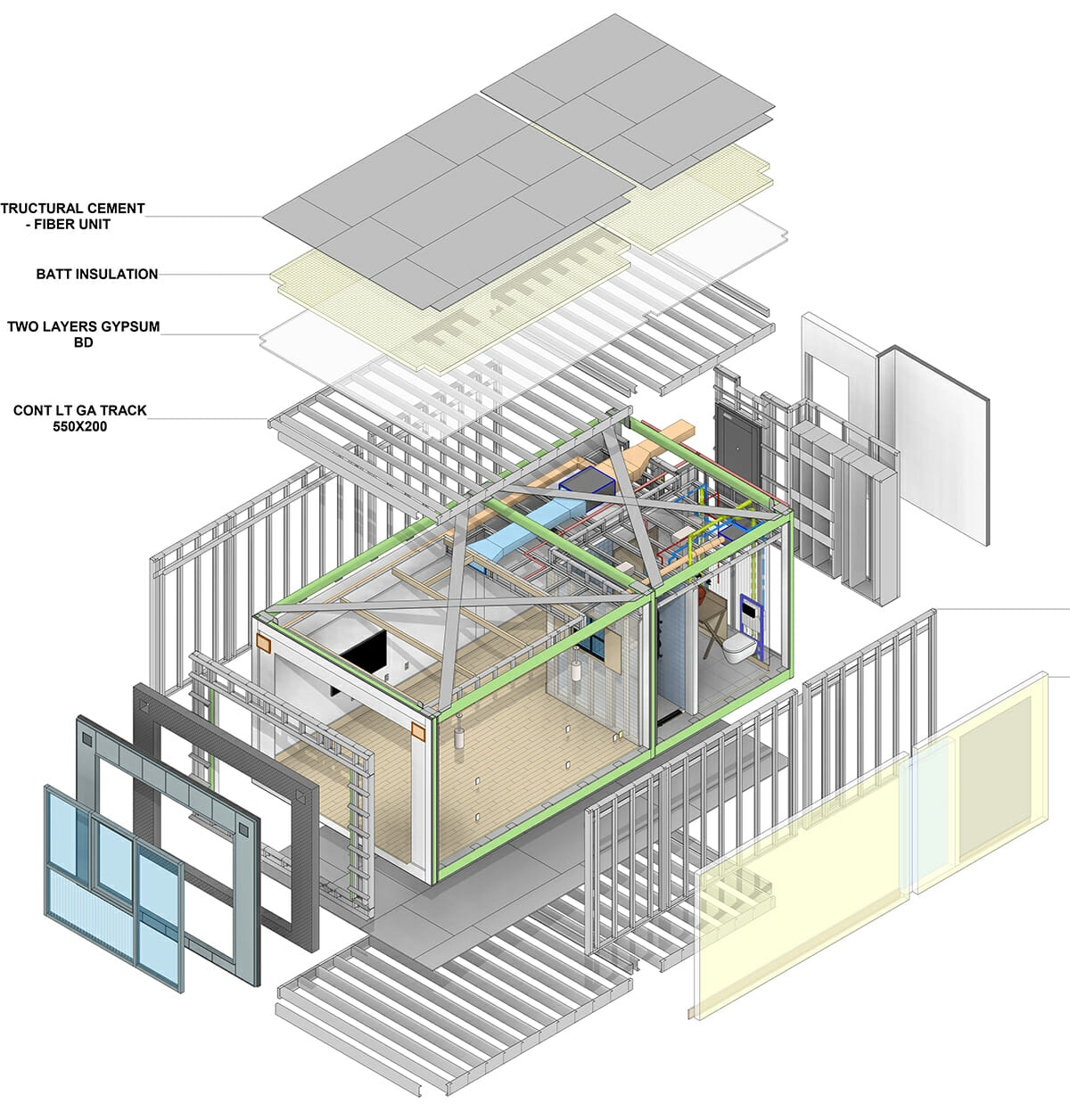

Over the years, iQ Module has evolved to be an all-in-one solutions based company for anyone interested in construction. For them, business is more than just developing designs, structural plans, and ensuring code compliance, leaving the rest up to general construction companies on the ground. BIM is woven throughout every step that iQ Module takes with the team when working on a new project, such as:

- Developing architecture plans alongside engineers and local code specialists

- Providing information on design loads, construction materials

- Existing climate concerns such as seismic loads, flooding, wind loads, and more

- Furniture production and interior design

The execution of a digital twin is crucial, says Droszcz, to see how a building will coexist with a surrounding neighborhood and remaining resilient to any ground conditions unique to the region.

It’s also one that iQ Module has bet its future on.

“I cannot imagine myself building anything today without a well-prepared design containing all the information and modeled elements of the building,” said Droszcz. “For us, it’s the integrity of the whole build process. So you can’t say it’s an add-on to your process. This is your process. This is how you should process the building design to execution.”

It has been quite a few years since the industry on the whole has evolved from using pen and paper to produce blueprints. Nowadays, tools like Autodesk Revit are now the most cost-effective way to execute a building from start to finish. The ability to have dynamic changes reflected in real time can mean the difference between meeting budget guidelines or spending a lot of capital to compensate for a small mistake.

“The design is the first thing that you have to invest the most in. If you don’t think that you have to spend a lot of money on the design process and preparation for the project, you’re going to fail,” says Droszcz.

Tack on augmented reality or VR tools, and it becomes possible to see yourself in a building of your own making. For example, you can manipulate the view of the steel structure of a high-rise hotel building, or look at how a material choice affects a multi-story residential building right in front of you.

The Future Is More Than Just Industry Growth

Alongside the technological advances made in the industry, Droszcz is hopeful that modular construction will take a larger piece of the pie. A world where 30 percent of the market is solely modular based building would be great, he says. And part of that is tied to ubiquity of BIM, which allows for companies like iQ Module to be successful through repetition and efficiency.

“We want to be able to listen to what the market needs and, and be responsive to what’s going on around us,” he says. “I think the best strategy is to listen to the world…[and to] get as efficient of a repeatable structure and product as you can, that you can also change easily.”

That said, there are just some things that you cannot escape, like meeting all the relevant zoning requirements set out by the city, state, and country for each project. When you layer on environmental or particular ground conditions, it becomes more than just making sure you check off all the boxes for compliance. Which can be challenging on top of simply designing a project, says Droszcz.

But on the whole, these challenges have not stopped iQ Module from growing. On top of two new offices in Denmark and Germany, the group has expanded to a staff of over 320 people. There are also the modules themselves, which have increased ten-fold per project, with about 1200+ modules scheduled to be designed by the Denmark office alone in 2023.

Over the next five years, iQ Module is looking to become one of the biggest modular building and design companies in the industry as well as internationally. One sign that they are well on their way is the reception to Droszcz’s talk at the MBI European Summit in October of 2022. While iQ Module’s work is largely based in the Northern Hemisphere, Droszcz says he was surprised by the worldwide interest.

He’s taken calls from interested parties from South American countries that want to work with iQ Module—and not just to design buildings. Some firms are looking for help in setting up tech solutions like BIM in existing facilities or to have iQ Module work in tandem with other companies’ R&D teams. All these requests fall in line with Droszcz’s business philosophy of sharing knowledge and developing partnerships in order to grow the modular building industry.

What to Expect from iQ Module at World of Modular

This is iQ Module’s fourth year attending World of Modular and Droszsz’s second time speaking. Combined with the 40th year anniversary, he is hoping this year will be bigger than ever. In fact, World of Modular has been one of the best networking opportunities for Droszcz and his team.

“[Attending] was one of the best decisions that we could make internationally for developing our contacts,” said Droszcz. “Through World of Modular, I have met a lot of my current partners, vendors, and most of the engineering company partners we work with.”

Droszcz is scheduled to lead a breakout session titled “How to BIM Your Project the Right Way!” He says the talk will feature not only case studies on how to use BIM effectively, but also 3D printed models, and opportunities for the audience to use AR and VR to interact with building models. He is also hoping to provide sneak peeks into upcoming iQ Module projects with FullStack Modular.

iQ Module will be at Booth #706 and #708 in partnership with FullStack Modular talking about their all-in-one modular integrated solutions.

About the Author: Karen P. Rivera is a freelance writer and editor with a passion for storytelling. She is a former United Nations-based reporter, with experience covering international breaking news, venture capital, emerging healthcare tech, and the video game industry.

More from Modular Advantage

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.

LifeArk: Disaster-Resilient Housing from Recycled Plastic and 100-year-old Technology

Wee compares LifeArk’s housing units to Yeti coolers, as they are built similarly. Each component takes 15 to 20 minutes to manufacture, has an R-value of 40, and includes molded slots and chases for wiring, plumbing, fire sprinklers, and other utilities.

Building the Future of Modular Edge Infrastructure

The edge data center market is expanding rapidly, driven by the surge in AI workloads, IoT adoption, and the need for localized compute power. In these environments, sustainability, scalability, and reliability are non-negotiable. Cooling is among the most complex challenges for operators—and one of the most decisive factors in long-term success.

Accelerating Light-Gauge Steel Construction: A Semi-Automated Digital Workflow for Off-Site Projects

For construction professionals, the message is clear. By adopting semi-automation and digitalization, companies can deliver projects faster, more accurately, and more profitably, while also building stronger collaboration across teams. The approach is not about replacing people with machines, but about empowering people with better tools and processes.

Why Modular Data Centers Are Gaining Momentum

Artificial intelligence, high-performance computing, and edge applications push the limits of traditional “stick-built” data centers. They take years build, often struggle with high density workloads, and aren’t optimized for deployments near end users. Modular data center platforms are purpose-built to address these challenges, offering flexibility and scalability to adapt to evolving technologies, while opening new opportunities for the modular construction industry.

Supply Chain Innovation in Action: 5 Habits Every Modular Leader Should Practice

By applying these principles to supply chain practices — collaborative planning, strategic procurement, scenario modeling, digital tools, and transparent forecasting — construction leaders can build value chains that are not just efficient and agile, but truly innovative.

Exploring the Role of Modular Integrated Construction (MiC) in Advancing Circular City Principles – A Survey of Stakeholder Perspectives

The survey findings highlight the significant potential of Modular integrated Construction (MiC) in advancing the development of circular cities. By reducing costs, accelerating construction timelines, and minimizing waste generation, MiC offers a promising approach to sustainable urban development.

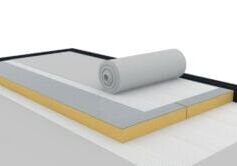

The Use of MS POLYMER™-Based Sealants and Adhesives in Modular Building

These products combine flexibility and elastic recovery with excellent adhesion to different substrates and have already shown their usefulness in traditional construction. Now it’s time for them to be put to use in the modular construction industry.