Ingenious System Assembles Buildings with Concrete Superstructure in Weeks

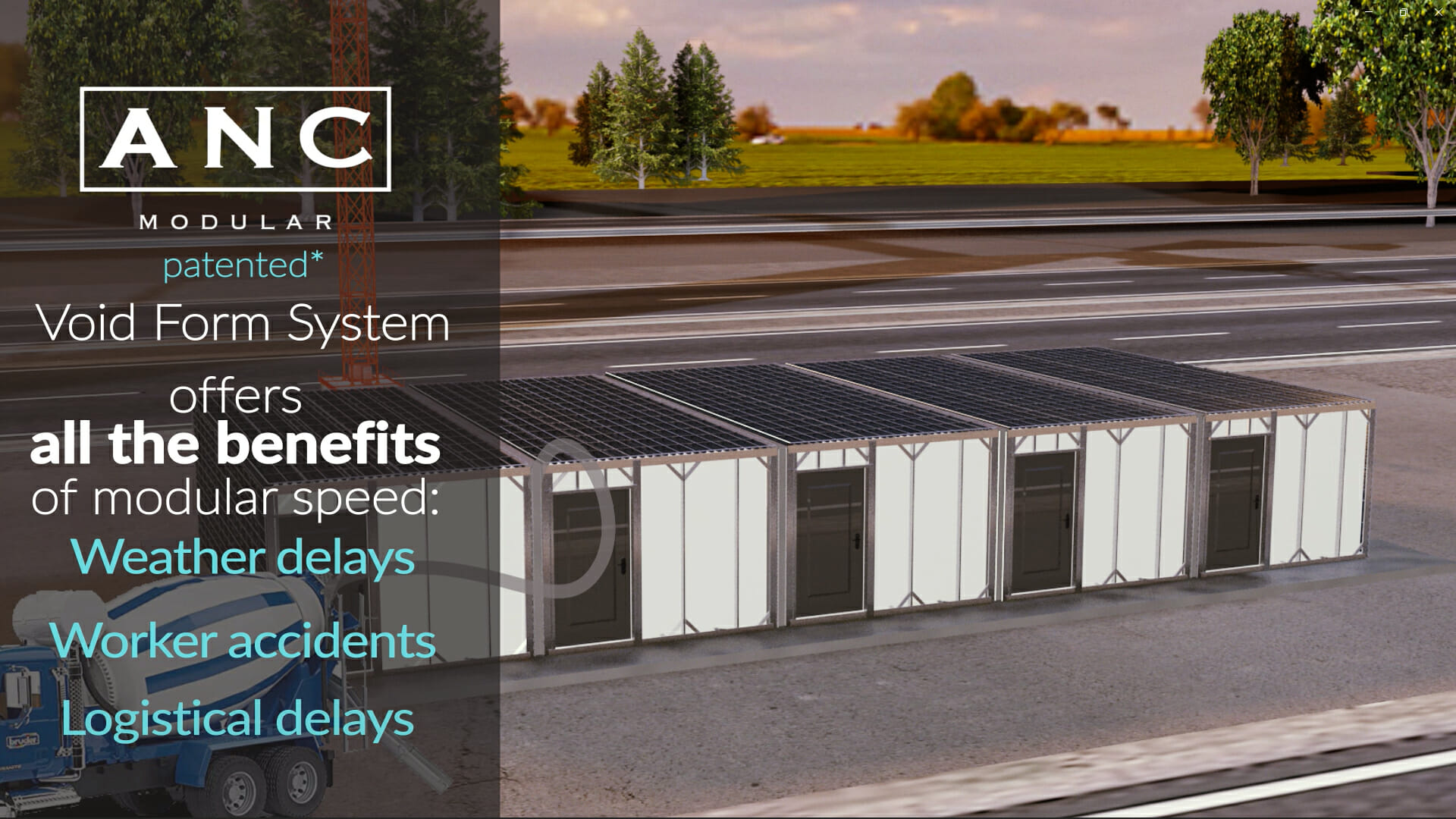

New technology being implemented by Andrew Neill Construction (ANC), a construction company in Canada, allows multi-story housing developments to be completed in weeks instead of months. Imagine housing developments being completed with only two weeks of on-site construction. With ANC’s Void Form System, it’s possible.

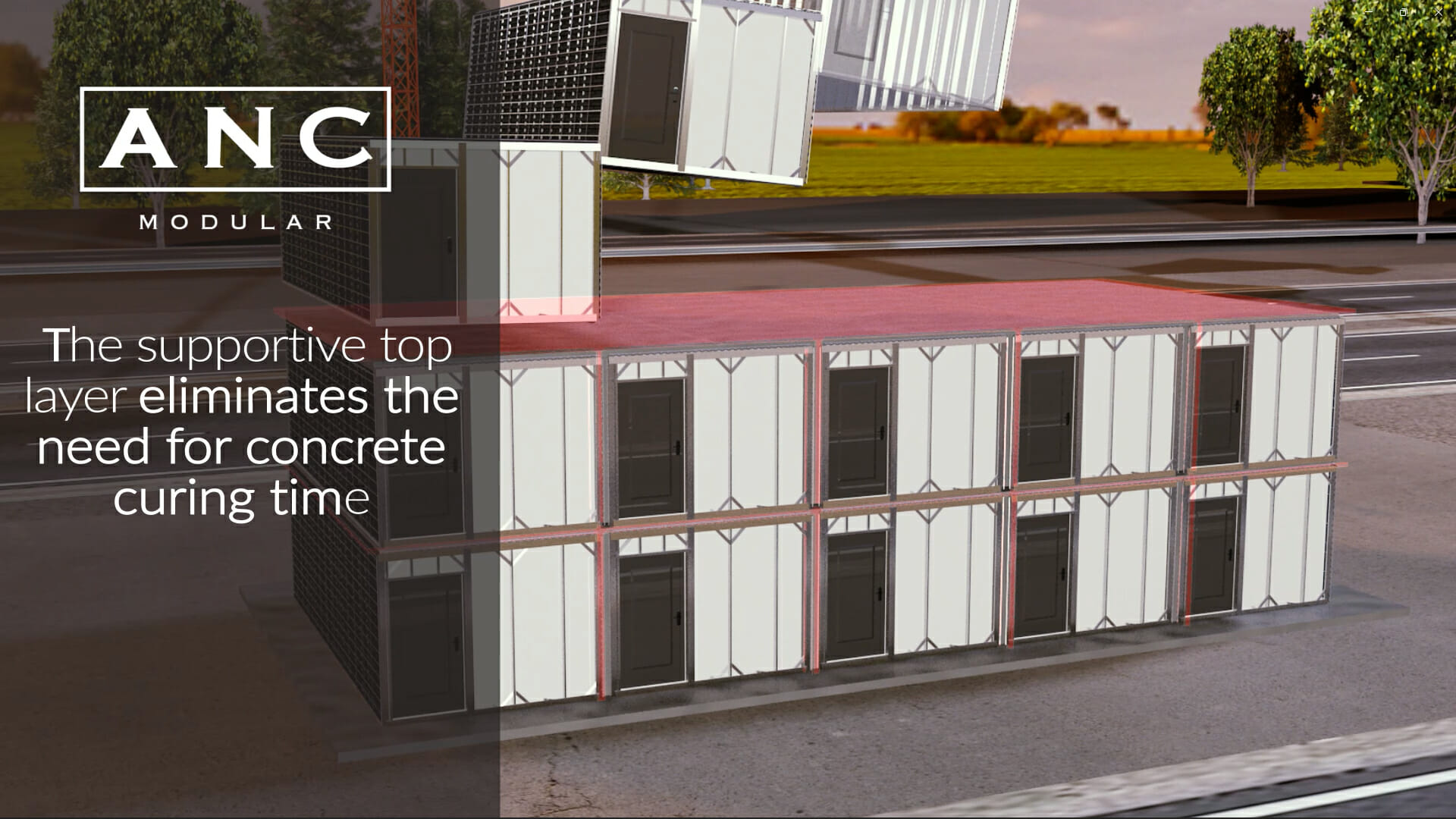

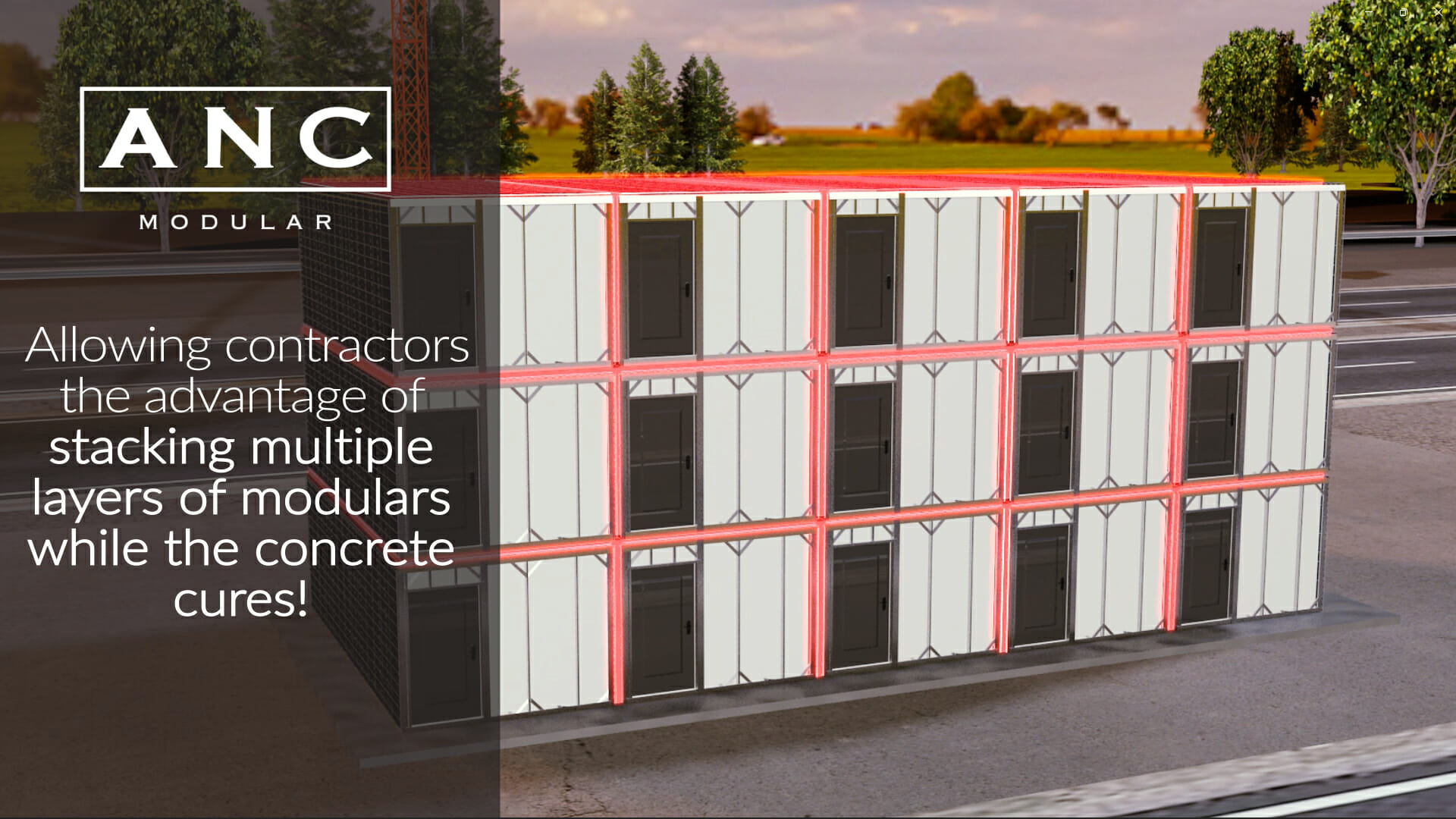

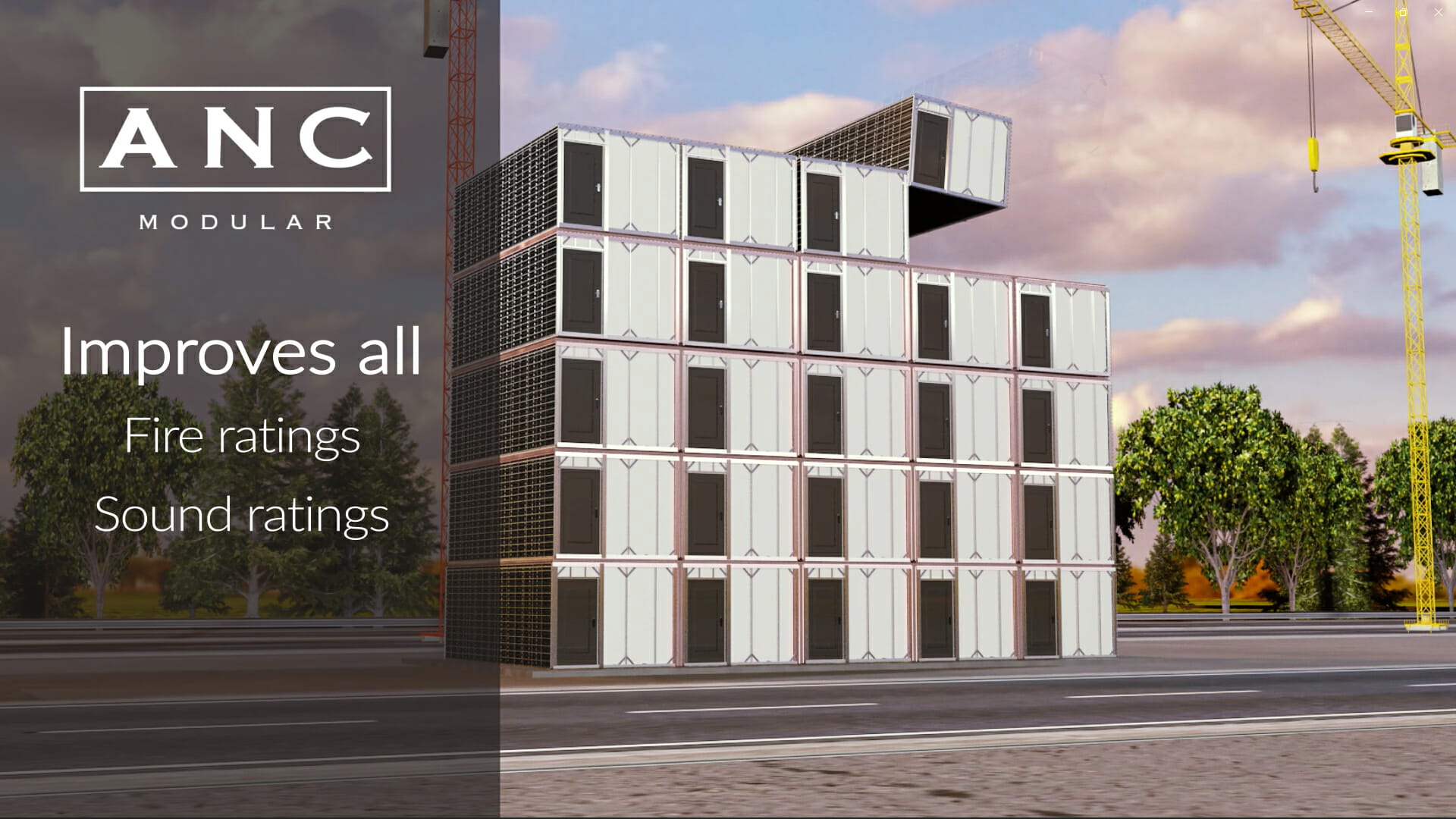

The ingenious system uses stackable modules to provide the forms for the concrete superstructure. The concrete is poured into the voids between the modules, and another layer of modules can be immediately stacked on top, without waiting for the concrete to cure.

The fully finished modules are built off-site while the overall project is being reviewed and approved for permits. In Canada, modular units of this type do not fall under standard building codes. Therefore, they can be constructed while the plans for the building are being reviewed.

Once permits are issued, the modular units are ready to be shipped and stacked. Here’s where the magic happens: After the units have been stacked, concrete is poured into the voids, creating a strong structural frame for the building. Additional module layers can be stacked on top of existing units before the concrete cures because of the structural steel elements in each unit.

This patent-pending system provides an opportunity for quick construction of concrete formed midrises and highrises. Andrew Neill, the President and CEO of ANC, thinks the design could be useful for hurricane ravaged areas, earthquake-prone regions, as well as areas rocked by war, such as the Ukraine.

Neill developed the idea for the system when another contractor approached him about finding a better way to construct hospital rooms using modular construction. The contractor was looking to find cost savings through speed, quality, and efficiency. He thought modular construction was the answer, but the project called for a concrete superstructure. The contractor’s idea was to form and pour the structure, then slide the finished modules in from the side. Neill thought that wouldn’t be cost effective.

Neill’s next idea was to set the units first, then pour the concrete. After many sleepless nights and meetings with structural engineers, he developed a system that could work. The process has taken about a year to develop.

How It Works

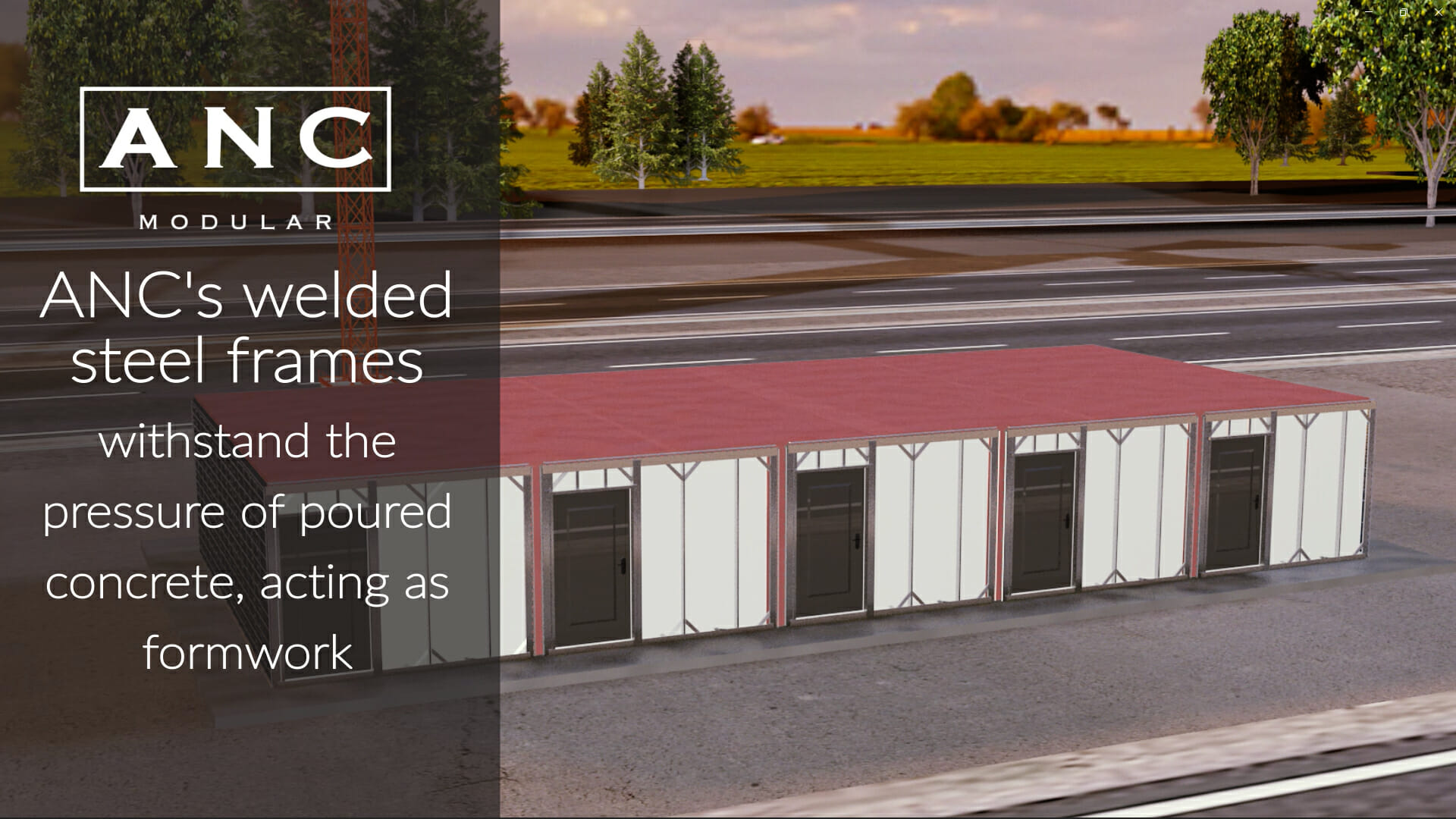

The modules are completely finished and assembled off-site. They come complete with insulation, electrical, plumbing, HVAC, drywall, millwork, flooring, lighting, and plumbing fixtures. The steel frame that surrounds each module is engineered to act as a structure of its own, as well as act as a concrete form that will provide additional structural strength once concrete is poured into it.

The modules stack on top of each other without any additional shoring or support and are bolted together. The structural steel frames are clad with corrugated steel and are ready to receive concrete in the vertical wall section, and also on top of the modules horizontally.

The next level of modules can be added almost immediately after the concrete is poured; no curing is required. When reinforcing steel bars are added and the concrete has cured, the weight of the building transfers to the concrete, changing the fire and structural ratings. This allows the system to be used for highrise applications, even in areas with strict structural codes, like California and Miami.

There are no special concrete mixes required and the concrete is pumped to each module using tower cranes and concrete pumps.

The system allows projects to meet the requirements for a concrete superstructure without having to use conventional forming methods, saving 98% of the costs related to forming, pouring, and stripping concrete.

The system’s only drawback may be that there’s more steel than necessary. But Neill says the time and cost savings far outweigh the cost of the redundant steel.

The Future

Andrew Neill started ANC in 2017 in Brantford, Ontario, near Toronto. He has 18 years of experience as a residential carpenter and superintendent on projects in Canada and the Caribbean.

The timing couldn’t have been better, as the Canadian federal government started a funding program for affordable housing called the Rapid Housing Initiative (RHI). ANC was granted several contracts for affordable housing projects for municipalities and indigenous communities in the area.

Although no projects have yet been completed using the system, Neill hopes to change that soon. The flexibility of the system allows it to be tailored to almost any project.

There’s seemingly no limit to how high the modules can be stacked. “All the fire rating and structural capacity is being placed on the concrete structure after it has cured, making the modules only a cosmetic fit-out at the end. They are used temporarily to eliminate the need for most of the concrete forming, and also eliminate the need for a conventional structural ‘core.’ You could, in theory, pour the walls and slabs, and stack fully finished modules concurrently, literally without stopping, until you reach the top, which could be over 100 stories.”

Neill sees this product best being used for midrise and high-rise buildings in coastal areas and those prone to earthquakes or other natural disasters. It would provide a way for a quick response to rebuild in an area after a disaster. He looks to get the product approved in the US soon, as well as expand its use to hospitals and healthcare buildings.

About the Author: Dawn Killough is a freelance construction writer with over 25 years of experience working with construction companies, subcontractors and general contractors. Her published work can be found at dkilloughwriter.com.

More from Modular Advantage

How Stack Modular Is Using AI to De-Risk Mid- to High-Rise Modular Construction

Artificial intelligence is no longer a future concept in modular construction—it is already reshaping how complex buildings are evaluated, designed, and delivered.

Gearing Up for the 2026 World of Modular

The Modular Building Institute (MBI) is bringing its global World of Modular (WOM) conference and tradeshow back to Las Vegas in April, and with it comes some of the industry’s best opportunities for networking, business development, and education.

New High-Rise Modular Apartment in Abu Dhabi Points Toward the Future of Multifamily Construction

Eagle Hills International Properties chose the BROAD Holon Building for a 16-story market rate apartment building in Zayed City, a central business district of Abu Dhabi. The project highlights the potential of the Holon system of volumetric modular construction to accelerate housing delivery.

MBI Announces First Ever Industry Apprenticeship Program in Collaboration with Marshall Advanced Manufacturing Center

MBI recently agreed to partner with Marshall Advanced Manufacturing Center (MAMC) to provide bona fide USDOL-approved apprenticeship programs for the industry.

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.