Maximizing Modular Fabrication

About the Author: Nick Gomez of Lowney Architecture has more than 15 years of experience working on multi-family housing and modular projects for nonprofit and for-profit clients. As the Oakland, Calif.-based firm’s Multi-family Studio Director, Nick has managed award-winning projects from design development through construction administration.

An increasing number of projects across different markets use modular construction. The modular building approach allows projects to capture the efficiencies gained by integrating design, manufacturing, and construction technologies without compromising aesthetic intent. When working toward a successful modular project, it is ideal to have experienced architecture, engineering, and contractor team members.

Projects using off-site modular construction must comply with the same building codes as conventional on-site construction. However, many states require separate permitting for the off-site factory and the on-site work. This process involves coordination between the architecture, engineering team, and factory.

Respect The Timelines And Deliverables

Modular buildings are similar to traditional on-site buildings in appearance and performance. One significant advantage of modular buildings is the shortened timeline, which delivers cost savings. This is because the modular pieces are constructed in a climate-controlled factory, which removes the possibility of weather-related delays.

This protected working environment increases efficiency allowing the structure to be built faster and cost less. Also, having a separate workspace from the building site allows for concurrent building. While the site foundation or podium is being constructed, the building components are simultaneously built at the off-site factory.

It is essential to establish a design freeze using a modular construction approach because of the factory production schedule and process. Design changes late in the process can be costly and require permit drawings modification and impact factory shop drawings. Unlike traditional construction processes, up-front decision-making and design freezes are critical for the modular construction processes, leaving little time in the schedule for alterations.

The modular prototype phase allows the owner, architect, and factory to set the basis of the design for production. This happens ahead of full production and enables the team to review, approve the design, and make small minor modifications to finish details and materials before the start of procurement and full production. With the fast pace of factory production, the design team is not often capable of reviewing every module. It relies on the contractor or third-party reviewer to inspect, so having the approved prototype is critical as a basis to review mods while in production.

Parameters

When designing a modular building, architects should address not just the design of a structure and its constitutive components; they should also be intentional about the process by which these are fabricated, transported, and connected. The design of individual modules may be affected by the manufacturing standards and assembly process of a particular facility. At the same time, the parameters of the design will dictate the ideal execution of those processes. For example, designers must look at the size of individual unit types and modules and how those sizes can be optimized across multiple unit and module types to increase production efficiencies.

When designing for modular construction, the project team should shift perspective to the building as a connected component system. This can help open more modularization possibilities, leading to a more iterative and less linear design process. The modularity concept should ideally be embedded in and inform all phases of a project, not just the construction phase and lead to a more collaborative design and delivery method.

Warranty And Liability

When implementing modular construction, project teams will consider some unique issues related to financing and liability. For example, factories want a warranty to start when production is complete and not building assembly. It always becomes a negotiating point with the contractor and owner.

Most vertical construction takes place off-site, which shifts the typical construction project balance based on the expected percentage of labor versus material. Modular construction also involves particular risks that need to be considered and insured against.

Understanding The Timeline For Deliverables

As outlined, modular construction is a primary benefit because it allows for building components to be constructed simultaneously that site work is being completed. Once the fabrication of the modules and site operations begin, the contractor should maintain regular communication with the modular manufacturer to ensure the schedule is maintained. According to the schedule, this early communication will ensure that the parallel processes are closely coordinated and proceed in step with each other.

Suppose the team respects the early decision making and design freezes set by the factory schedule. In that case, all of these factors are understood and met, depending on the project’s complexity. In that case, the team should see a construction schedule reduction of 20-40 percent.

More from Modular Advantage

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

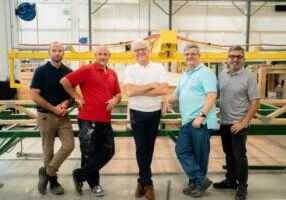

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.

ModMax: Redefining Modular Construction with Confidence and Precision

ModMax was born out of frustration—frustration with five persistent pain points in modular construction: Permitting bottlenecks. Production delays. Rigid designs. Disconnect between “the office” and the field. Lack of transparency and communication.

LifeArk: Disaster-Resilient Housing from Recycled Plastic and 100-year-old Technology

Wee compares LifeArk’s housing units to Yeti coolers, as they are built similarly. Each component takes 15 to 20 minutes to manufacture, has an R-value of 40, and includes molded slots and chases for wiring, plumbing, fire sprinklers, and other utilities.

Building the Future of Modular Edge Infrastructure

The edge data center market is expanding rapidly, driven by the surge in AI workloads, IoT adoption, and the need for localized compute power. In these environments, sustainability, scalability, and reliability are non-negotiable. Cooling is among the most complex challenges for operators—and one of the most decisive factors in long-term success.

Accelerating Light-Gauge Steel Construction: A Semi-Automated Digital Workflow for Off-Site Projects

For construction professionals, the message is clear. By adopting semi-automation and digitalization, companies can deliver projects faster, more accurately, and more profitably, while also building stronger collaboration across teams. The approach is not about replacing people with machines, but about empowering people with better tools and processes.

Why Modular Data Centers Are Gaining Momentum

Artificial intelligence, high-performance computing, and edge applications push the limits of traditional “stick-built” data centers. They take years build, often struggle with high density workloads, and aren’t optimized for deployments near end users. Modular data center platforms are purpose-built to address these challenges, offering flexibility and scalability to adapt to evolving technologies, while opening new opportunities for the modular construction industry.

Supply Chain Innovation in Action: 5 Habits Every Modular Leader Should Practice

By applying these principles to supply chain practices — collaborative planning, strategic procurement, scenario modeling, digital tools, and transparent forecasting — construction leaders can build value chains that are not just efficient and agile, but truly innovative.

Exploring the Role of Modular Integrated Construction (MiC) in Advancing Circular City Principles – A Survey of Stakeholder Perspectives

The survey findings highlight the significant potential of Modular integrated Construction (MiC) in advancing the development of circular cities. By reducing costs, accelerating construction timelines, and minimizing waste generation, MiC offers a promising approach to sustainable urban development.

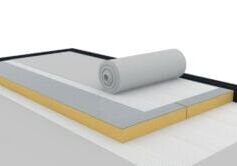

The Use of MS POLYMER™-Based Sealants and Adhesives in Modular Building

These products combine flexibility and elastic recovery with excellent adhesion to different substrates and have already shown their usefulness in traditional construction. Now it’s time for them to be put to use in the modular construction industry.