Oldivai on 31st – Modular Housing, Rinse and Repeat

What Makes Oldivai Different?

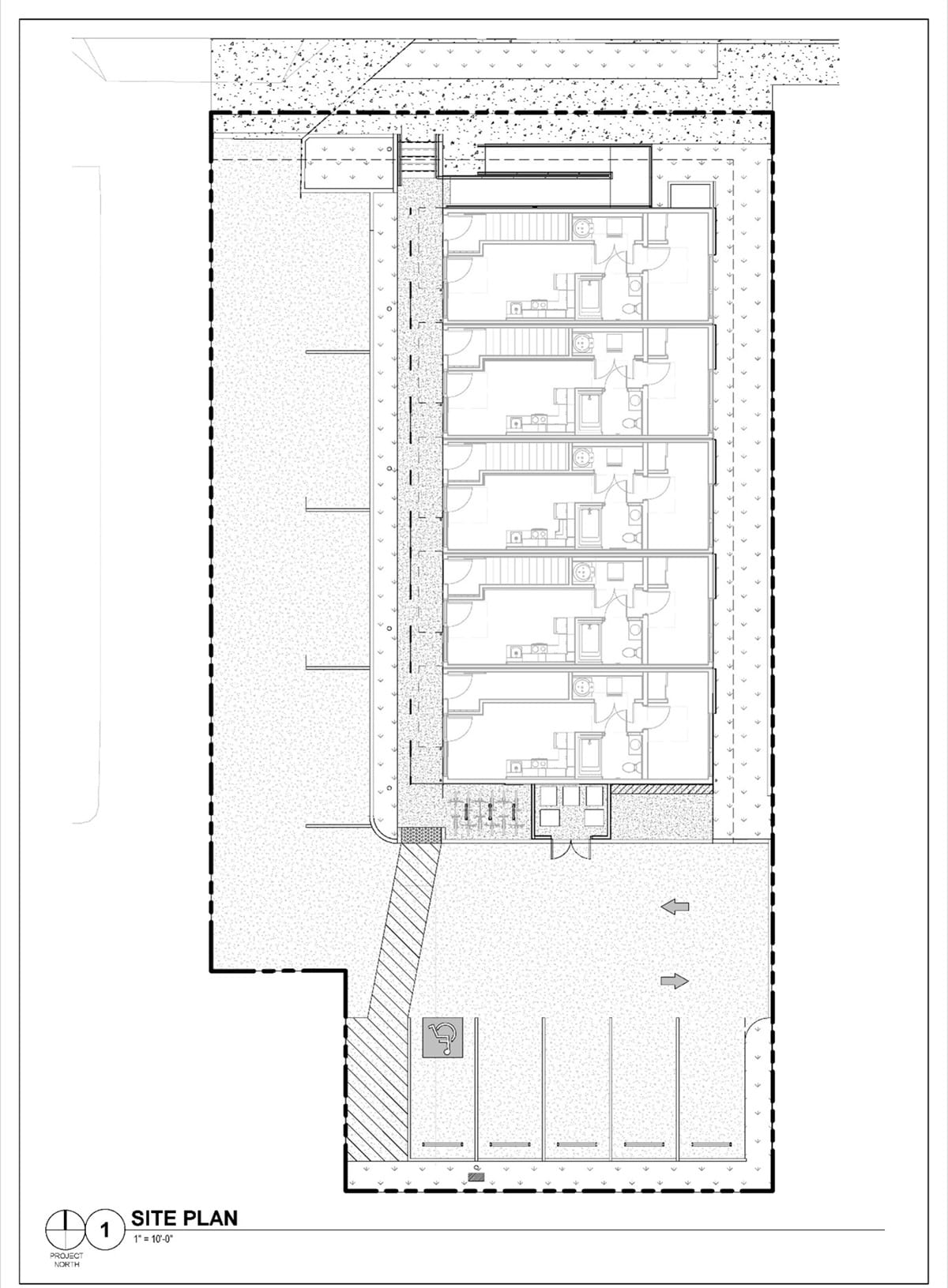

Fast and high-quality construction rarely go together—until now. Oldivai on 31st (aka Project Zero) redefined modular housing by combining speed with exceptional standards. Developed as the inaugural project for Oldivai Capital, this 7,280-squarefoot, three-story complex wasn’t just designed to address Spokane’s growing housing shortage, it was created to serve as a prototype for scalable, repeatable workforce housing solutions.

With a “kit-of-parts” approach, Oldivai on 31st demonstrated how a predesigned layout could deliver consistent programming and rapid deployment. This project didn’t just match the site; it set a standard for matching the design to sites across multiple locations. With five additional projects and a larger multi-unit complex slated for 2025, this proof of concept has already paved the way for future developments.

Quick Facts

- Project Name: Oldivai on 31st

- Location: Spokane, Washington

- Building Type:

Multifamily Apartments - Number of Units: 10

- Number of Modules: 15

- Total Area: 7,280 square feet

- Timeline:

- Groundbreaking: July

31, 2023 - Modular Set: Jan. 29 – Feb. 1, 2024 (4 days)

- (TCO) Substantial

Completion: July 2, 2024 (310 days from site start)

- Groundbreaking: July

- Total Construction Cost: $2,692,850

Why Modular? Why Now?

Traditional construction simply can’t keep up with the rising demand for housing. Modular construction offers not just a faster solution but a smarter one. Oldivai on 31st tackled inefficiencies head-on, sidestepping weather delays and labor shortages to deliver a completed project in under a year. But this wasn’t just about speed. The real challenge was scalability: could modular construction deliver consistent quality across future developments? Project Zero answered that with a resounding yes, setting a new standard for efficiency, precision, and repeatability in multifamily housing.

Designing for Precision and Efficiency

At Oldivai on 31st, efficiency meant doing things right from the start. Every stage of the process was optimized to maximize quality while minimizing delays. Building modules in a climate-controlled factory protected materials from Spokane’s unpredictable weather. This method reduced waste, ensured tighter tolerances, and allowed interiors, mechanical systems, and finishes to be 80% complete before shipping. Modules arrived on-site nearly move-in ready. Plumbing, electrical systems, and finishes were pre-installed, leaving minimal onsite labor. The modules were craned into place in just four days, bypassing typical delays caused by weather or onsite inefficiencies. From groundbreaking to substantial completion, Oldivai was finished in 310 days, shaving weeks off traditional construction timelines.

Challenges and Lessons Learned: Smarter Construction Every Step of the Way

Every challenge faced during the development of this project became an opportunity to refine modular construction processes. These obstacles not only shaped the Project Zero’s success but also established a framework for improving future developments.

Think Lifecycle, Build Smarter

The journey from factory fabrication to tenant move-in requires planning for every phase of a building’s lifecycle. At Oldivai, the team embraced a “start with the end in mind” philosophy. Features like standardized crawl space and attic access simplified future maintenance, ensuring the building functioned efficiently long after completion. This forward-thinking approach highlighted the importance of designing for long-term usability—not just immediate results.

Streamlining Communication

Early misalignments between architectural and modular plans caused delays and confusion, underscoring the need for clear documentation and communication.

- Solution: A unified labeling system and centralized digital repository ensured that all stakeholders—from architects to contractors—worked from the same, up-to-date information.

- Result: Improved consistency across teams, reduced miscommunication, and faster resolutions to onsite challenges.

Fire Safety and Critical Systems Coordination

Ensuring compliance with fire safety requirements was a recurring challenge. Factory and onsite integration revealed the need for better coordination in critical systems like plumbing and fire suppression.

- Solution: The team expanded zones for fire suppression systems and standardized plumbing bays to simplify installation. Detailed firestopping designs were also integrated into the architectural set to meet inspection standards.

- Result: These adjustments avoided costly delays and have become a new standard for future modular projects.

Continuous Improvement

Modular construction thrives on iteration. Every success and setback at Oldivai informed a scalable framework for the future. Lessons weren’t just learned—they were applied, proving that modular isn’t just about speed but about smarter, more reliable results.

- Standardization for Simplicity: Consistent fixtures, finishes, and system designs reduced variability and accelerated production.

- Flexibility for the Unexpected: Challenges like fire safety revisions reinforced the importance of adaptability, ensuring that future projects are equipped to handle surprises.

Continuous Improvement

The insights from Oldivai on 31st offer practical guidelines for future modular developments:

- Design for the Lifecycle: Plan beyond completion—incorporate features that simplify maintenance, upgrades, and tenant satisfaction.

- Invest in Systems: Clear documentation, precise Oldivai on 31st Level 1 Floorplan labeling, and real-time updates prevent errors and build trust across teams.

- Standardize for Scalability: Uniformity in fixtures and finishes ensures consistent quality and reduces variability in production.

- Embrace Feedback: Every project provides lessons. Use them to refine processes and create smarter solutions.

Cost Effectiveness

With a total cost of $2,692,850, Oldivai on 31st demonstrated that cost savings don’t come from cutting corners—they come from doing things right. Time is money, and Project Zero proved that faster construction saves both.

Conclusion: Building Better, Smarter, and Faster

For Jackson | Main Architecture and Oldivai Capital, Project Zero isn’t just a success—it’s a promise. This project demonstrates that better, faster, and smarter construction is achievable without compromising durability or design. For tenants, it offers a home they can trust, built to the highest standards. More than a single modular project, Oldivai on 31st is the foundation of a larger vision—one that extends far beyond Spokane and will shape housing solutions for years to come.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.