DORCE Designs and Exports Volumetric Modular Buildings to 6 Continents

DORCE offers “Convertible and eco-friendly” volumetric modular steel structures

Today we witness “convertible and eco-friendly” volumetric modular buildings stand out in industrialized construction with new construction technologies, new construction methods, and innovative materials, unlike those used in traditional building systems.

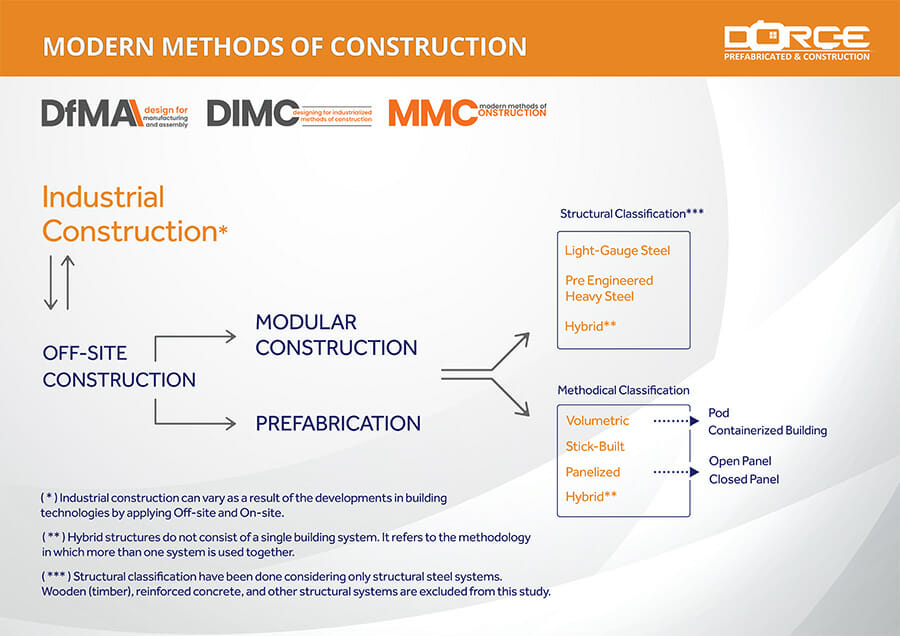

Prefabricated modular building elements offer high-quality projects with lower costs and optimized & accelerated construction programs. The concepts such as Design for Manufacturing and Assembly (DfMA) & Designing for Industrialized Methods of Construction (DIMC) constitute the most basic and modern elements of Off-site construction and Modern Methods of Construction (MMC).

Demand has been increasing in sectors such as education, entertainment, health services, and housing

Mobile life offers fast and practical solutions with prefabricated modular structures to all the sudden and changing needs of people far away from their homes in the most severe climatic conditions. Stable architectural solutions used in built-in building systems have

begun to be replaced seriously by modular building systems. Demand for modular building systems has been increasing day by day in many areas of our lives such as education, entertainment, health services, and housing.

In general, modular building systems can be classified as permanent and mobile modular buildings.

Permanent modular buildings

Permanent modular buildings include schools, hospitals, shopping malls, clinics, residences, housing units, vehicle inspection stations, police stations, warehouses, hangars, administrative buildings, office buildings, hotels, and dormitories.

Mobile modular buildings

Mobile modular buildings include caravans, trailers, tiny houses, modular containers, temporary emergency & disaster facilities, integrated refugee facilities / camps, worker accommodation camps, labour quarters, and mobile hospitals.

Volumetric modular buildings of DORCE can be used as a traditional accommodation as well as temporary – volumetric modular accommodation in disaster and war zones; they are also used as temporary residential camps or permanent accommodation facilities at construction sites, oil & gas, mining, drilling, offshore and pipeline sites.

Related Reading:

Advantages of Digital Prefabrication for the Modern Construction Industry

DORCE Prefabricated Building & Construction Industry Trade Inc. manufactures prefabricated modular building components directly with Building Information Modeling (BIM) and completes their assemblies completely digitally off-site.

This article details all the benefits realized through digital prefabrication and shows how other manufacturers can capitalize on this popular method of project deisgn.

Modular units manufactured in a controlled environment

Modular building systems, manufactured by DORCE, are used for projects that require rapid solutions and must be completed in harsh climatic and geographical conditions. The component of modular buildings manufactured in a controlled environment at the industrialized facility (factory conditions) and transported to the construction site as units and assembled at the place.

DORCE completes staff accommodation facilities in Kazakhstan with volumetric modular building system

Last year, DORCE has successfully completed construction of Copper Mine Staff Accommodation Facilities within the scope of the Aktogay Expansion Project in Kazakhstan.

Pre-manufactured containerized modular units are manufactured at the Dorce production plant in Turkey, delivered as flat-packed and each module is assembled at Dorce workshops in Kazakhstan. Thereafter, modules delivered to the site in Aktogay and erected side by side and stacked to create a complete structure.

The connection of all modular buildings is done at the construction site. They are immediately made weathertight to protect the interior and interconnected structurally. The finishes and mechanical connections are completed, and all systems are inspected and tested. Custom features such as site applied finishes, pitched roofs and other architectural treatments can be added to make the building a customized structure, ideally suited for its specific use.

10 modular buildings with 1,628 modules in total

Finally, the entire structure composes of 10 modular buildings consisting of 1,628 modules in total.

Building modules are demountable, transportable, and designed to allow an easy dismantling and erection for several times. Volumetric modular buildings of DORCE are designed to be assembled on the reinforced concrete columns with anchorages above the ground level.

Off-site construction at -40 degrees climate conditions

These types of building systems allow the rapid formation of larger interior volumes and larger structures by coming together of modules as volumetric structures. Copper Mine Accommodation Facilities Project of DORCE in Kazakhstan – Aktogay was completed with “volumetric” building systems in -40 degrees climate conditions.

Volumetric modular building systems offer plenty of advantages

The advantage of this method is that all conditions are under control since the manufacturing process takes place in the factory environment. Thus, the quality of the produced materials increases. Fire, sound, and thermal insulation can be made as desired and accordingly with the requirements of projects and customers. In addition, this Modern Method of Construction (MMC) saves time.

Volumetric modular construction provides many advantages to people as a part of today’s modern living spaces and offer practical solutions in accordance with the changing needs of people. Volumetric modular buildings are permanent or temporary structures that can be equipped with high-level technology, meet their own needs, even solve their sub-structural needs such as energy recovery and waste recycling. They are lightweight, easily assembled and disassembled and transportable from one location to another.

More from Modular Advantage

AoRa Development Aims for New York’s First Triple Net Zero Building Using Modular Methods

More cities are providing funding for newer infrastructure projects as long as they meet sustainability requirements. This is how modular can fit the bill, thanks to its lower waste production.

Developers and Designers: Lessons Learned with Modular Design

Modular construction is attractive to many developers because sitework and module construction can occur simultaneously, shortening the schedule and reducing additional costs.

UTILE: Putting Modular Building on a Fast Track

In Quebec, UTILE is taking the lead in creating affordable modular buildings to help decrease the student housing shortage. During the process, the company discovered what it takes to make the transition to modular building a success.

Sobha Modular Teaches Developers How to Think Like Manufacturers

With its 2.7 million square foot factory in UAE, Sobha Modular is bringing both its high-end bathroom pods to high-end residences to Dubai while developing modular projects for the U.S. and Australia.

RoadMasters: Why Early Transport Planning is Make-or-Break in Modular Construction

In modular construction, transportation is often called the “missing link.” While it rarely stops a project outright, poor planning can trigger costly delays, rerouting, and budget overruns.

Navigating Risk in Commercial Real Estate and Modular Construction: Insights from a 44-Year Industry Veteran

Modular projects involve manufacturing, transportation, and on-site assembly. Developers must understand exactly what they are responsible for versus what they subcontract. Risk advisors should research the developer’s contractors, subcontractors, and design-build consultants—especially the modular manufacturer.

Art²Park – A Creative Application of Modular and Conventional Construction

Art²Park is more than a park building—it’s a demonstration of what modular construction can achieve when thoughtfully integrated with traditional materials. The use of shipping containers provided not only speed and sustainability benefits but also a powerful structural core that simplified and strengthened the rest of the building.

Building Smarter: A New Standard in Modular Construction Efficiency

Rising material prices, labour shortages, expensive financing and tightening environmental rules have made conventional construction slower, costlier, and more unpredictable. To keep projects on schedule and within budget, builders are increasingly turning to smarter industrialized methods.

Resia: Breaking All the Rules

Resia Manufacturing, a division of U.S.-based Resia, is now offering prefabricated bathroom and kitchen components to industry partners. Its hybrid fabrication facility produces more precise bathroom and kitchen components (modules) faster and at lower cost than traditional construction. Here’s how Resia Manufacturing does it.

How LINQ Modular Innovates to Bring Modular To The Market in the UAE and Beyond

LINQ Modular, with an office and three manufacturing facilities in Dubai, is a modular firm based in United Arab Emirates. The company is on a mission: to break open the housing and construction markets in the Gulf Cooperation Council (GCC) area with modular.